41

X-Series Waterblast Unit

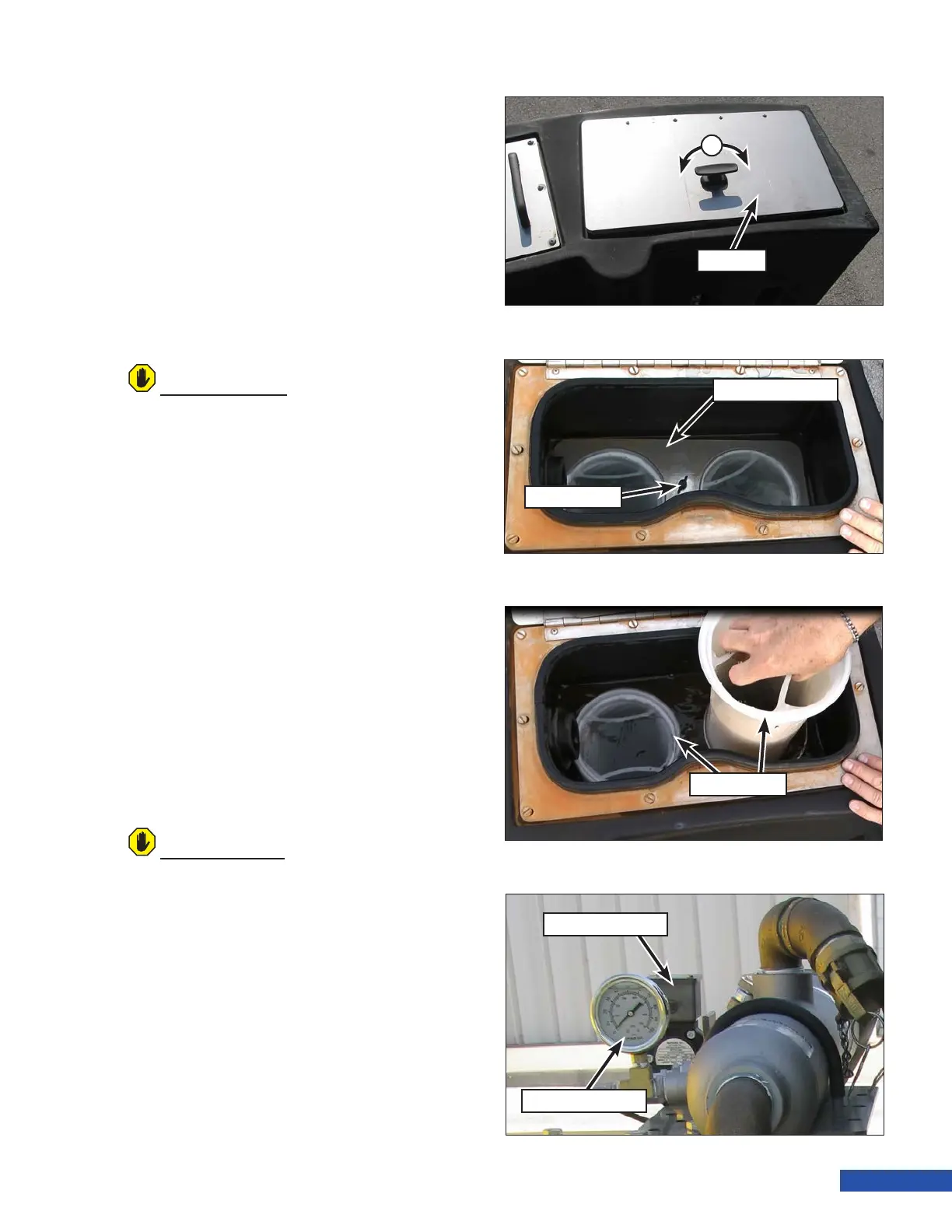

Filter Inspection

1. Rotate the handle (Figure 52, A) on the l-

ter cover (Figure 52) and swing the cover

open.

2. Unscrew the wing screw (Figure 53) that

holds the lter retainer plate in place.

3. Remove the lter retainer plate.

4. Lift the lter bags (Figure 54) from the

tank and inspect for debris. Replace as

necessary.

