Do you have a question about the janitza UMG 509 and is the answer not in the manual?

Check the device for proper transport and storage, set-up, installation, operation and maintenance.

List of items included in the scope of delivery for the UMG 509.

List of optional accessories available for the UMG 509.

Intended application of the UMG 509 in building installations and distribution systems.

Overview of the general information and measurement capabilities of the UMG 509.

Description of how the UMG 509 measures and calculates effective values.

Explanation of how to program and access measured values using the UMG 509.

Details on using GridVis software for programming and data readout.

Guidance on integrating the UMG 509 into fixed and weatherproof switch panels.

Recommended vertical installation for adequate ventilation, with space requirements.

Details on the front panel layout and cut-out size for installation.

Information on Ethernet connection placement and clearance requirements.

Description of how the UMG 509 is mounted using clips in a switchboard.

Procedure for connecting the protective conductor to the UMG 509.

Requirements for connecting the UMG 509's supply voltage, including fuse protection.

Details on using the UMG 509 in TN and TT networks with earthed neutral conductors.

Suitability and limitations of using the UMG 509 in IT networks.

Suitability of voltage measurement inputs for networks with overvoltages.

Requirement for mains frequency and suitable network frequency range (40Hz-70Hz).

Correction of current direction via serial interfaces or directly on the device.

Safety guidelines for connecting and short-circuiting current transformer secondaries.

Using an ammeter in series with the UMG 509 for current measurement.

Programming residual current transformer ratios using GridVis software.

Configuration of termination resistors using the S1 DIP switch.

Details on connecting a Profibus connector and its termination resistors.

Explanation of the functions assigned to each of the six function keys.

How to scroll between the main measured value displays using keys 2 and 5.

How to select by-values of a measured value display using keys 3 and 4.

Steps to scroll, select, and display transient data in graphical format.

Procedure to navigate and display detected events, including graphical representation.

Steps for connecting the supply voltage and initial device display.

Procedure to set the device language via the configuration menu.

Selecting address assignment type for the Ethernet interface.

Automatic IP address assignment via DHCP server.

Specifying the protocol, device address, and baud rate for RS485 interface.

Setting a unique device address within the bus structure.

Selecting the communication speed for the RS485 interface.

Assigning current transformer ratios for baseline and supporting measurements.

Defining the rated current value for overcurrent and transient detection.

Defining rated voltage for transients, events, and graphics scaling.

Activating or deactivating failure monitoring for residual current inputs.

Transient detection based on difference between neighboring sampled points.

Adjusting transient monitoring settings across phases L1, L2, L3, and L4.

Setting voltage drop as a percentage of rated voltage.

Setting voltage swell as a percentage of rated voltage.

Setting rapid current increase as a percentage of nominal current.

How the UMG 509 automatically determines mains frequency.

Procedure to clear all energy meters simultaneously.

Restoring factory default settings and restarting the device.

Configuring the backlight brightness for device operation.

Setting the time until the brightness switches to standby level.

Setting the brightness level when the device enters standby mode.

Activating the screen saver to prevent LCD image burn-in.

Automatically showing measured value displays one after another.

Setting the time for automatic switching to the next measured value display.

Activating purchasable functions and displaying Jasic program statuses.

Connecting the supply voltage and the initial device display.

Connecting measured voltages and verifying displayed values.

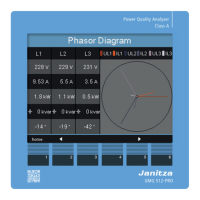

Checking the direction of the rotating field voltage in the measured value display.

Continuous monitoring of the connection to the residual current transformer.

List of Modbus functions available for master operation.

List of Modbus functions available for slave operation.

Data exchange between UMG and PLC using preconfigured Profibus profiles.

Description of the GSD file for Profibus characteristics of the UMG 509.

Scaling and conversion of system and global variables into various formats.

Setting the pulse interval, which depends on measured power and can take hours.

Information on repair and calibration services provided by the manufacturer.

Instructions for cleaning the front film with a soft cloth and mild cleaning agent.

Guidelines for recycling the UMG 509 as electronic scrap.

Contact information and required details for technical support.

Details on factory calibration and the necessity of recalibration.

Recommendation for device recalibration every 5 years.

Basic technical specifications including weight, dimensions, and battery type.

Information on free fall, temperature, and relative humidity for transport/storage.

Operational environment specifications: temperature, humidity, altitude, pollution degree.

| Device Type | Power Quality Analyzer |

|---|---|

| Frequency Range | 45 - 65 Hz |

| Power Measurement | Active, reactive, apparent power |

| Display | Graphical LCD |

| Operating Temperature | -10°C to +55°C |

| Measurement Category | CAT III 600V |

| Current Measurement | Via external current transformers (1A or 5A) |

| Energy Measurement | Active, reactive, apparent energy |

| Harmonics Analysis | Up to the 50th harmonic |

| Communication Interfaces | Ethernet, RS-485 |

| Data Storage | Internal Memory |

| Storage Temperature | -20°C to +70°C |

| Accuracy | Class 0.5 for active energy, Class 1 for voltage and current |

| Protocols | Modbus TCP, Modbus RTU |

Loading...

Loading...