19

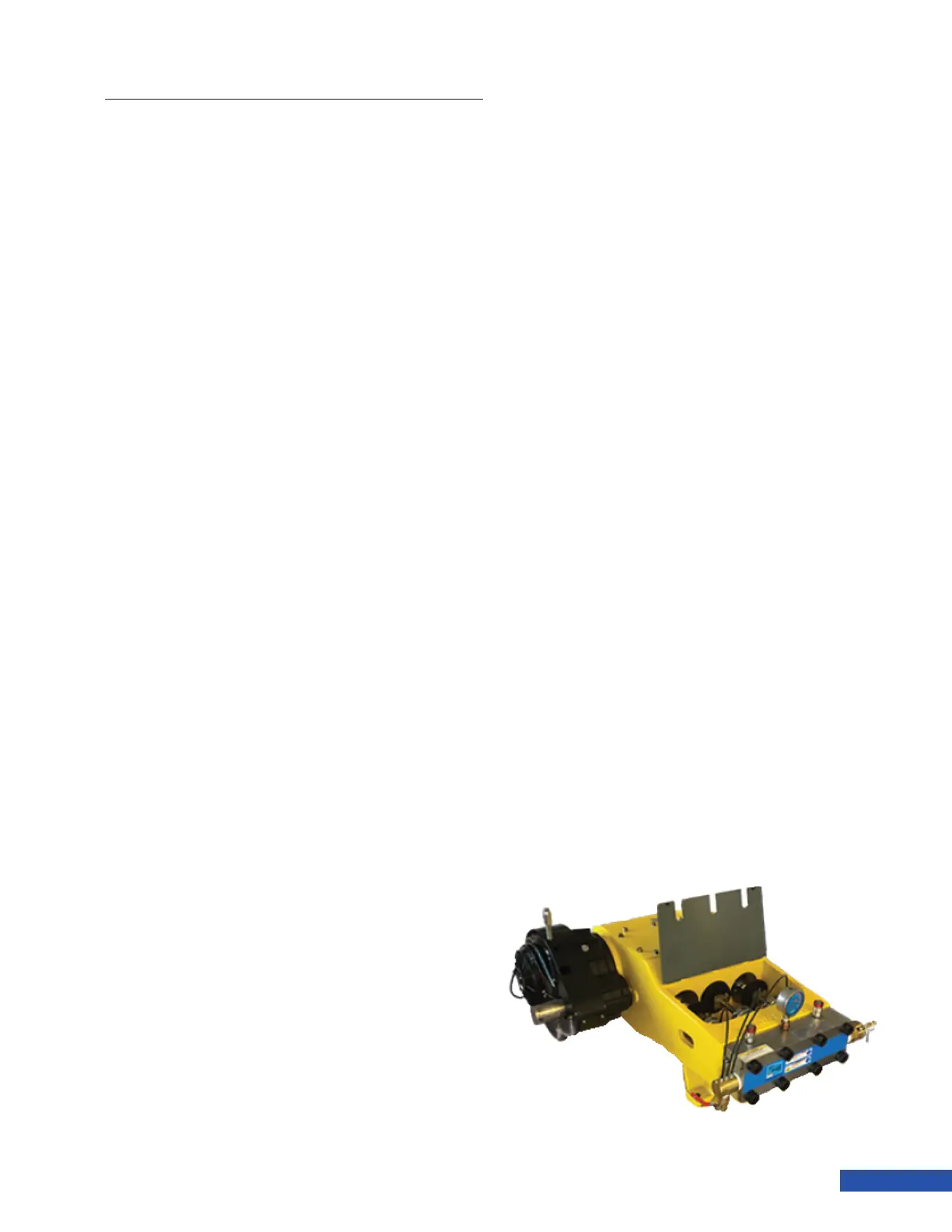

X-Series Waterblast Unit

Jetstream 3000/3600/4200

Bareshaft Pump Installation

Guidelines

Models

The Jetstream UNx bareshaft pump is avail-

able in three horsepower ranges and three

pressure ranges – 15,000 psi, 20,000 psi, or

40,000 psi and can be supplied with an op-

tional geardrive. The geardrive is available

in four different gear ratios to support die-

sel engine or electric motor input speeds.

Both styles can be supplied left hand drive

or right hand drive (as viewed from FE) and

the geardrive model’s input shaft can also

be clocked to ve different locations. The

geardrive unit requires inline drive with

exible coupling***. The standard unit can

be inline or belt driven via pulleys exerting a

side load on the crank- shaft. All Jetstream

powerends have a preferred rotation direction

(top of crankshaft towards the uid end) that

is marked on the casting. However reverse

rotation operation is allowed with the addition

of optional reverse rotation oil scrapers. The

geardrive requires a clockwise input rotation

direction.

3000 series 150 hp max 600 rpm max

3600 series 175 hp max 550 rpm max

4200 series 325 hp max 518 rpm max

Water Supply

The 15K and 20K versions can be gravity fed

(water level 3’ minimum above the manifold

suction inlet). The 40K version requires 40 psi

minimum supply pressure at full pump speed

to operate. All uid ends have a maximum

inlet supply pressure of 75 psi.****

The supply water should be clean and cold. The

maximum allowed inlet water temperature

is 125°F. Ideally the water should be ltered

to 25 micron (3 micron for 40K) and 40-80°F

for maximum packing life. Severly reduced

packing life will be encountered with warmer

water. The inlet supply hose should be 3” ID if

gravity fed and 2” ID if pressure fed. Jetstream

recommends oileld suction hose as it has

proven to be durable with a relatively small

bend radius. The hose should be as short and

straight as possible with no additional ttings

(elbows) - especially important with gravity

fed setup. If bends are required it is best to

bend the hose without the use of elbows.

The plunger packing is lubricated with the

supply water and is not adjustable on nor-

mal gravity fed 15K/20K systems. On 40K and

pressure fed systems, the lube harness needs

to be equipped with needle valves to allow

adjustment of the lube water ow. The cooling

water should exit the rear of the gland nuts

with a steady stream (more than a drip) but

not enough to be splashed onto the pony rod

during operation.

Pulsation

Positive displacement pumps create pulsa-

tion in the high pressure discharge line. For

this reason, it is extremely important to utilize

exible hoses (ie rubber, thermoplastic) in lieu

of rigid piping to minimize water hammer and

vibration. If rigid piping is necessary, it should

not be installed at the pump discharge. A 25’

or 50’ section of hose should be installed at

the pump discharge. This length can be coiled

and hung for space savings. A high pressure

pulsation damper may be benecial in some

cases. Short on/off cycles at high pressure will

create the largest spikes of pressure and re-

quire care to damp- en. Flow controls or other

means to slow the abrupt change of pressure

will smooth these pulsations.

Loading...

Loading...