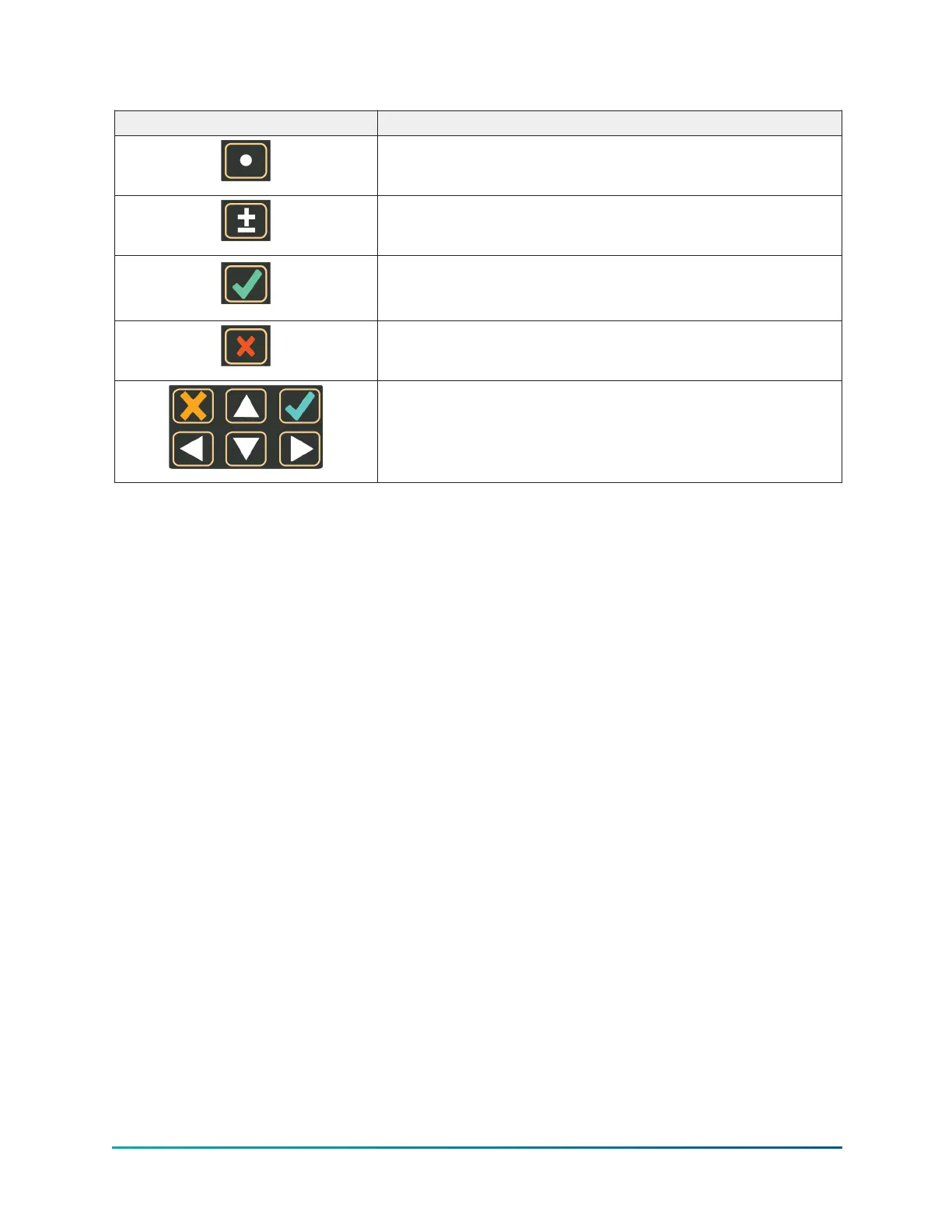

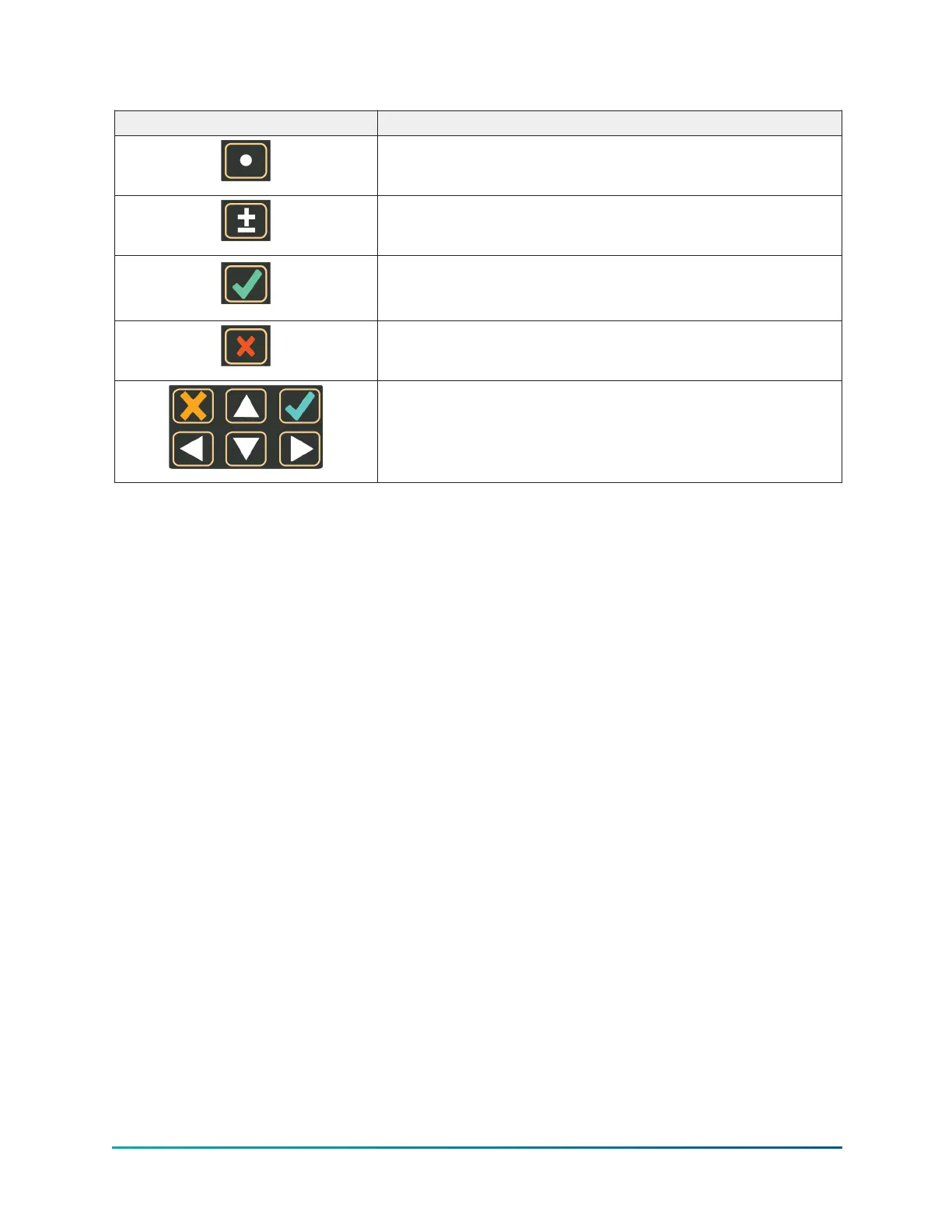

Table 2: OptiView control center buttons

Button Description

The Decimal button provides accurate entry of setpoint

values.

A ± button has also been provided to allow entry of negative

values and AM/PM selection during time entry.

In order to accept changes made to the chiller setpoints, the

Check button is provided as a universal ‘Enter’ key or ‘Accept’’

symbol.

In order to reject entry of a setpoint or dismiss an entry form,

the ‘X’ button is provided as a universal ‘Cancel’ symbol.

Cursor Arrow buttons are provided to allow movement

on screens which contain a large amount of entry data. In

addition, these buttons can be used to scroll through history

and event logs.

The graphic display also allows numerical information to be represented in both English

(temperatures in °F and pressures in psig) and Metric (temperatures in °C and pressures in kPa)

mode. It also has the ability to display many languages.

The control center continually monitors the system operation and records the cause of any

shutdowns (Safety, Cycling, or Normal). This information is recorded in memory and is preserved

even through a power failure condition. The user may recall it for viewing at any time. During

operation, the user is continually advised of the operating conditions by various status and warning

