The Start/Stop control depends whether the chiller Control Source is set to Local or one of the

Remote types from the chiller Setup - Operations screen. Start is operated:

• only the keypad when the chiller is set to local mode,

• remotely through digital inputs in digital or analog remote mode but local keypad start must

be pressed initially to enable the run permissive, or

• by the SC-EQUIP in BAS (ISN) remote mode but local keypad start must be pressed initially to

enable the run permissive.

To start the chiller press the START key on the Home Screen on the display panel. In LOCAL

control source, the chiller then starts. In remote ISN, ANALOG, DIGITAL, or MODEM a remote start

command must also be provided to the correct input connection.

When the control is changed to local mode from any other source, it will remain in RUN if already

running or remain in STOP if already stopped. A hardware Safety Stop button is also located on the

side of the panel.

The chiller will start if the following conditions are met:

• Leaving Chilled Liquid Temperature is above the setpoint

• Chilled liquid flow is established

• Condenser liquid flow is established

• No uncleared faults or start inhibits exist

Chiller operation

Upon start request, the following occur in sequence:

1. Chiller's system pump run contacts close

2. VSD pre-charges (~12 seconds)

3. VSD pre-regulates (~3 seconds)

4. Motor runs

The chiller will vary capacity to maintain the leaving chilled liquid temperature setpoint by a specific

sequencing of optional hot gas bypass, variable geometry diffuser, and compressor speed.

Throughout capacity control, the compressor speed is maintained above the minimum required

for the prevailing head condition, to avoid surge. Otherwise, the device maintaining capacity is

controlled by a proportional-integral-derivative control based on leaving chiller liquid temperature.

Pressure and motor current overrides also apply as necessary to maintain operating limits.

