Intergas Heating Ltd 28

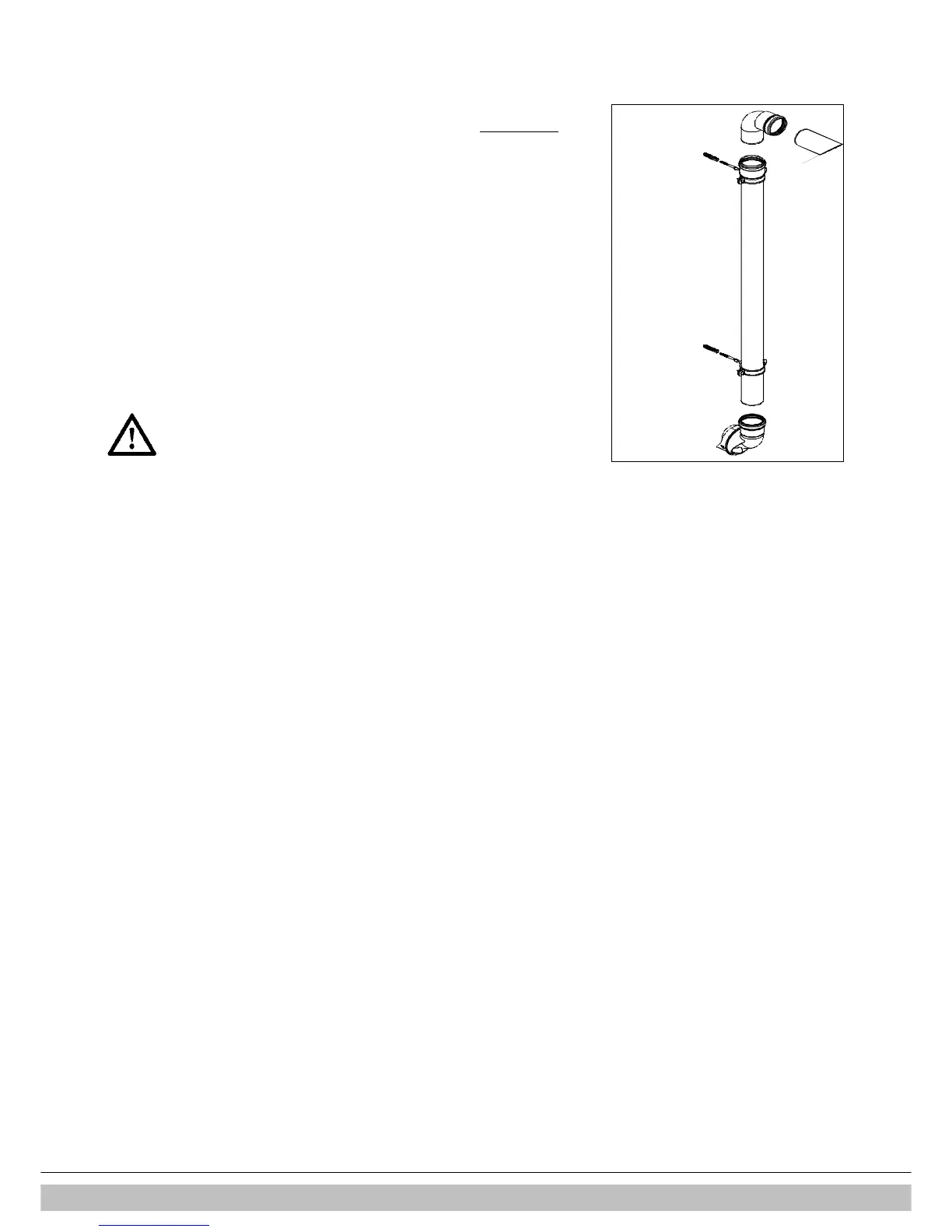

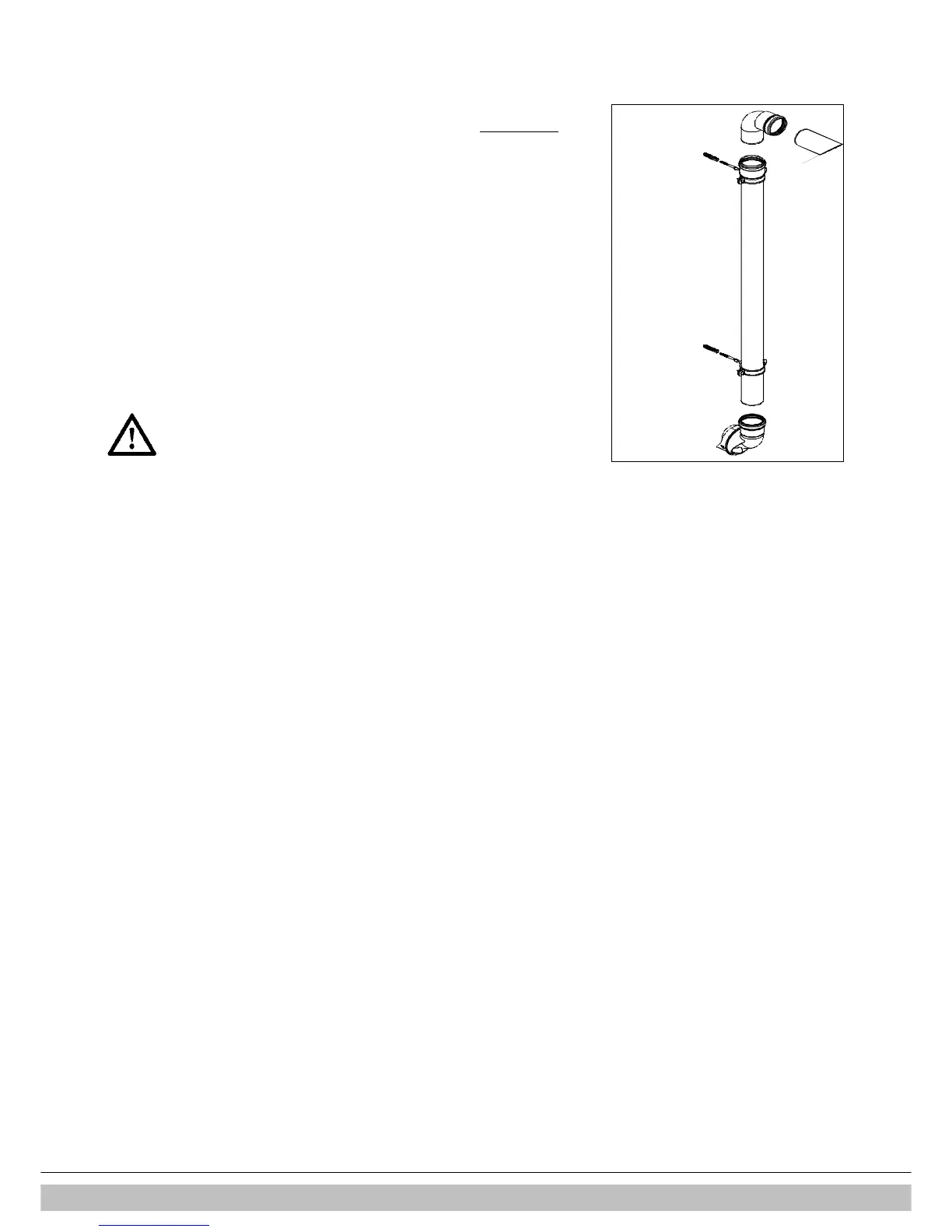

6.5.6 Plume management kit

The plume management kit comprises of a 710 mm horizontal section with elbow

to connect the 1m vertical condensing tube, which has a horizontal or vertical

terminal dependant on your requirements. The maximum length of horizontal flue

including the terminal but excluding the initial elbow from the boiler and 1 metre

vertical condensing tube is 7 metre.

Note

For each additional 90º elbow used the maximum flue length must be reduced by

1.5 metre, whilst the use of 2 x 45º bends warrants a reduction of 2 metre.

The horizontal part of the flue must be installed under a 3° fall towards the boiler (50

mm per metre) and must be supported with a minimum of 1 bracket at each meter

length. Best recommended position of the bracket is just before the joint.

6.5.7 Flues in voids

The flue system must be connected in accordance with the manufacturers instructions

BEFORE firing the boiler.

The term void includes ceiling voids, floor voids, purpose built enclosures ,service

risers, roof spaces or any other enclosure that will restrict access to inspect the flue.

To allow visual inspection, without reliance on devices such as endoscopes, cameras

and mirrors, inspection hatches must be provided along the entire length of the flue.

Hatches must be a minimum of 300mm x 300mm and positioned with the edge of the

inspection hatch to 1.5m of any joint and at changes of direction. Bends should be

viewable from both directions where the inspection hatch cannot be positioned at the

bend.

Where suitable access is not provided the appliance MUST NOT be commissioned and

must be disconnected from the gas supply.

Additionally the entire flue and all flue seals must be installed in accordance with the

requirements of BS5440:

1. Check condensate trap is filled with water and correctly connected to boiler.

2. All flue joints are correctly made, unstressed and adequately supported.

3. All parts of the flue can be visually inspected -ensure suitable access where flue is

positioned within voids-

• Sealing rings should only be moisturized with water before use. Do not use

soap or other detergents.

• When installing flues in voids make sure they are connected and

fixed correctly. If in an existing situation a visual inspection is not

possible the boiler must not be commissioned and remain

disconnected from the gas supply untill suitable access has been

realised.

• Make sure to follow the manufacturer’s instructions regarding

maximum length of the flue system, the appropriate flue material,

correct jointing methods and the maximum distance between flue

support.

• Ensure that all joints and seams are gastight and watertight.

• Ensure the flue system has a uniform gradient back to the boiler.

Loading...

Loading...