Chilled liquid control settings

Temperature control setpoint

The temperature to which the chiller will control the chilled fluid leaving the evaporator must be set

by the Operator. The way it is selected depends whether the Operator wants this value set locally or

modulated by a remote input.

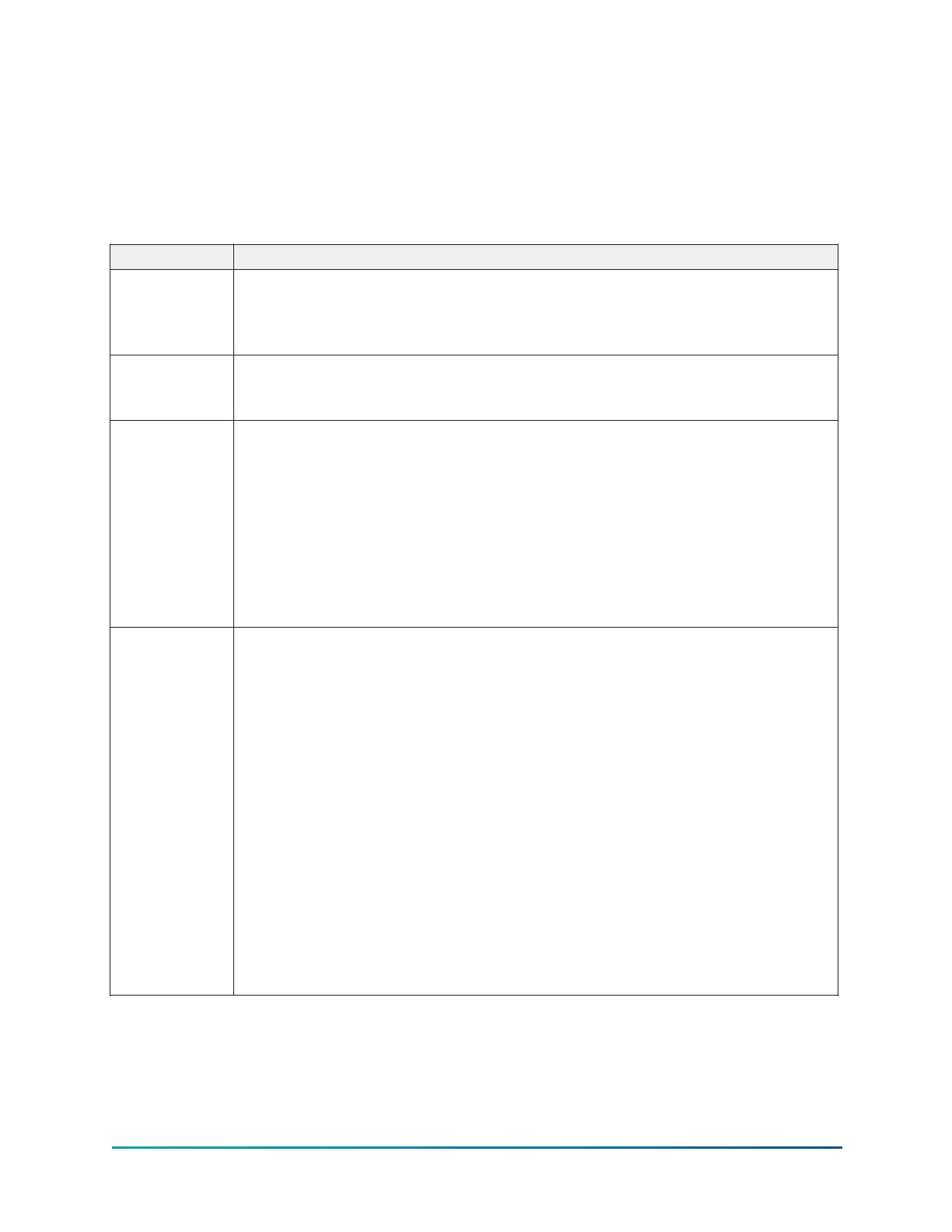

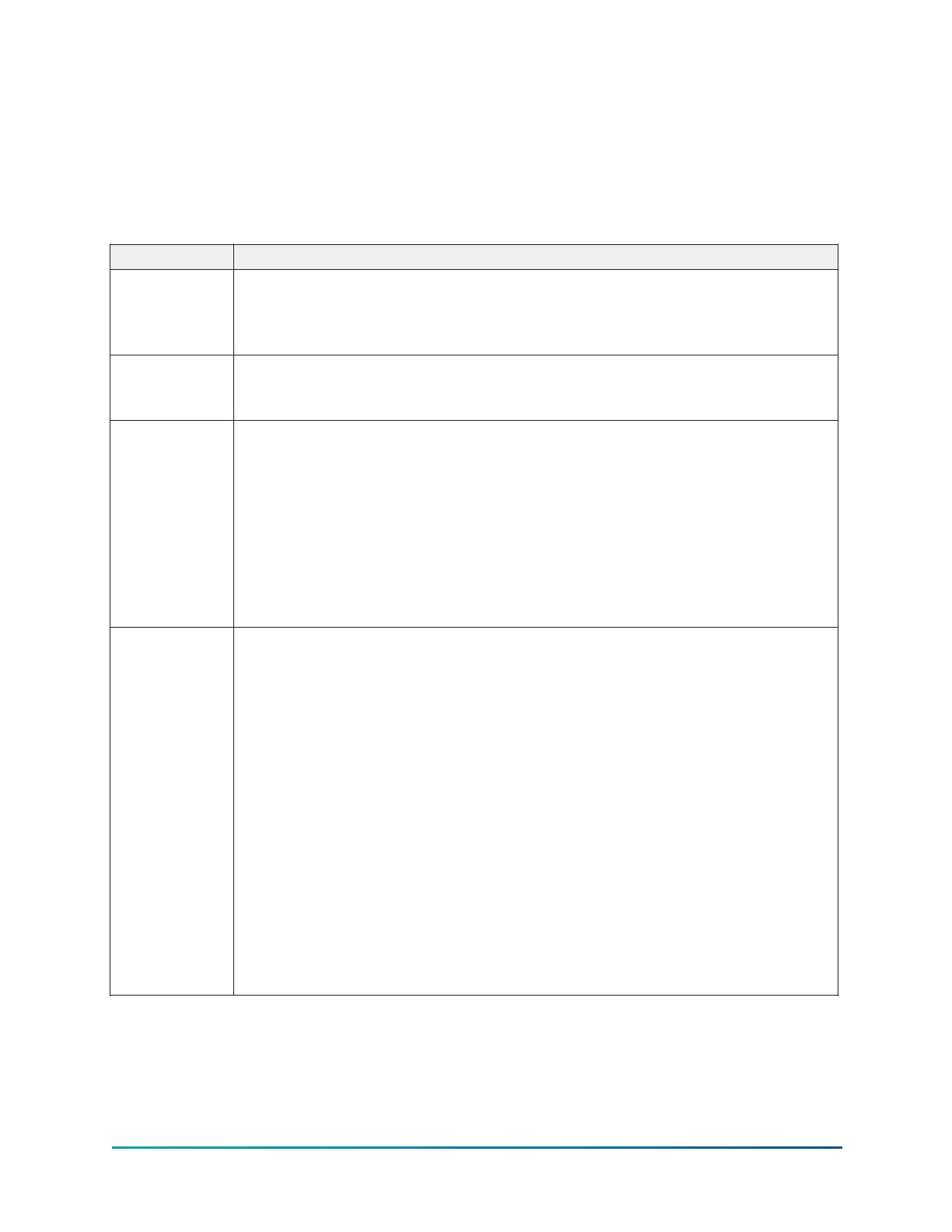

Table 4: Temperature setpoint

Control source Leaving chilled liquid temperature setpoint

Local

Local Leaving Chilled Liquid Temperature Setpoint, entered from the panel. It

is programmable over the range of 38.0°F to 70.0°F (water) or 10.0°F to 70.0°F

(brine). If Smart Freeze (see previous) is enabled, the range is 36.0°F to 70.0°F

(water). The default is 45 °F.

ISN (BAS)

Remote Leaving Chilled Liquid Temperature Setpoint value sent over

communications. The setpoint entered from the panel is ignored. If nothing is

written to the address, the default is 45 °F.

Analog Remote

Local Leaving Chilled Liquid Temperature Setpoint, entered from the panel plus

the temperature offset defined by the remote analog input signal. A remote

device can provide an analog signal (0 mA to 20 mA, 4 mA to 20 mA, 0 VDC to 10

VDC or 2 VDC to 10VDC) that creates the temperature offset in Analog Remote

mode. The span of the offset may be defined as 10ºF, 20ºF, 30ºF, or 40ºF using

the Local Leaving Chilled Liquid Temperature Range setting from the panel. For

example, if this Range Setpoint is programmed for 10°F and the Local Leaving

Chilled Liquid Temperature Setpoint is 45°F, then the remote device can set the

Leaving Chilled Liquid Temperature setpoint over the range 45.0ºF to 55.0°F as its

voltage or current changes from minimum to maximum.

Digital Remote

Local Leaving Chilled Liquid Temperature Setpoint, entered from the panel plus

