Intergas Heating Ltd

39

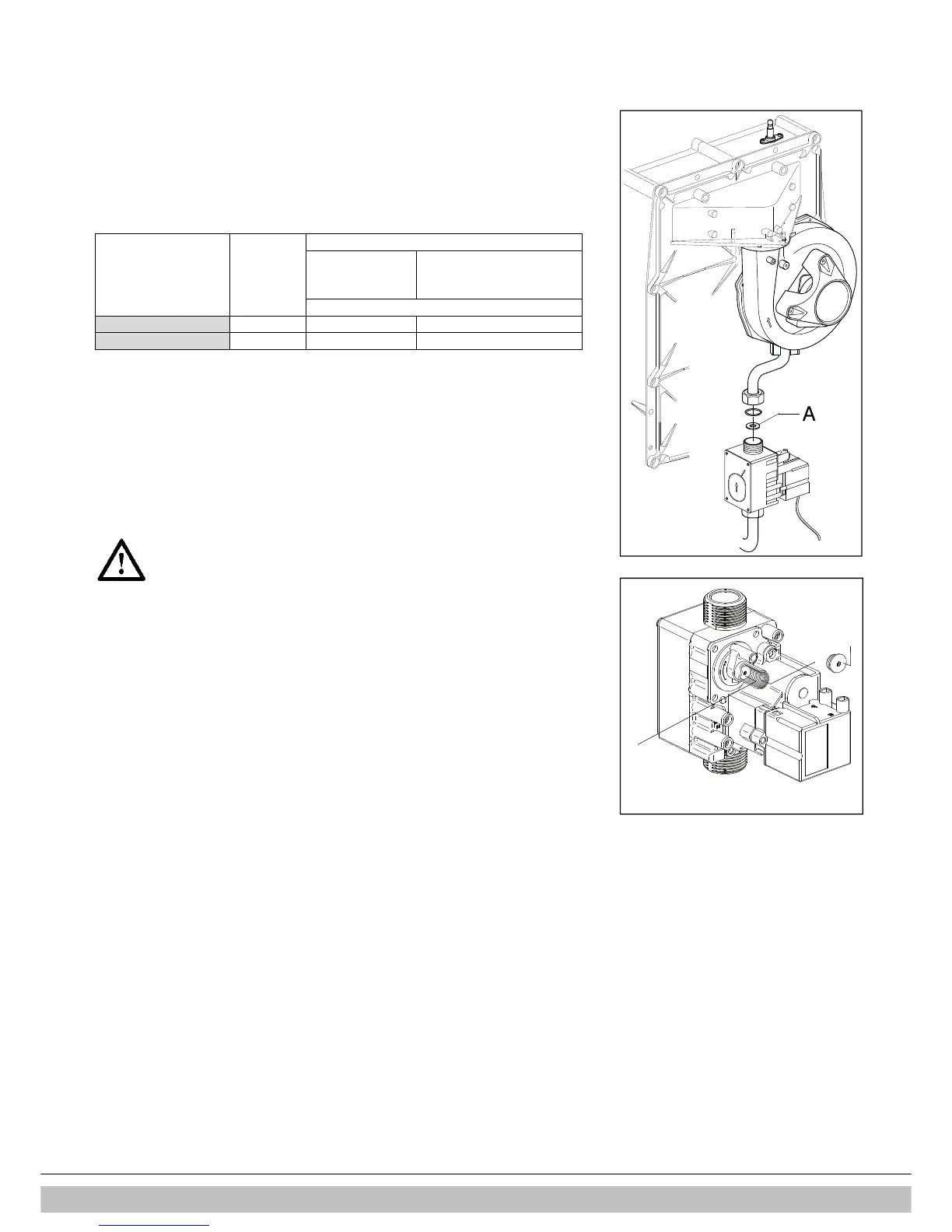

8.8 Gas-Air ratio control.

The gas air ration control of the boiler is set to the correct value in the factory and does not need to

be adjusted. The gas type of the boiler on which the boiler has been set is noted on the data plate.

The boiler is only to be used in combination with this gas type.

When necessary the boiler can be converted to another gas type using the appropriate conversion

set. See the table below for the correct gas ring.

Table 1, inserts and associated gas rings per boiler type.