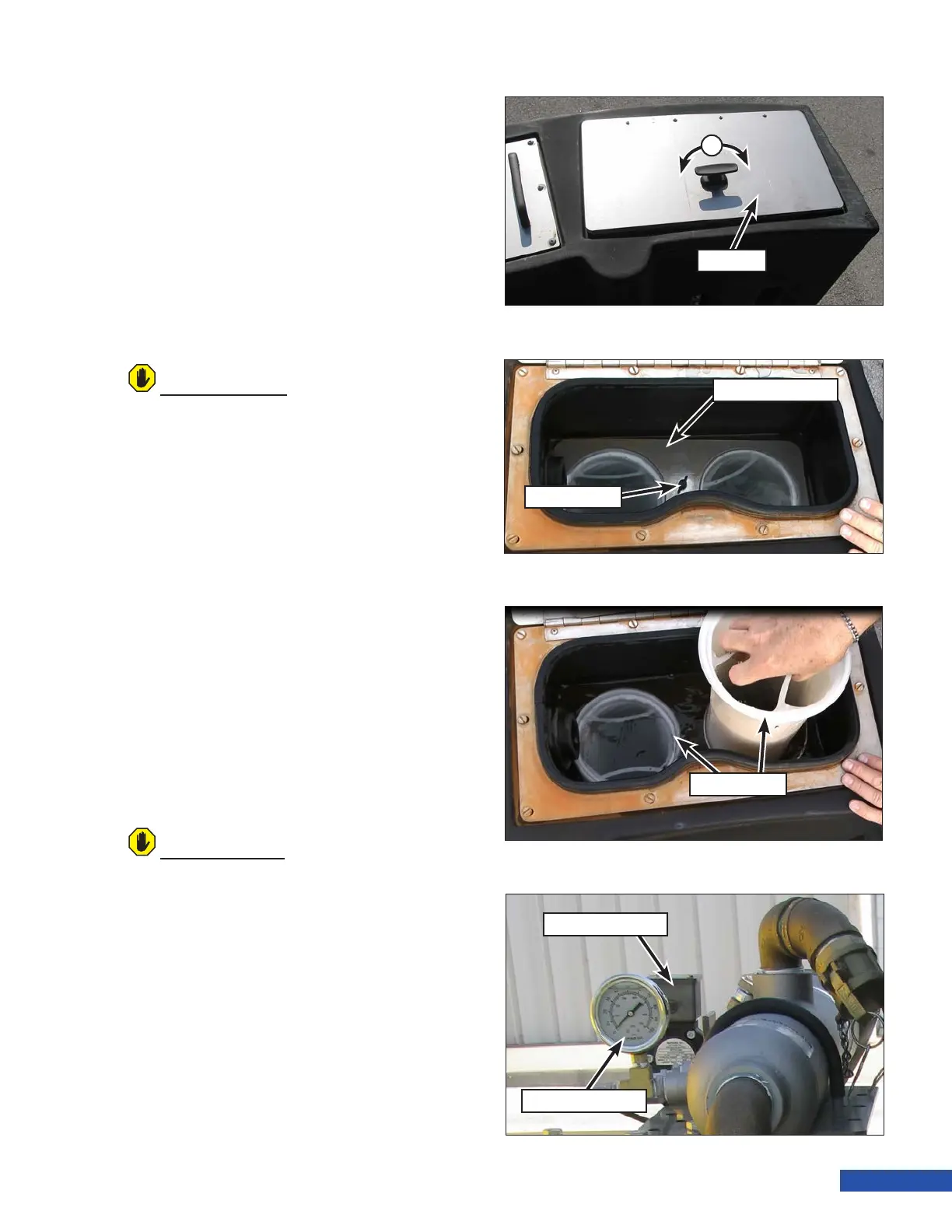

Secondary Filter (40k Operation Only)

The secondary lter, or polishing lter, is used

for 40K operation only. When operating at 40K,

monitor the lter pressure gauge (Figure 55)

for an indication of lter condition. During

normal operation, the pressure gauge should

be within the 30 to 40 psi (2 to 2.75 bar) range.

When differential pressure inside the lter

housing between the clean side and the dirty

side drops approximately 7 to 10 psi (0.48 to

0.69 bar), the pressure switch on the lter

housing will trip and the engine will shut off to

protect the unit from damage. Replace the

dirty lter cartridge if this occurs.

ATTENTION

Filter bags are not washable. Any attempt to wash

or ush a bag for reuse could damage the bag.

This may allow debris past the lter and into the

valves causing damage.

ATTENTION

Extended operation with a dirty lter will lead to

lter failure and allow debris to reach the valves

causing damage to the valves.

It is important to know the condition of your

lter cartridge. Standard units come with a

pressure gauge on the lter. In order to monitor

the condition of the lter it is important to note

the engine operating speed and housing pressure

when the lter is rst changed. Refer to “Filter

Cartridge Replacement” on page 42 for more

information.

Figure 52: Filter Cover

Cover

A

Figure 53: Retainer Plate Removal.

Retaining Plate

Wing Screw

Filter Bags

Figure 54: Filter Bag Removal.

Figure 55: Secondary Filter Assembly.

Pressure Gauge

Pressure Switch

Loading...

Loading...