Always fill the condensate trap with water and

place it on the boiler before powering up the

boiler.

For filling the condensate trap the hose between

de trap and the PRV has to be removed (trap

side). Make sure the hose is re-mounted after

filling the condensate trap.

Not placing or filling up the condensate trap may

cause flue gases to come into the installation

room and can lead to dangerous situations!

.

The condensate discharge system, pipework and fittings must be made of

plastic. No other materials may be used. The discharge duct must have a

gradient of 5 – 20 mm/m throughout its length. Condensate discharge via the

gutter is not allowed given the risk of frost and the possible damage to

materials

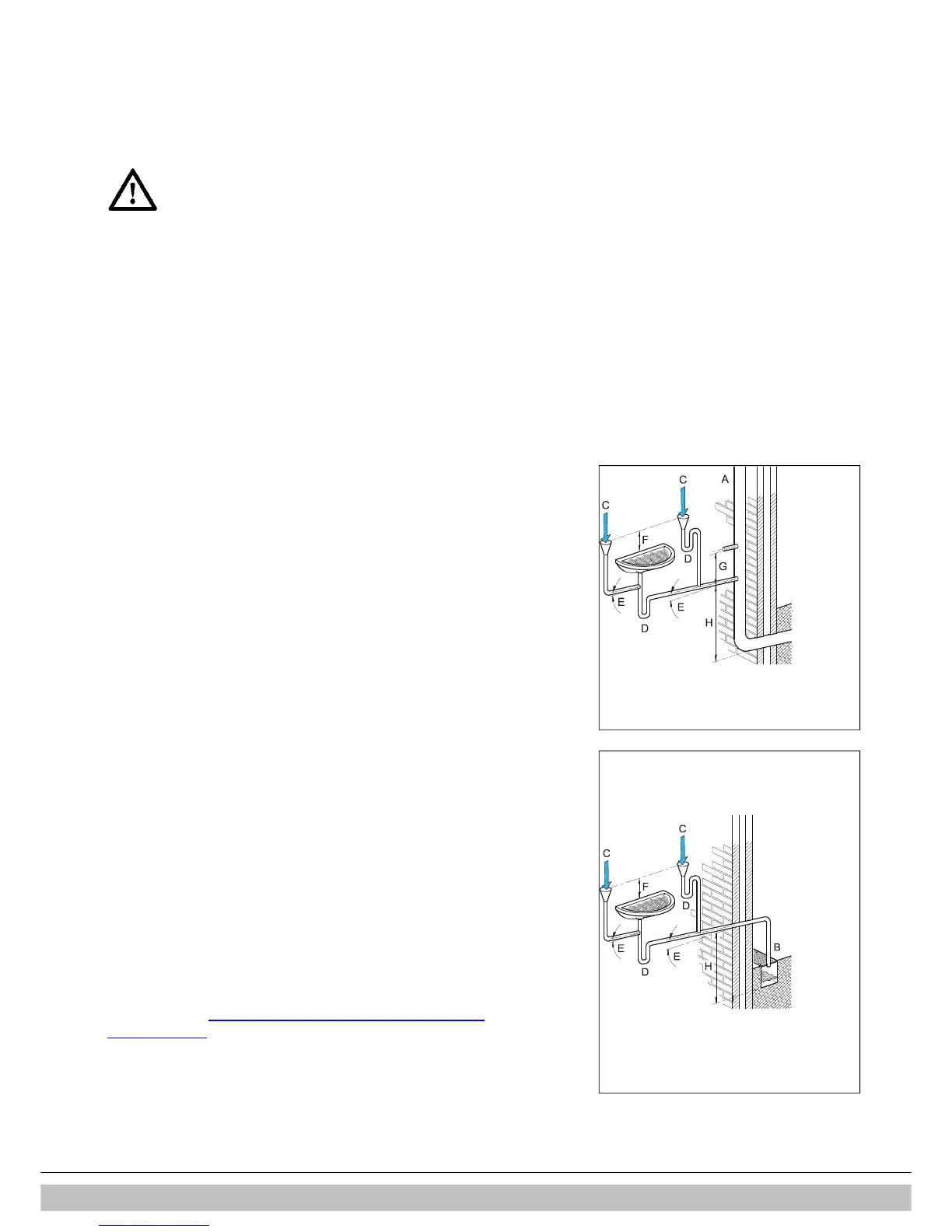

a. Internal stack pipe (see diagram)

