MODEL

(Btu/h)

Static Pressure

(Pa/in.wg)

0~100/0~0.4

18K

0~160/0~0.64

24K

0~160/0~0.64

30K~36K

0~160/0~0.64

42K~60K

0~50/0~0.2

9K

0~50/0~0.2

12K

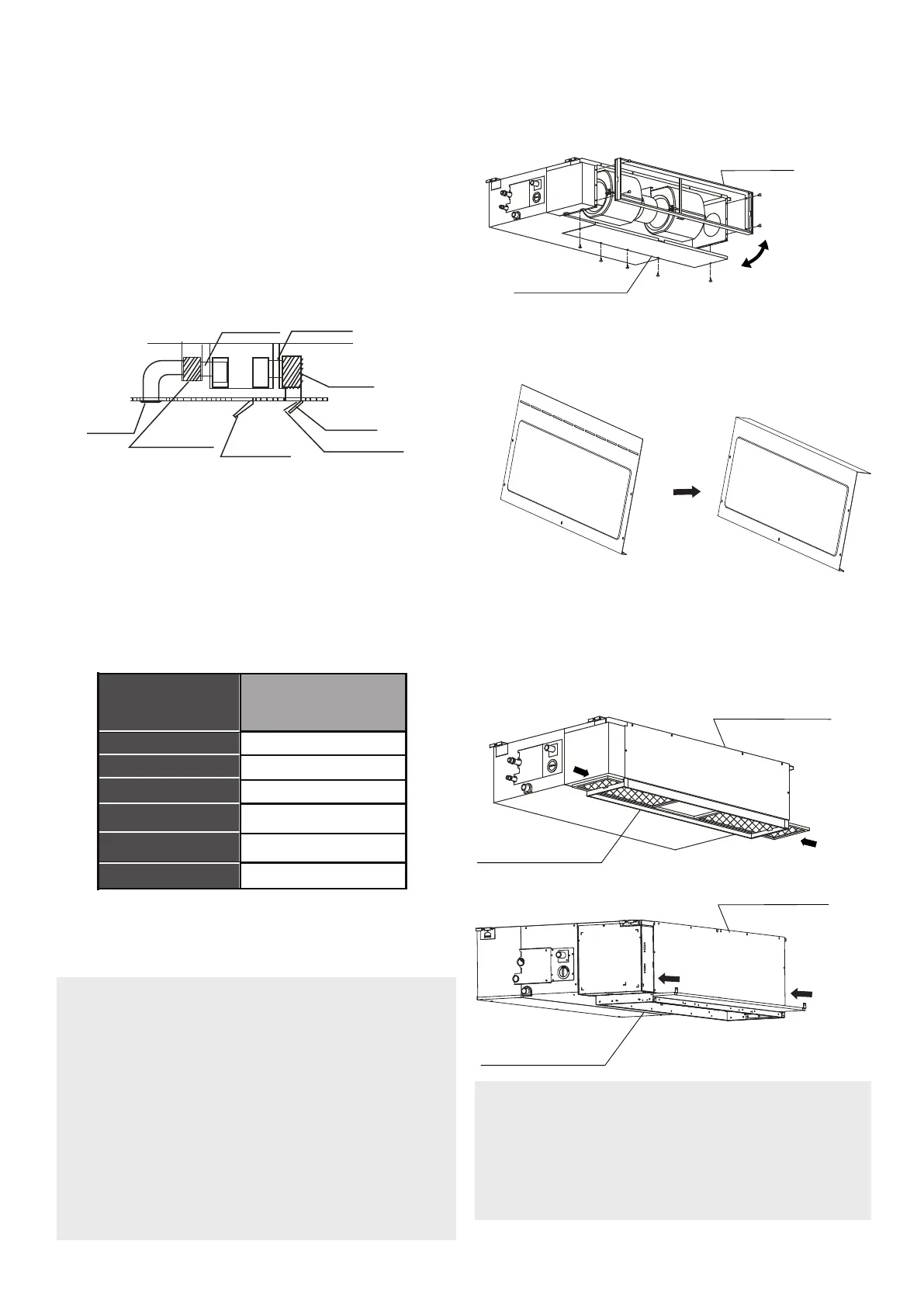

Step 3: Duct and accessories installation

NOTE:

Do not place the connecting duct

weight on the indoor unit. When

connecting the duct, use a non-

flammable canvas tie-in to prevent

vibrating.

Insulation foam must be wrapped

outside the duct to avoid conden-

sation. An internal duct underlayer

can be added to reduce noise, if

the end-user requires.

NOTE:

The min. length of the duct should be

more than 1m, and fix on the air inlet by

screws (applicable to the unit that the

air inlet filter is not fasten by screws).

5. Refer to the following static pressure

guidelines when installing the indoor

unit.

Change the fan motor static pressure

according to external duct static

pressure.

1. Install the filter (optional) according to

the size of the air inlet.

2. Install the canvas tie-in between the

body and duct.

3. The air inlet and air outlet duct should

be far enough apart enough to avoid

air passage short-circuit.

4. Connect the duct according to the

following diagram:

Canvas tie-in Canvas tie-in

Air outlet

Isolation booth

Isolation booth

Checking orifice

Air inlet

Air dust filter

Step 4: Adjust the air inlet direction

(From rear side to under-side)

1. Take off the ventilation panel and flange.

Air return flange

Ventilation panel

2. Change the mounting positions of the

ventilation panel and air return flange.

3. When installing the filter mesh, fit it

into the flange as illustrated in the follo-

wing figure.

NOTE: All the figures in this manual

are for demonstration purposes

only. The air conditioner you have

purchased may be slightly different

in design, though similar in shape.

Ventilation panel

Air return flange

Ventilation panel

Air return flange

Or

Bend the rear ventilation panel 90 degrees

along the dotted line into a descending

ventil

ation panel. (some models)

Loading...

Loading...