88

Operation Manual

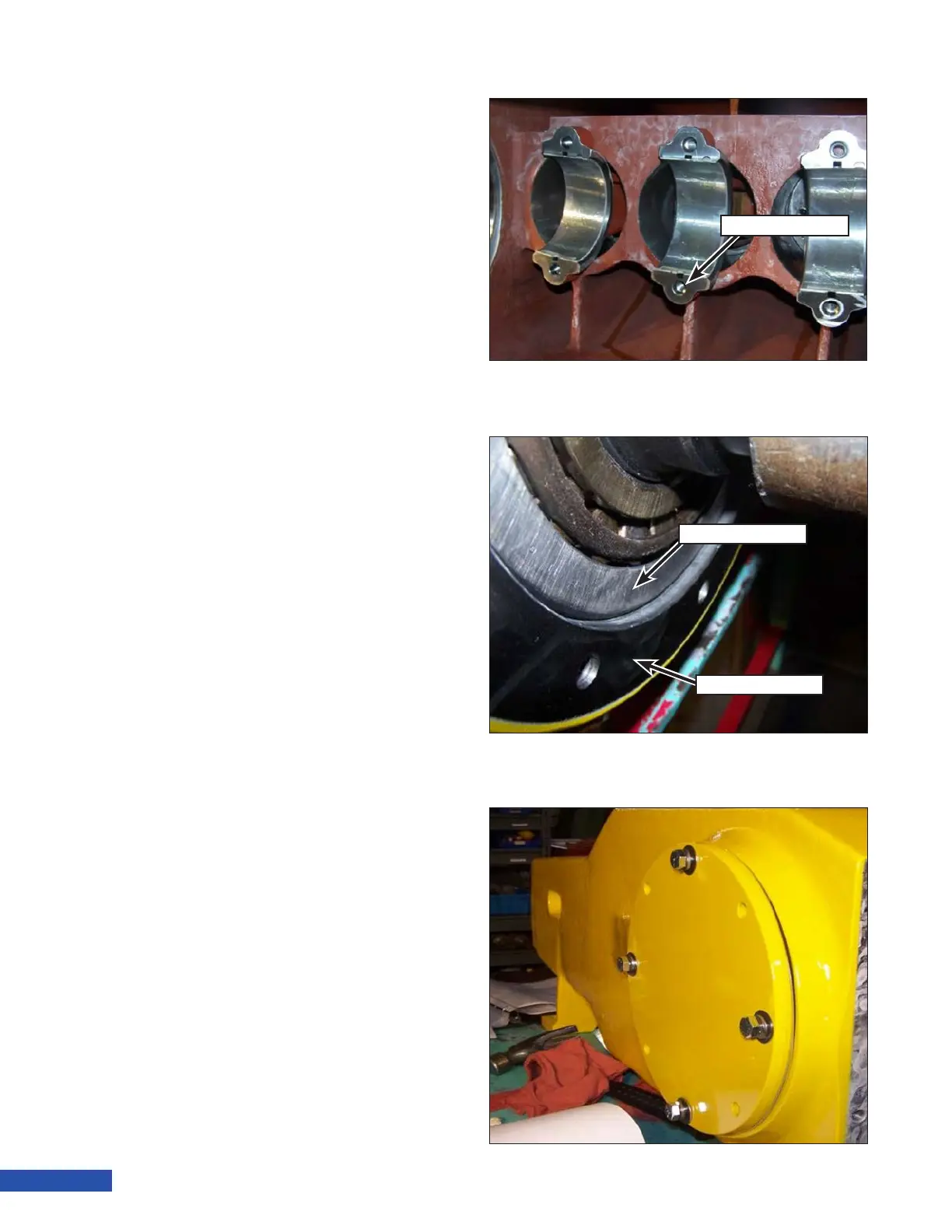

7. Place the three crosshead/connecting rod

assemblies into place (Figure 184). Allow

clearance for the crankshaft by pushing

them towards the uid end.

8. Install two threaded rods (1 in.-8NC x 8 in.)

into the ends of the crankshaft to aid in

installation.

