80

Operation Manual

6. Measure the attened plasti-gauge using

the gauge wrapper (Figure 161).

7. If the thickness of the plasti-gauge

exceeds 0.012 in. (0.31 mm), replace the

bearings. If the bearings do not exceed

the criteria, the bearings can be reused.

Note: New part clearances are as fol-

lows:

• Series 3000: 0.001 in. (0.025 mm) - 0.005

in. (0.13 mm)

• Series 3600/4200: 0.002 in. (.05 mm) -

0.005 in. (0.13 mm)

Installation

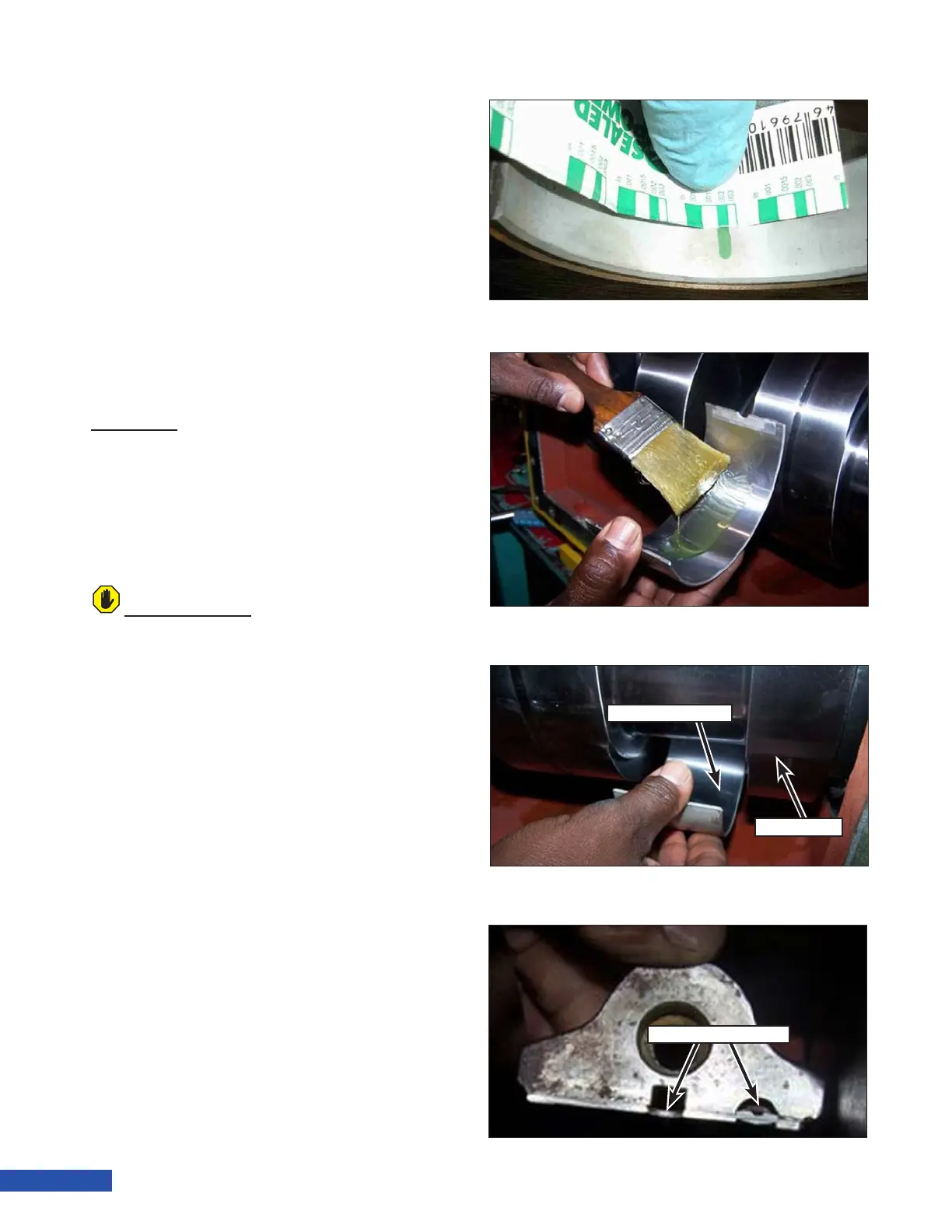

1. Apply clean new oil to the new connecting

rod journal bearing (inner diameter only)

(Figure 162).

