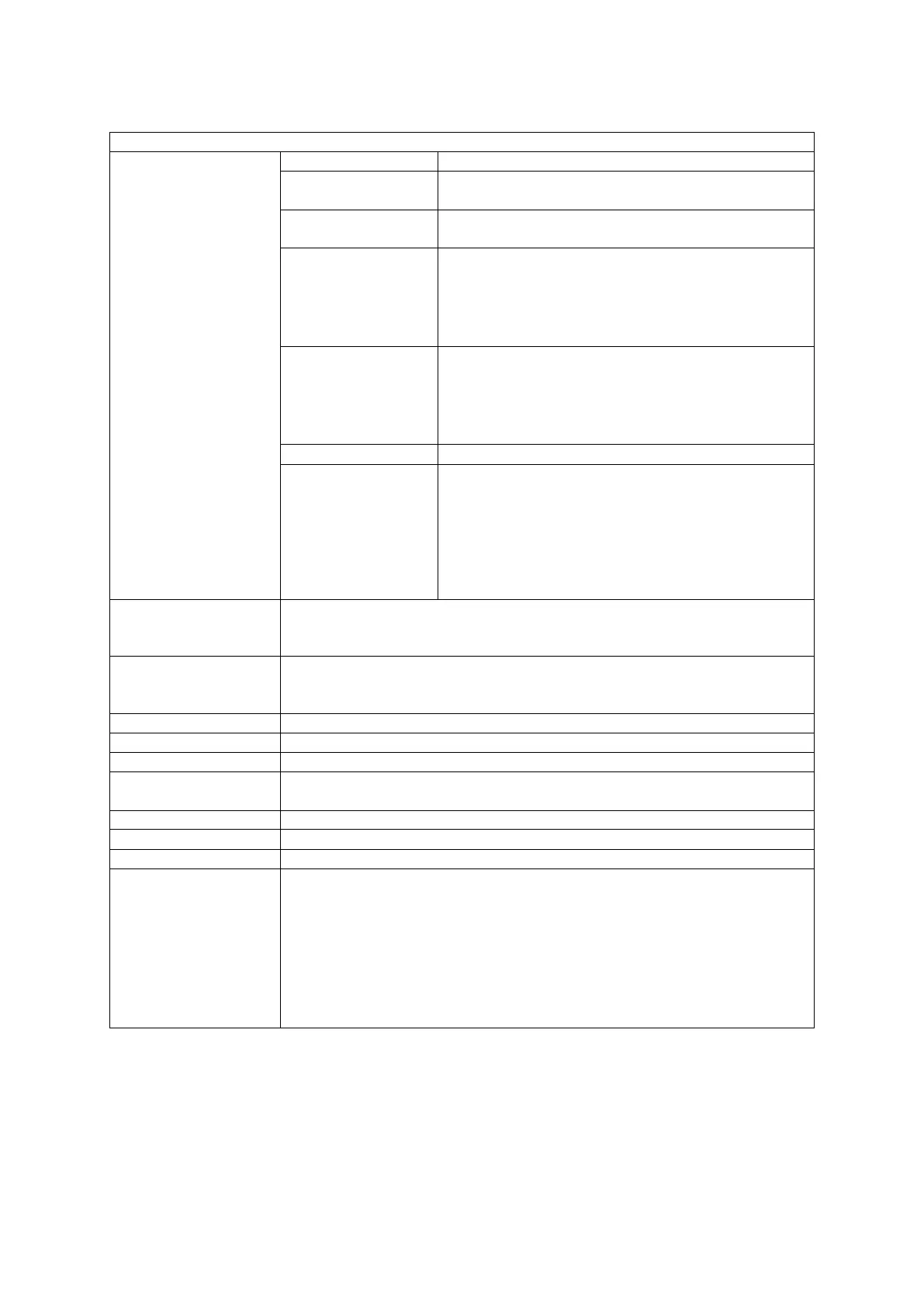

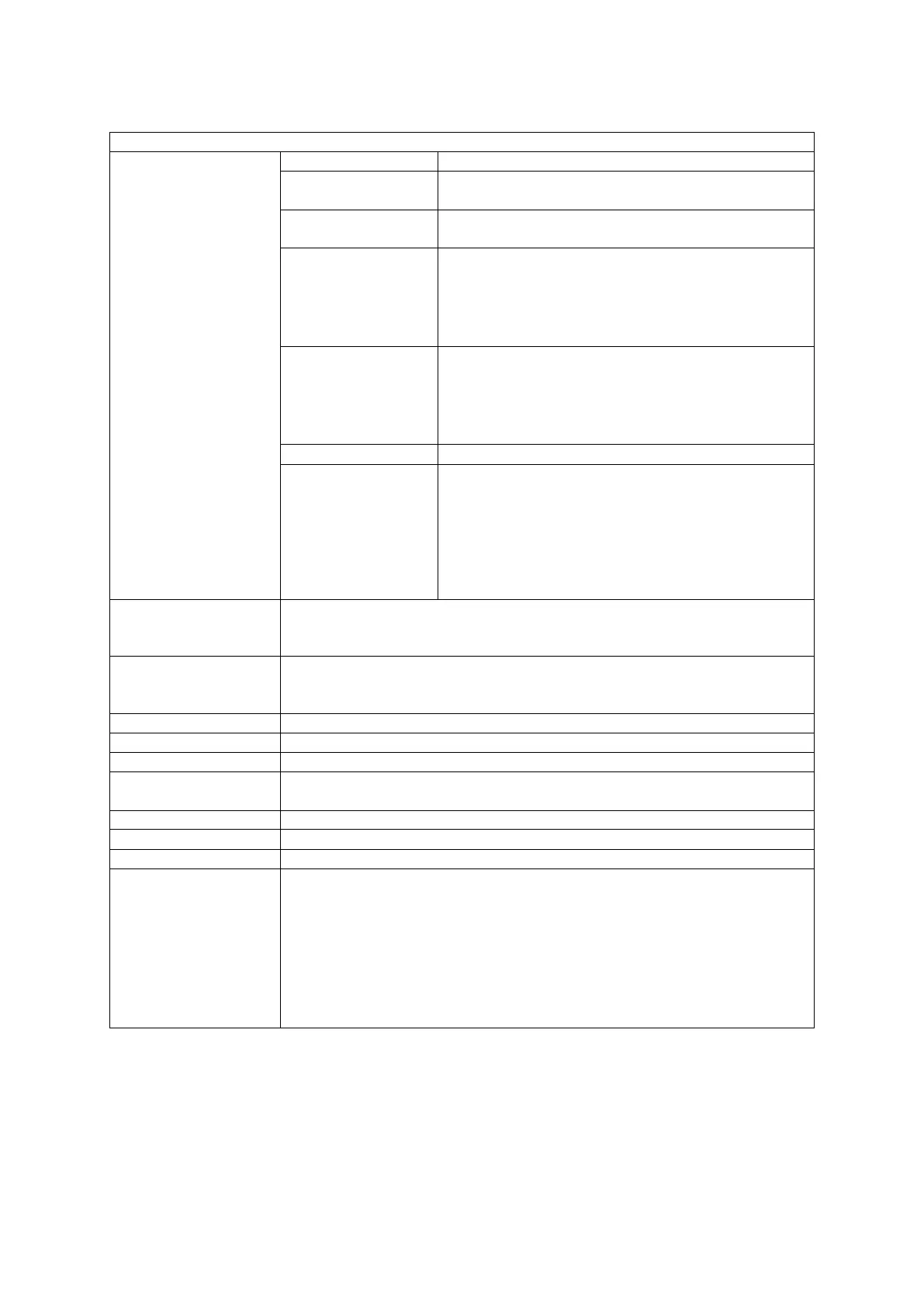

External Input/Output

RS-232C. External device control.

RS-232C. External device control.

RS-232C. External device control.

MEMORY

• Read C & T data

• Save C & T data

• Update the system software version

• Update the model setting data

LAN

Dedicated for communicating with the PC software

JR C-Points II.

• Send and receive C & T data

• Control the robot with control commands

• Update the system software version

Teaching pendant (optional) dedicated connector.

SWITCH BOX

(Switchbox

specifications only)

• Switchbox dedicated connector.

• If this is a switchbox with a switch for changing

modes (optional), you can change modes via the

key switch.

•

If this is a switchbox with an optional switch

attached, you can set an operation (dispenser tip

purging etc.) to the optional switch.

Power Source

1) 90 – 125/180 – 240V, 50/60Hz no outlet models

2) 180 – 240V, 50/60Hz outlet models

3) 90 – 125V, 50/60Hz outlet models

2) 1.1 – 0.8A

Not exceeding 1000m above sea level

Operating Ambient

Temperature

0 – 40deg

20 – 90% (no condensation)

-10 – +50deg and not exceeding 95% humidity

• Operation manuals (CD-ROM)/booklet (Setup)

• For Your Safety

• Timing belt tension adjustment screws (hex socket bolts M4x14): 2

• Cable tie fixings (adhesive is included on the robot rear): 4

• Cable ties: 5

• Robot cable grease: 10g

• Printed circuit board FB cover: 1 (Fieldbus spec. robots)

• Lockscrews (± binding head screw M4x6): 2 (Fieldbus spec. robots)

*

1

Point data shares its memory domain with job data, additional function data, PLC program data etc.,

and therefore as this data increases, you may not be able to create the maximum number of points.

*

2

To use an inte rnal powe r s up pl y, an I/O internal power supply (optional) is required.

128

Loading...

Loading...