Model

Insert

number

Gas category

Natural gas

20 mBar

Propane 3P

G31

30 mBar

Gas ring

Rapid 25 406 600 480

Rapid 32 362 655 525

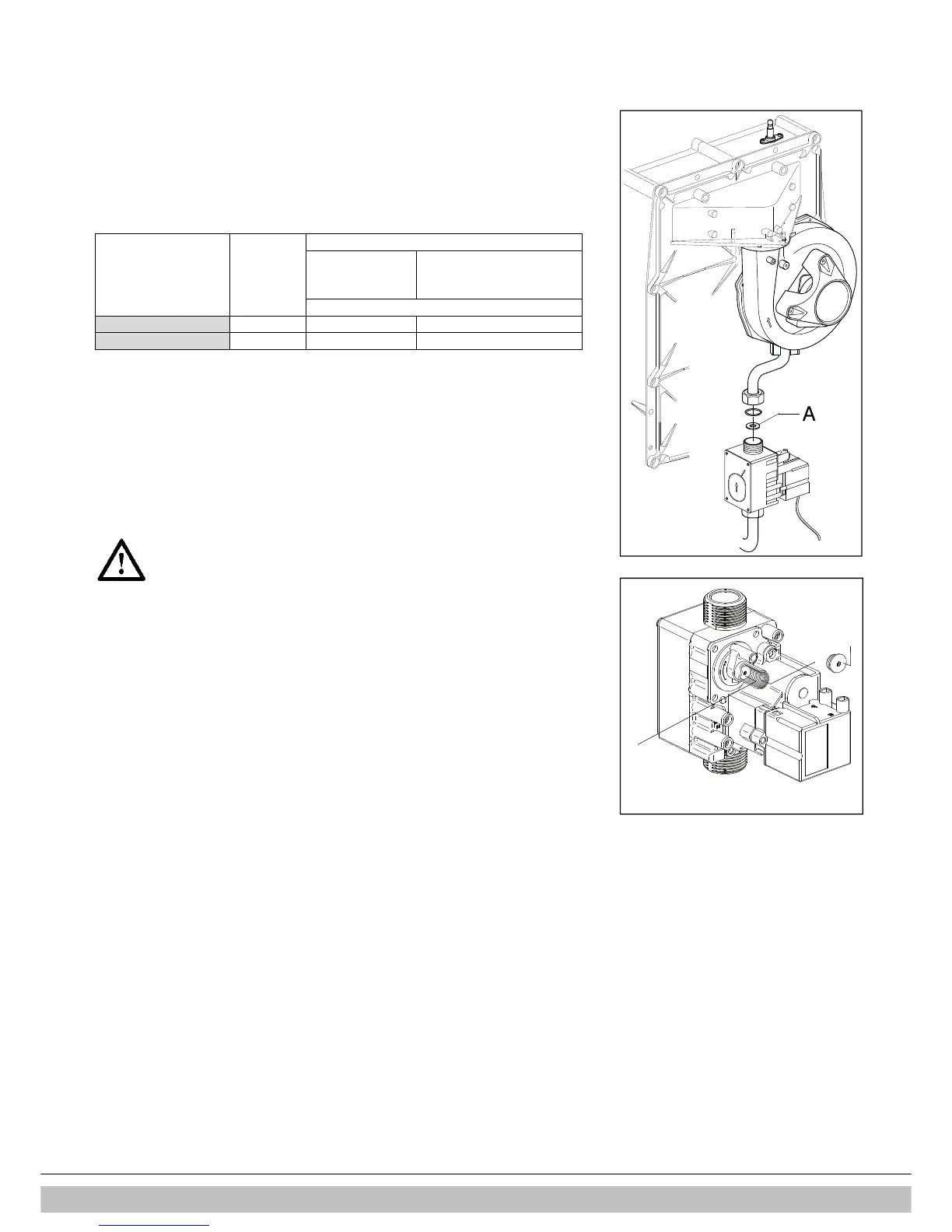

The correct setting of the Gas-Air ratio can be checked by measuring the flue gases using a

calibrated O

2

measuring device. The measurement must be performed first at maximum

power and thereafter on the minumum power.(see § 8.9.1 and § 8.9.2)

For reference reasons the tables below contain O

2

and CO

2

values.

When the CO

2

or O

2

value is incorrect only the setting on minumum power can be adjusted

(see § 8.9.3 ) by changing the setting of the gas valve.

Important

• During the CO

2

or O

2

check the front casing of the boiler needs to

be removed.

• The deviation of the O2 analyser must be restricted to +/- 0.3%

• A reliable measurement is only guaranteed when no extreme

vacuum in the flue pipe is present (i.e. draft due to hard wind).

• A deviation at maximum power can not be adjusted with the gas

valve setting. When the value measured at maximum power is

without the prescribed range the boiler has to be checked on gas

tightness and usage of the correct components, in particular the

gas ring and the fan.

• When replacing parts or converting the boiler to another gas type

the correct functioning of the gas air ration always has to be

checked.

Loading...

Loading...