messages. In addition, it may be configured to notify the user of certain conditions via alarms. A

complete listing of shutdown, status, and warning messages is attached in Display messages.

The control center includes capabilities for remote control and communications. Common

networking protocol through the Building Automation System (BAS) allows increased remote

control of the chiller, as well as 24-hour performance monitoring via a remote site. An optional

circuit board called the SC-EQUIP provides Johnson Controls and YORK mechanical equipment such

as the YMC

2

chiller with building automation system (BAS) networking connectivity.

The chiller also maintains the standard digital remote capabilities as well. Both of these remote

control capabilities allow for the following standard Energy Management System (EMS) interfaces.

The actual connection details are in the Field Connections section of the Wiring Diagram (Form

160.84-PW1 and PW3):

• Remote Start

• Remote Stop

• Remote Leaving Chilled Liquid Temperature Setpoint adjustment: BAS coms, Analog signal,

(0-10 VDC, 2-10 VDC, 0-20 mA or 4-20 mA) or pulse width modulation (PWM)

• Remote Current Limit Setpoint adjustment: BAS coms, Analog signal, (0-10 VDC, 2-10 VDC, 0-2

0mA or 4-2 0mA) or pulse width modulation

• Remote “Ready to Start” Contacts

• Safety Shutdown Contacts

• Cycling Shutdown Contacts

YMC

2

Mod B with OptiView

™

Control Center

14

Loading...

Loading...