4230 Flow Meter

Section 5 Maintenance and Service

5-13

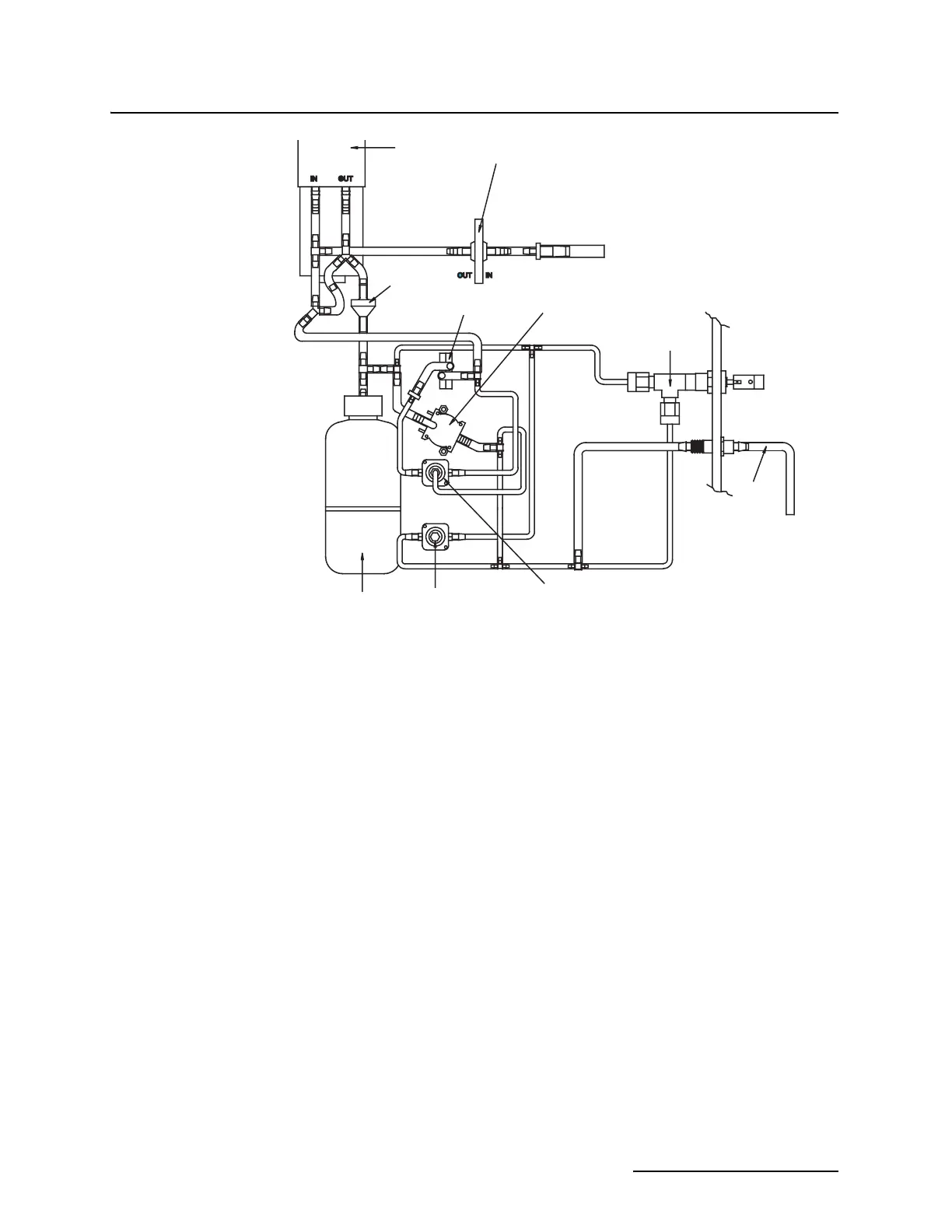

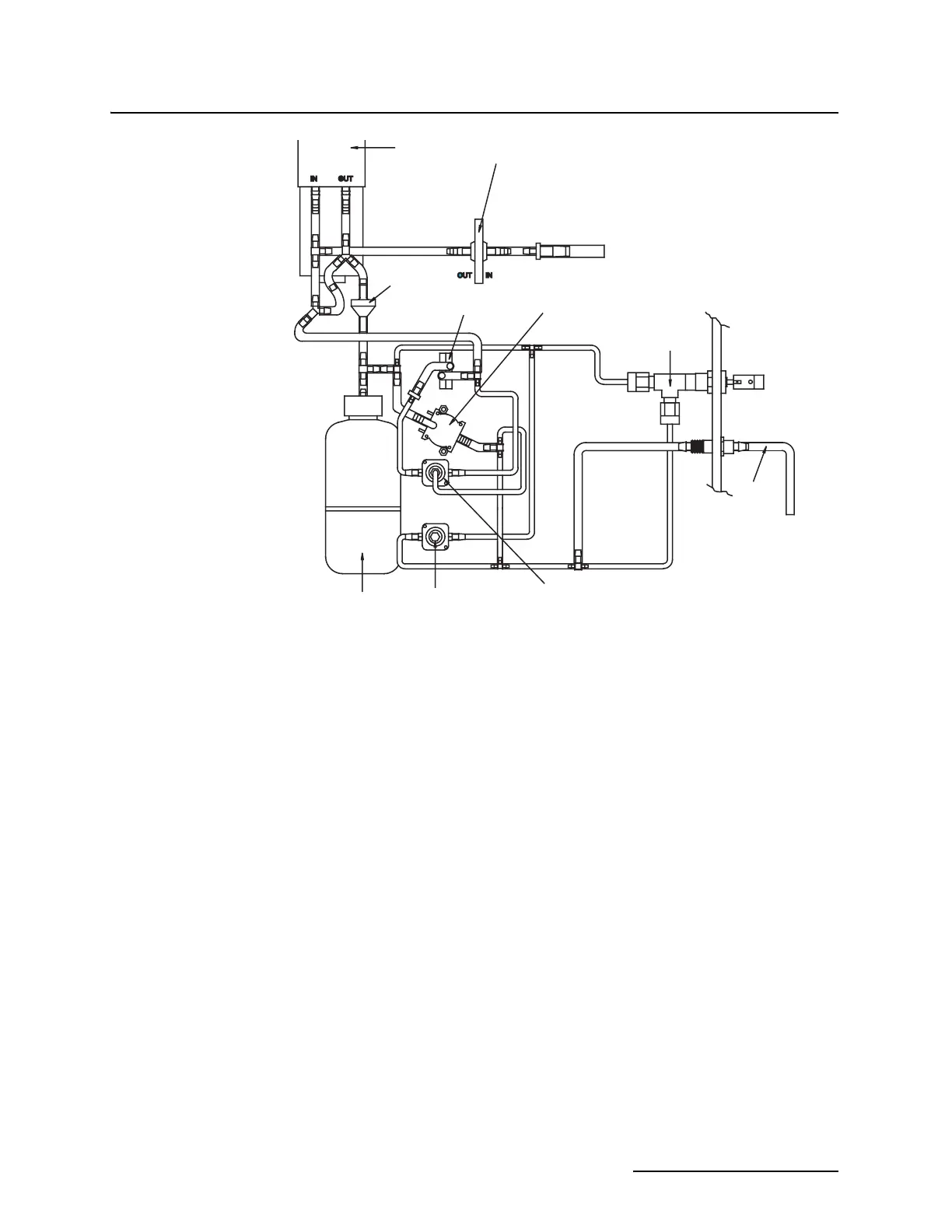

Figure 5-7 Schematic Diagram of the Bubbler System

While the purge valve pulses for short cycles to produce the

Super Bubble, it also opens to produce longer discharges of air at

intervals selected from the program, or you can operate it man-

ually through the use of the manual Purge switch on the keypad.

The purpose of the purge feature is to clear deposits from the

bubble line that build up over time and could eventually cause

clogging.

5.7.4 Pressure Transducer A temperature-compensated solid-state pressure transducer

measures the air pressure in the bubble line. The pressure is pro-

portional to the level. The pressure transducer connects to the

bubble line through the automatic drift compensation valve. The

reference side of this transducer vents to the outside of the case

through the external desiccator. The microprocessor converts the

output from this transducer into level and flow rate.

5.7.5 Automatic Drift

Compensation Valve

This valve, located directly across both ports of the pressure

transducer, turns on at power-up and from time to time after that

to tie the input and reference ports of the transducer together to

compensate for any drift that might occur. The software deter-

mines how often this valve turns on.

AIR PUMP

HYDROPHOBIC FILTER

CHECK VALVE

PRESSURE TRANSDUCER

BUBBLE RATE

ADJUST VALVE

BUBBLE

LINE

PURGE/SUPER

BUBBLE VALVE

AUTOMATIC DRIFT

COMPENSATION VALVE

AIR TANK

PRESSURE SENSOR

Loading...

Loading...