87

X-Series Waterblast Unit

10. Remove the side plate and shims while

supporting the crankshaft. Keep the shims

together.

11. Using a wood block and a hammer, hit

either end of the crankshaft to unseat it

from its bearing bores.

12. Install two threaded rods (1 in.-8NC x 8 in.)

into the ends of the crankshaft to aid in

removal.

13. Using two people, lift the crankshaft from

the power frame. The weight of the crank-

shaft is approximately:

• 3000 Series: 125 lb. (57 kg)

• 3600/4200 Series: 325 lb. (147 kg)

14. Remove the bearings from the crankshaft.

Contact Jetstream for assistance with this

task.

Installation

1. Heat the crankshaft bearings in a 250°F

(121°C) oven for 20 minutes. Check the

bearing color as they are heated. If the

bearings turn blue or black they are over-

heated.

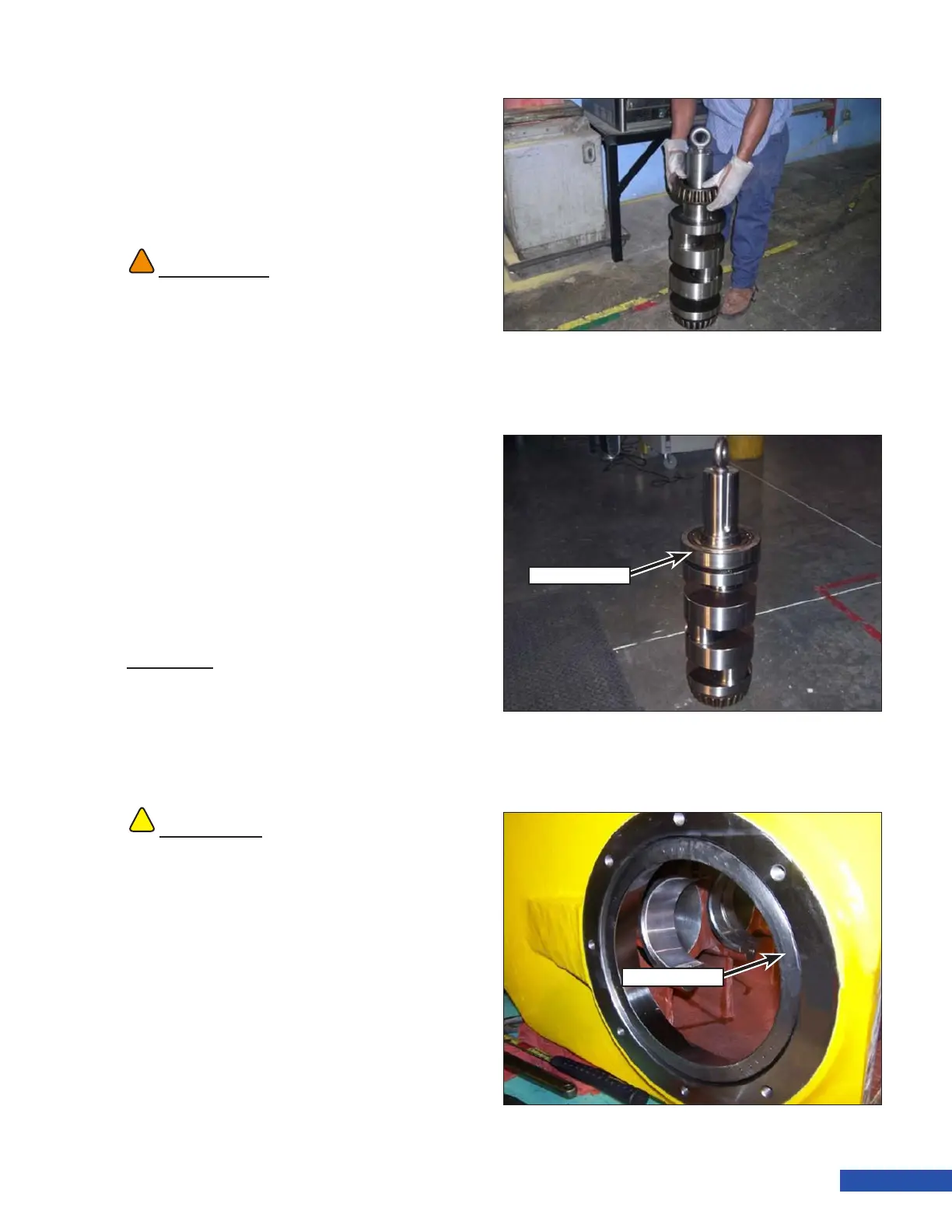

2. When ready, slide the bearings onto each

end of the crankshaft until they are fully

seated (Figure 181).