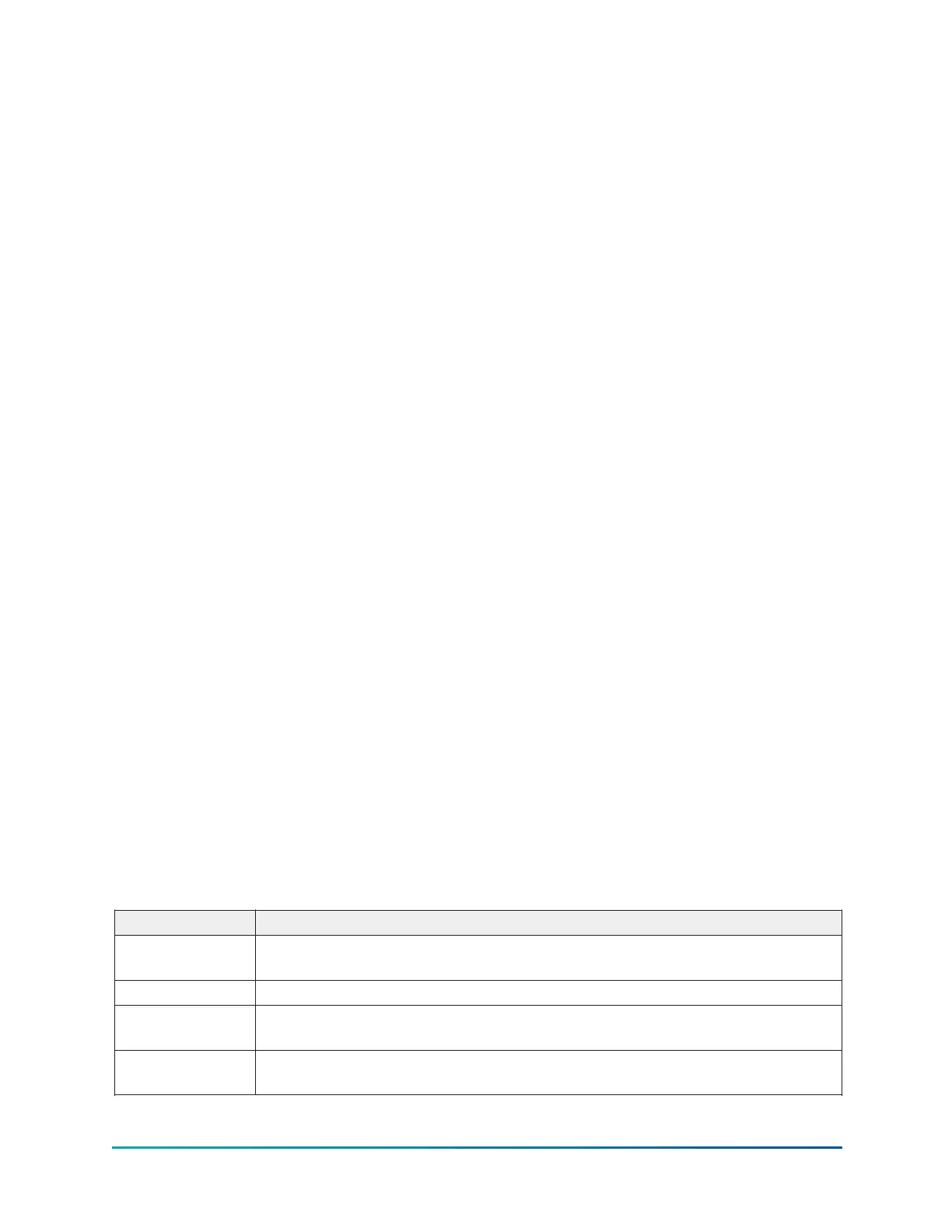

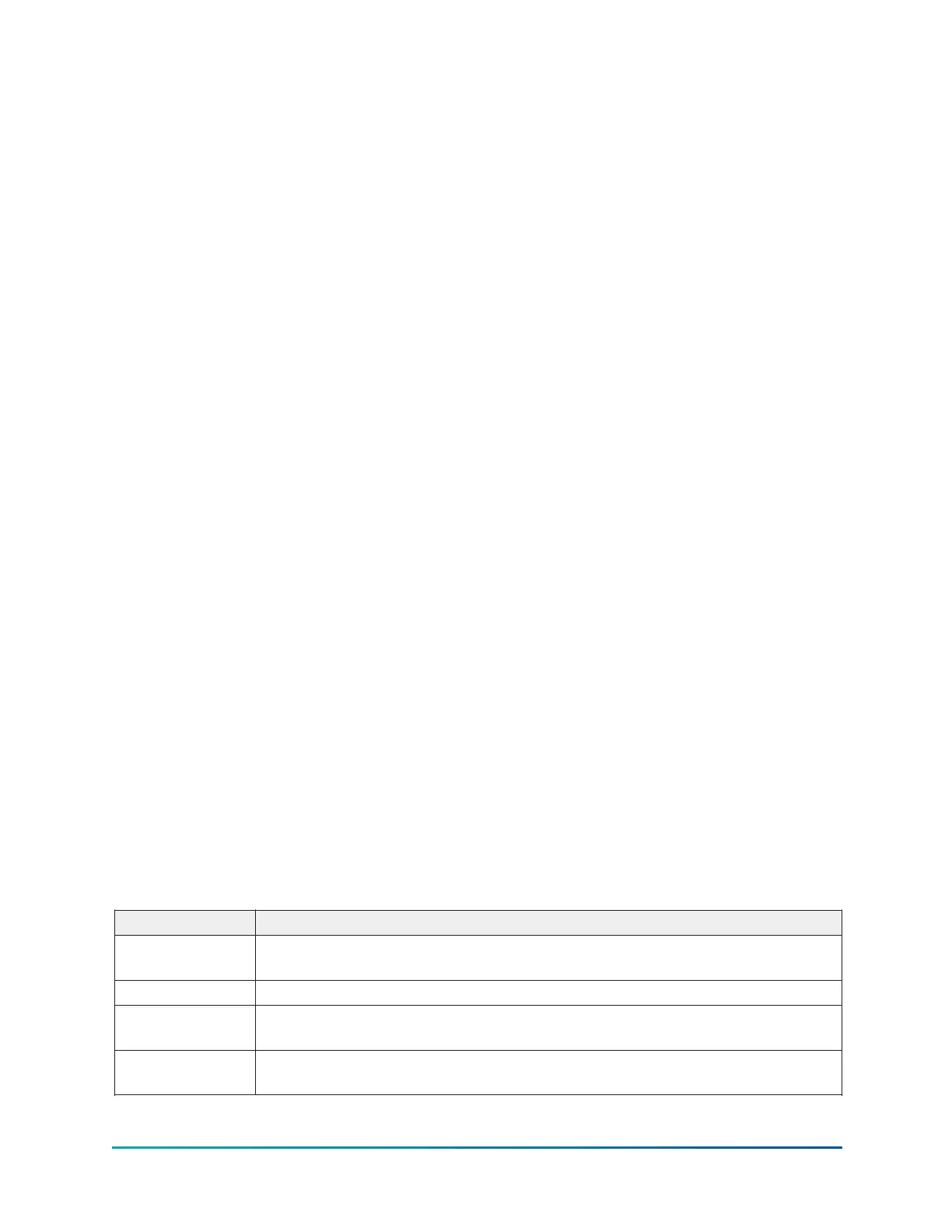

The Input Current limit threshold value is determined from several settings, depending on the

chiller control source selected according to the Table 3.

Table 3: Input current limit threshold

Control source Active input current limit threshold

Local

Lowest of: Local Input Current Limit Setpoint (% Input Job FLA) Pulldown Input

Current Limit (when active)

ISN Remote Input Current Limit Setpoint (comms)

Analog Remote

Lowest of: Local Input Current Limit Setpoint (% Input Job FLA) Analog Remote

Input Current Limit Setpoint Pulldown Input Current Limit (when active)

Digital Remote

Lowest of: Local Input Current Limit Setpoint (% Input Job FLA) Digital Remote

Input Current Limit Setpoint Pulldown Input Current Limit (when active)

YMC

2

Mod B with OptiView

™

Control Center

20

Loading...

Loading...