27

X-Series Waterblast Unit

11. Reduce the discharge ow by fully open-

ing the bypass valve.

12. With the engine at idle speed, disengage

the clutch.

13. The nozzles can now be installed on the

discharge device(s).

14. Before waterblasting, adjust the lubrica-

tion line needle valves, if equipped. Refer

to “Checknig the Water Lubrication Sys-

tem” on page “Checking the Water Lubri-

cation System” on page 27 .

Checking the Water Lubrication

System

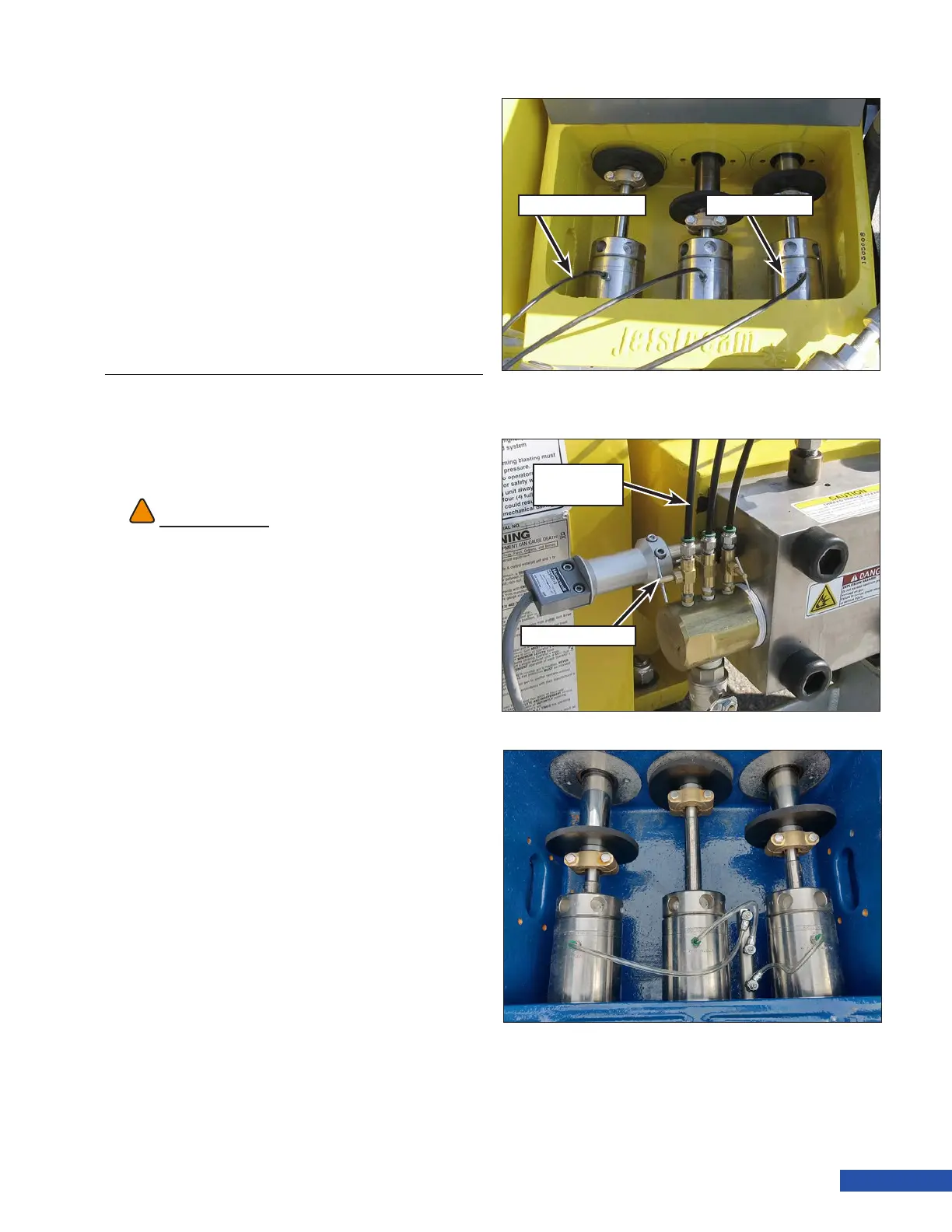

1. Lift the rod box cover to view the water

lubrication system.

2. Look into the rod box and verify that lu-

brication water is owing from the back

of the gland nut at the plunger/gland nut

intersection. The ow should be a small

stream but should not splash onto the

pony rods. (Figure 35).

3. Next, check the stufng box temperature

by very carefully placing your nger tips

on the top of the stufng box. The temper-

ature should be cool to warm but still cool

enough that you can keep your ngers on

it for 10 seconds.