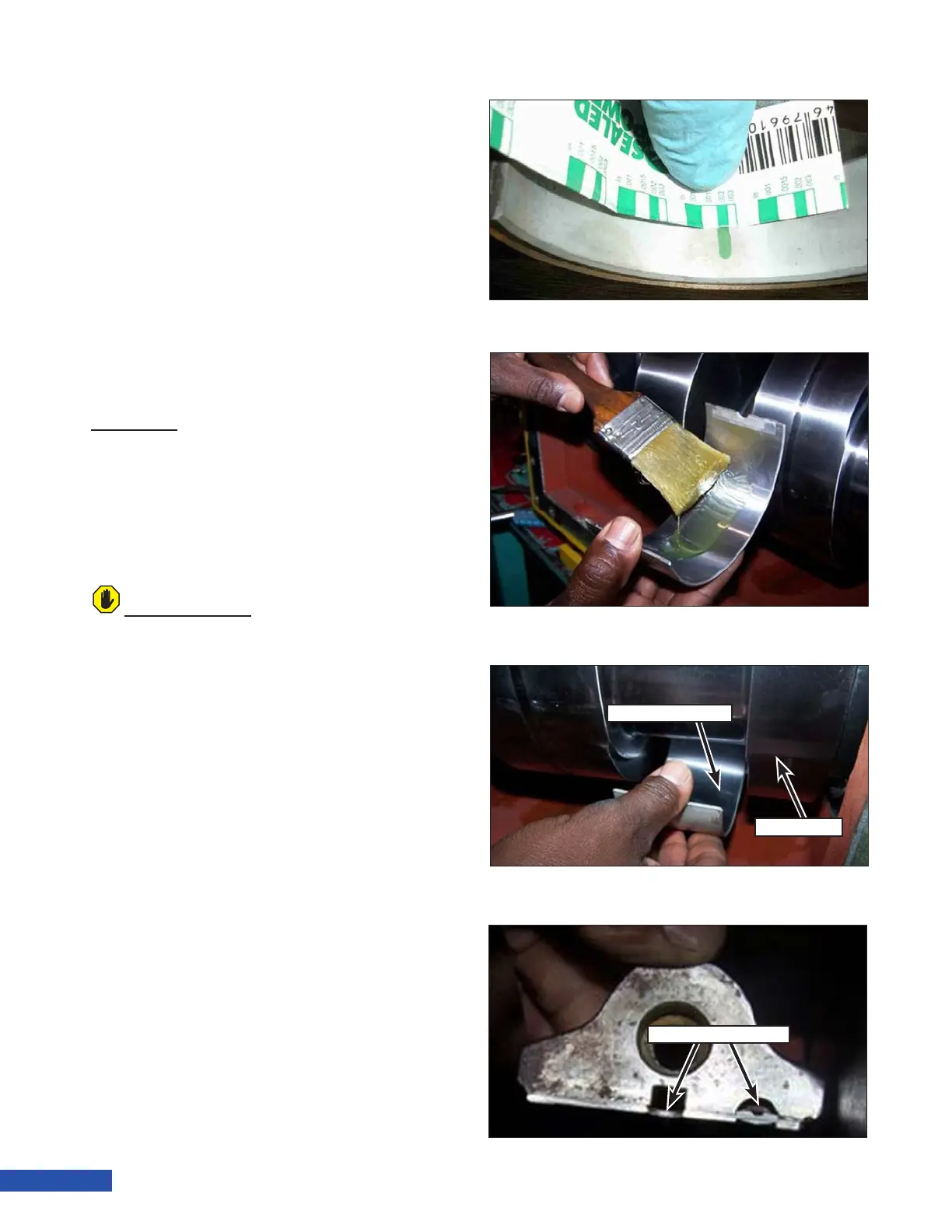

2. Slide the bearing (Figure 163) into the

connecting rod from below the crankshaft

journal.

3. Apply oil to the inner surface of the cap

end bearing.

4. Properly orient the grooves and install the

bearing in the rod cap.

5. Place the two capscrews into the rod cap.

ATTENTION

The journal bearings have tabs that match the

inner diameter of the connecting rods. Ensure the

bearings are properly oriented in the tabs when

installing (Figure 164).

Figure 161: Plasti-Gauge Measurement.

Figure 162: Lubricating the Bearing.

Figure 163: Rod Bearing installation.

Journal Bearing

Crankshaft

Figure 164: Bearing Grooves.

Bearing Grooves

Loading...

Loading...