9. Using two people, lift the crankshaft into

the power frame. The weight of the crank-

shaft is approximately:

• 3000 Series: 125 lb. (57 kg)

• 3600/4200 Series: 325 lb. (147 kg)

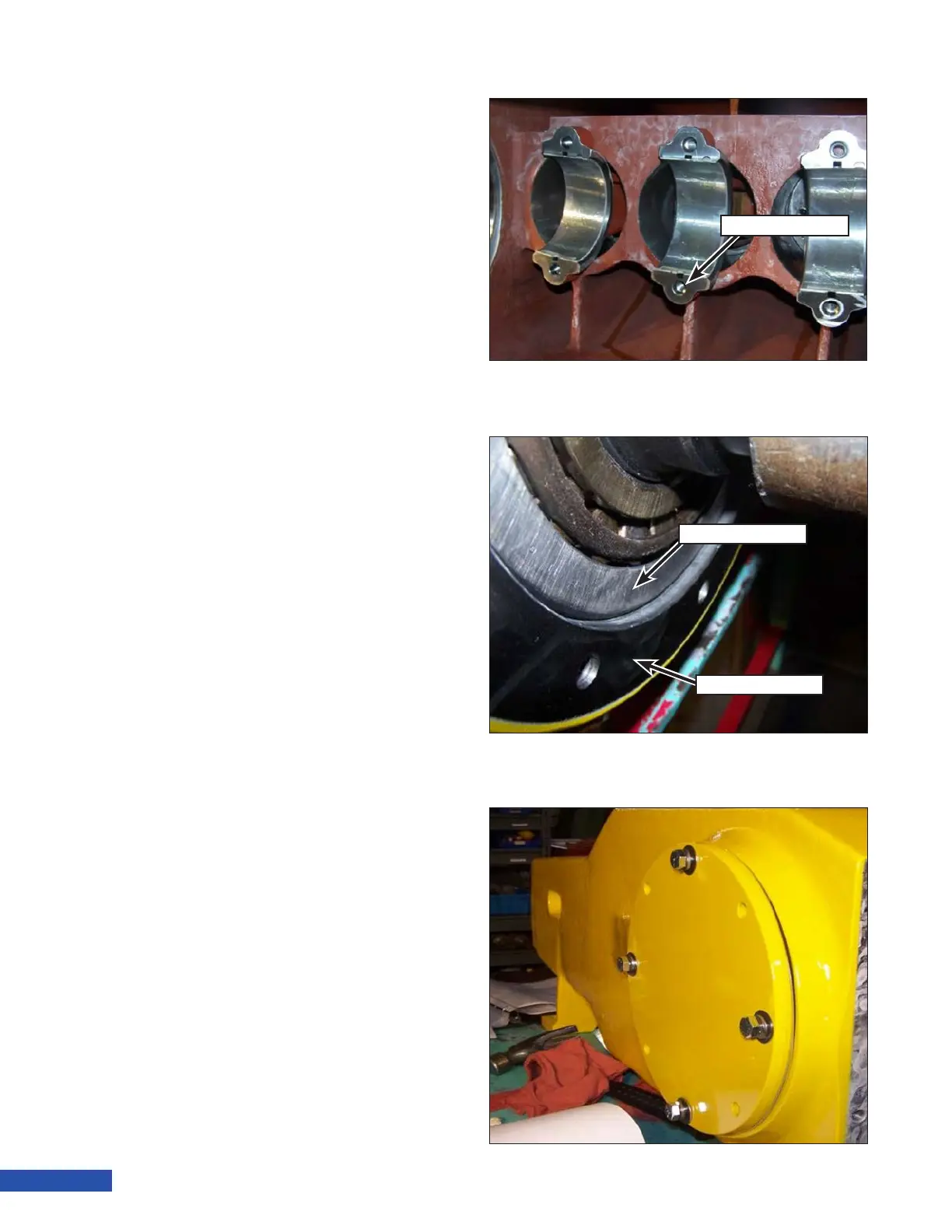

10. Using a wood block and a hammer, hit

either end of the crankshaft to seat it in

the bearing bore. Ensure the outer bear-

ing race (Figure 185) is inside the power

frame case.

11. Tap in the bearing race on the opposite

end of the crankshaft if not already in-

stalled.

12. Install a new oil seal and O-ring onto the

inboard side plate. Install the outboard

and inboard side plates with the original

shim packs. Ensure the thickness of each

shim pack is equal on both ends. Install

four equally spaced side plate capscrews

and tighten to 50 ft.lb (68 N·m) (Figure

186).

Figure 184: Connecting Rod Installation.

Connecting Rod

Bearing Race

Power Frame

Figure 185: Crankshaft Seating.

Figure 186: Side Plate Installation.

Loading...

Loading...