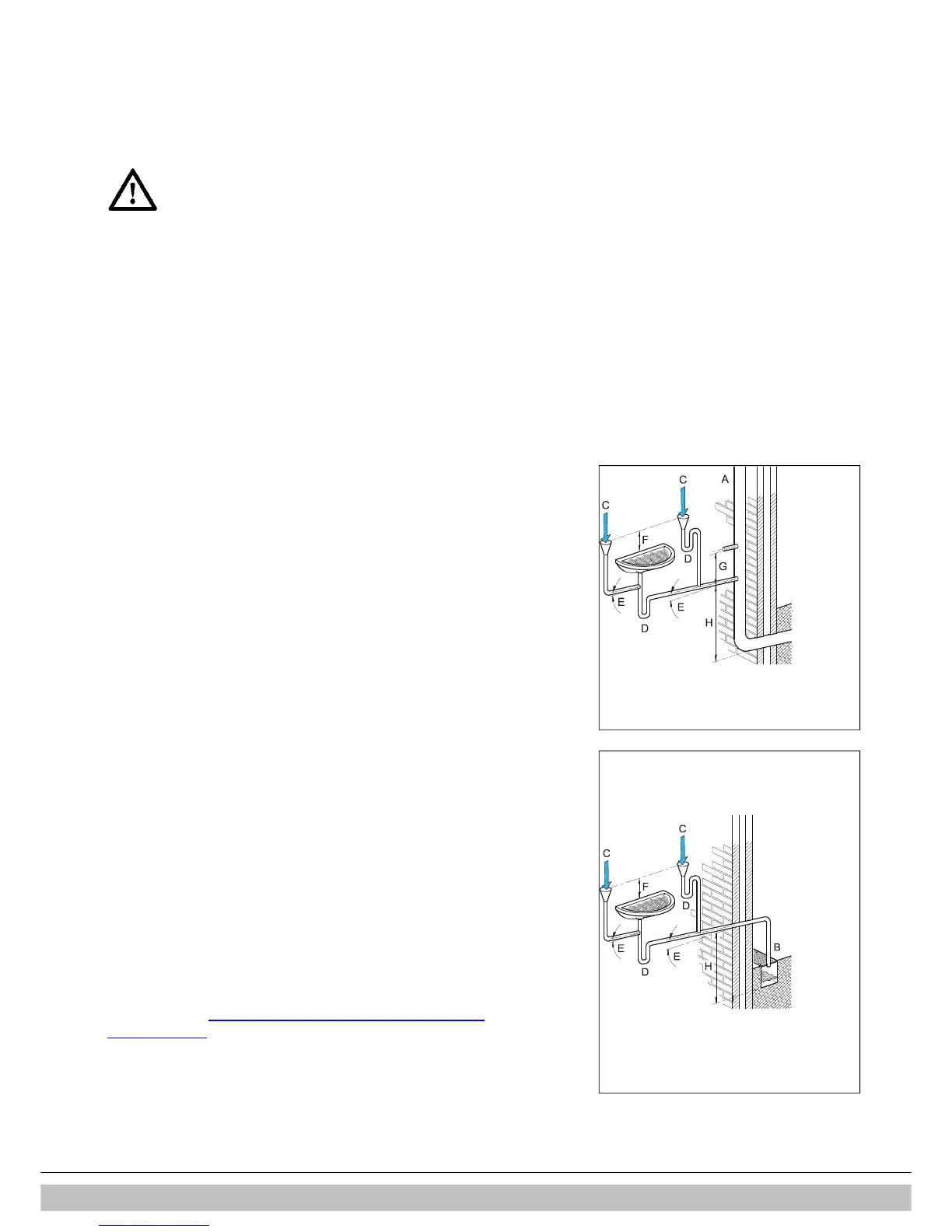

b. Gully

c. Condensate discharge from boiler

d. Servicable waste trap

e. 5 – 20 mm/meter

f. > 100 mm

g. > 110 mm

h. > 450 mm

If an externally-run condensate drainage pipe is used the following measures

should be adopted to prevent freezing:

- the pipe should be run internally as far as possible before going externally,

the pipe diameter should be increased to a minimum of 30mm ID (typically

32mm OD) before it passes though the wall;

- the external run should be kept as short as possible, taking the most vertical

route possible to the discharge point, with no horizontal sections in which

condensate might collect;

- the external pipe should be insulated using suitable waterproof and

weatherproof insulation (‘’Class O’' pipe insulation is suitable for this purpose);

- the use of fittings, elbows etc should be kept to a minimum ans any internal

‘’burrs’’ on cut pipework should be removed so that the internal pipe section is

as smoooth as possible.

For more information about preventive measures against freezing please visit

the HHIC website http://www.centralheating.co.uk/checklists/frozen-

condensate-pipes.

Loading...

Loading...