39

X-Series Waterblast Unit

WATER TANK AND FILTRATION

Water Quality Requirements

The quality of water that is supplied to your

Jetstream pump can have a direct impact

on performance. Items like dissolved solids

and pH values out of the allowable range can,

either by themselves, or together with other

properties of the water, lead to premature fail-

ure (such as cracking) of pump components

and related accessories.

Suspended gasses (tiny bubbles) in the water

can also lead to premature component failure.

These gases can sometimes be detected visu-

ally by inspecting the water in the inlet tank

for tiny bubbles or a milky appearance.

As part of the installation and or operat-

ing procedures of this pump, an expert that

specializes in water quality must perform a

water quality test. If your water is found to

exceed any of the allowable measurements in

the chart below, consult a specialist in water

purication and conditioning.

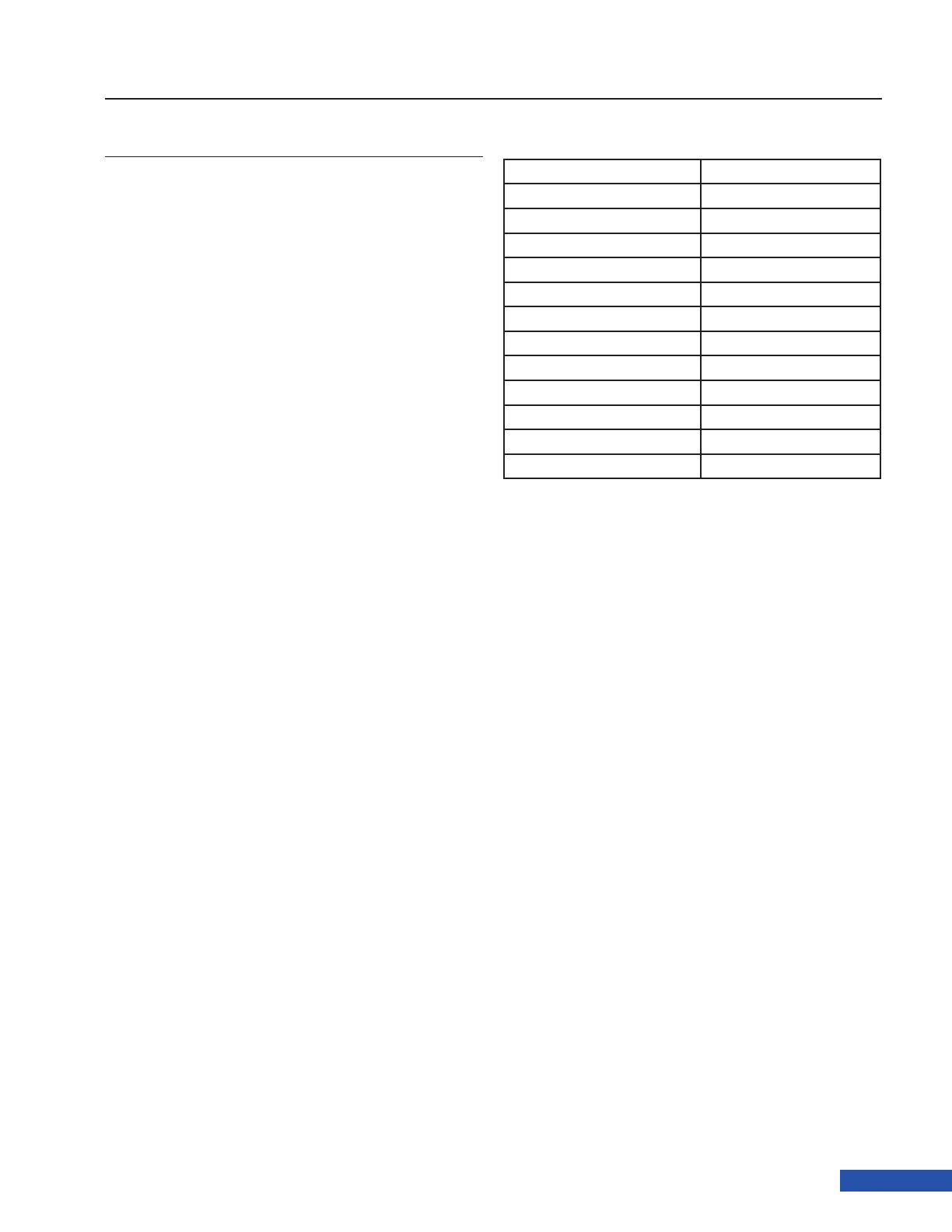

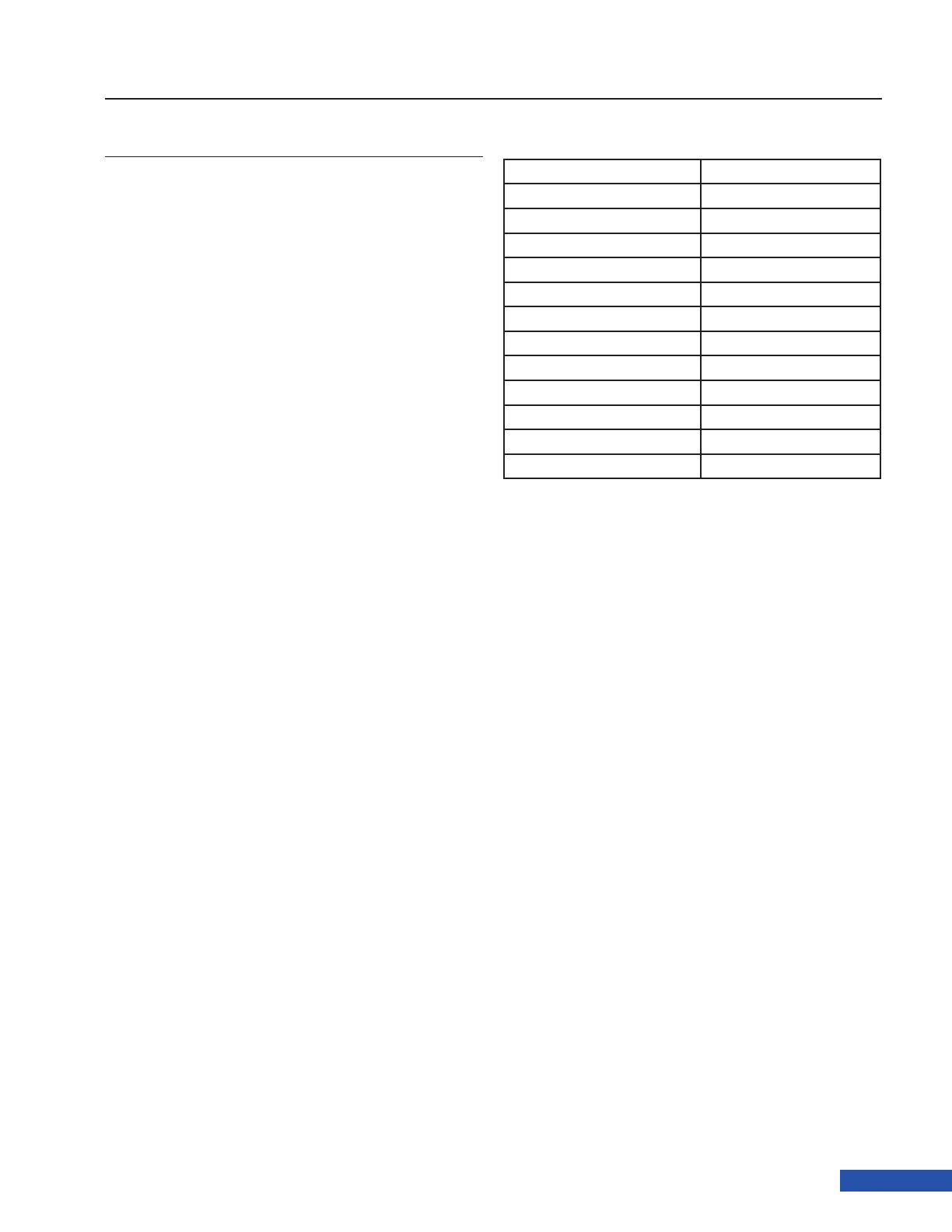

Recommended water quality levels:

Substance Maximum Allowed (mg/L)

Silica 1.0

Calcium 0.5

Magnesium 0.5

Iron 0.1

Manganese 0.1

Chloride 5.0

Sulfate 25.0

Nitrate 25.0

Carbon Dioxide 0

Total Dissolved Solids 50.0

pH 6.8 – 7.5

Specic Conductivity 50 micro-mhos/cm

Note: Boiler water additives with either

ammonia or amines are not

allowed.

Note: If water that has been treated by

either reverse osmosis or deion-

ization is to be used in your pump,

it is important that it does not

have a total dissolved solids (TDS)

reading of less than 0.5 ppm.

Water with a TDS reading of 0.5

ppm or less has been known to

attack carbide components such

as plungers and back-up rings.

Loading...

Loading...