3. Verify that the bearing turns on the shaft.

4. Allow the crankshaft assembly to cool.

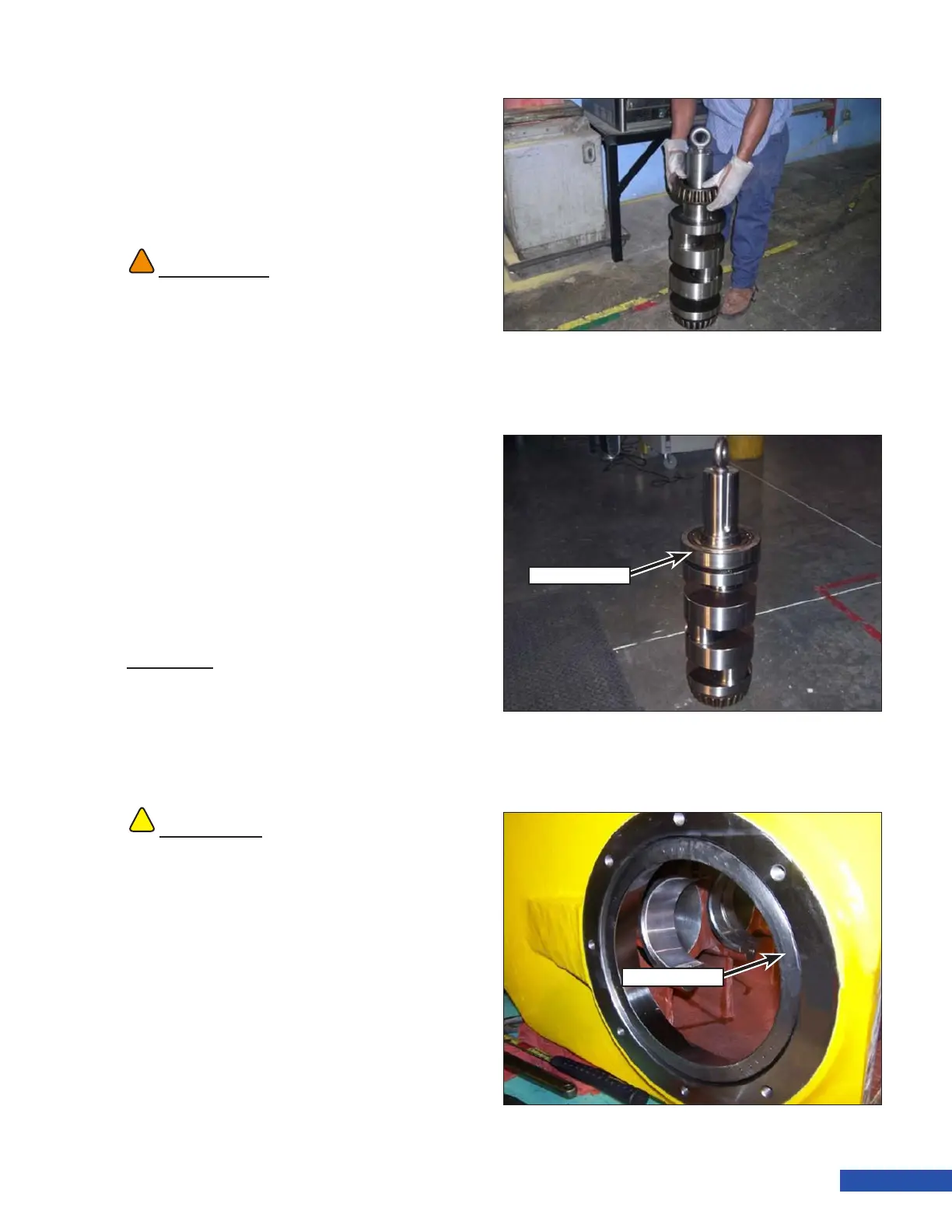

5. Install the outer bearing race (Figure 182)

onto the inboard bearing.

6. Install the outer bearing race (Figure 183)

into the power frame using a rubber mal-

let. Install the race so it is ush with the

face of the case.

WARNING

!!

Use caution when unseating the crankshaft. The

crankshaft will fall approximately 1 in. (25 mm)

as it slides out of the tapered race and can cause

bodily harm.

!!

CAUTION

Temperatures in excess of 250°F (121°C) will

damage the bearing. If the bearings have been

heated over the limit, discard the bearings.

Figure 181: Bearing Installation.

Figure 182: Outer Race Installation.

Outer Race

Figure 183: Bearing Race Installation.

Bearing Race

Loading...

Loading...