the temperature offset defined by the remote pulse width signal. A remote device

can provide a Pulse Width Modulation (PWM) signal in Digital Remote mode that

creates the temperature offset in Digital Remote mode. The span of the offset

may be defined as 10ºF, 20ºF, 30ºF, or 40ºF using the Local Leaving Chilled Liquid

Temperature Range setting from the panel. For example, if this Range Setpoint is

programmed for 10°F and the Local Leaving Chilled Liquid Temperature Setpoint

is 45°F, then the remote device can set the Leaving Chilled Liquid Temperature

setpoint over the range 45.0ºF to 55.0°F as its pulse duration changes from

minimum to maximum. The PWM input is in the form of a 1 to 11 second relay

contact closure that applies 115 VAC to the I/O Board TB4- 19 for 1 to 11 seconds.

A contact closure time (pulse width) of 1 second produces a 0°F offset. An 11

second closure produces the maximum offset. The relay contacts should close

for 1 to 11 seconds at least once every 30 minutes to maintain the setpoint to the

desired value. If a 1 to 11 second closure is not received within 30 minutes of the

last closure, the offset is defaulted to zero. A closure is only accepted at rates not

to exceed once every 70 seconds. Offset (°F) = (pulse width in seconds – 1)( Local

Leaving Chilled Liquid Temperature Range) divided by 10.

Regardless of which method is used to select the desired Leaving Chilled Liquid Temperature

(LCHLT), the chiller controls to its own Active LCHLT Setpoint. The Active Setpoint is a target to the

programmed setpoint. When the chiller is not running, the Active Setpoint is set to Entering Chilled

Liquid Temperature minus a programmable offset (default 5°F), but not adjusted to less than the

programmed LCHLT setpoint. When the compressor motor starts, the Active LCHLT Setpoint is

21

YMC

2

Mod B with OptiView

™

Control Center

Loading...

Loading...