If there is no water ow, or the tempera-

ture is too hot, or if steam is visible, the

needle valves need to be adjusted.

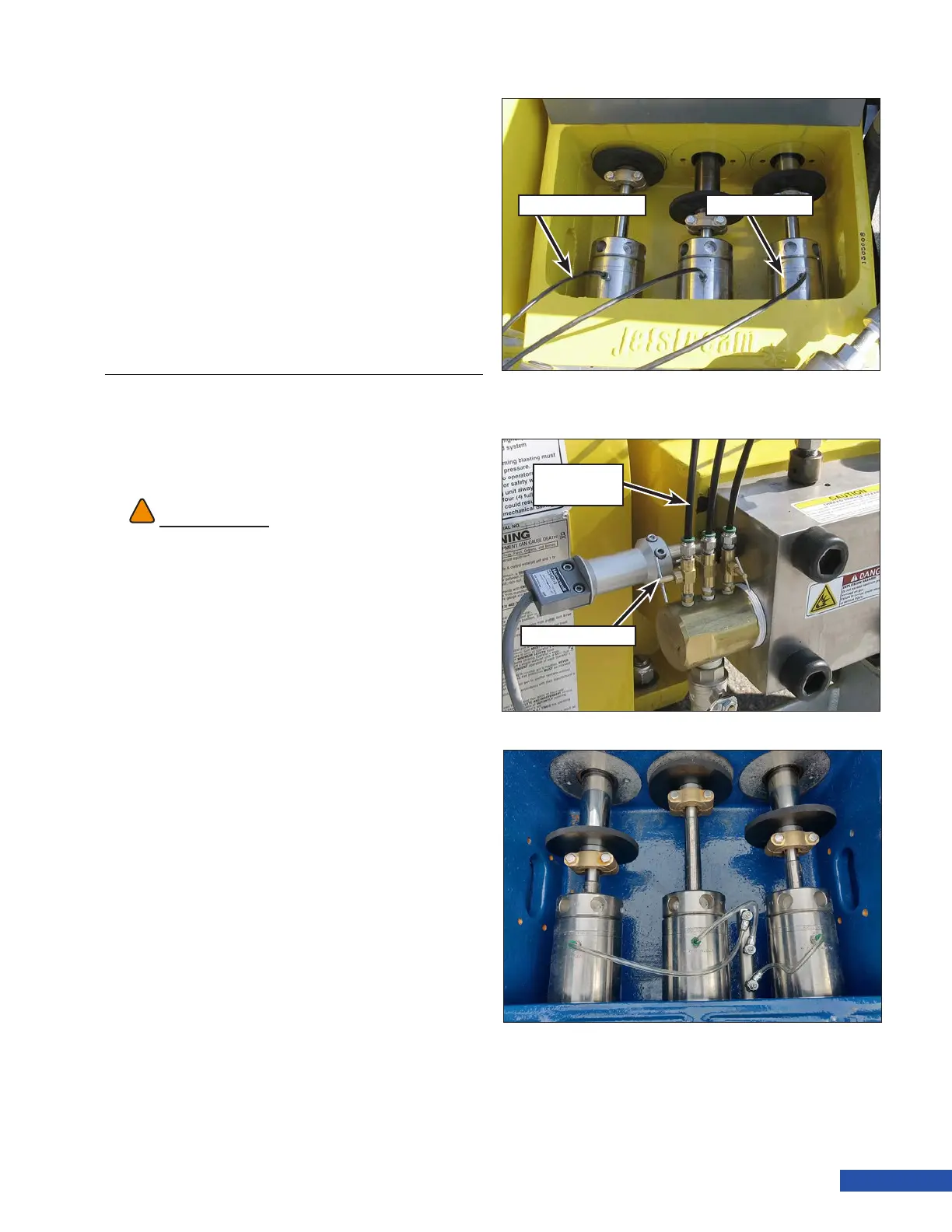

4. Adjust the needle valves (Figure 36)

(needle valves are only included on pres-

sure fed setups. Gravity fed units will not

utilize needle valves) to increase the

water ow. Excessive splashing may

occur, which could cause water to be

drawn into the power end, contaminating

the oil. Adjust the needle valves to pre-

vent excessive lubrication water ow.

Re-check the lubrication water ow

periodically during operation.

WARNING

!!

There are moving parts inside the rod box that can

cause serious injury. Use extreme caution. Keep all

tools out of the rod box while the pump is running.

Lubrication Line

Needle

Valve

Lubrication Line Stuffing Box

Figure 35: Checking Lubrication.

Lubrication

Line

Needle Valve

Figure 36: Needle Valve Adjustment (40K).

Figure 37: 5200 Series Water Lubrication System.

Loading...

Loading...