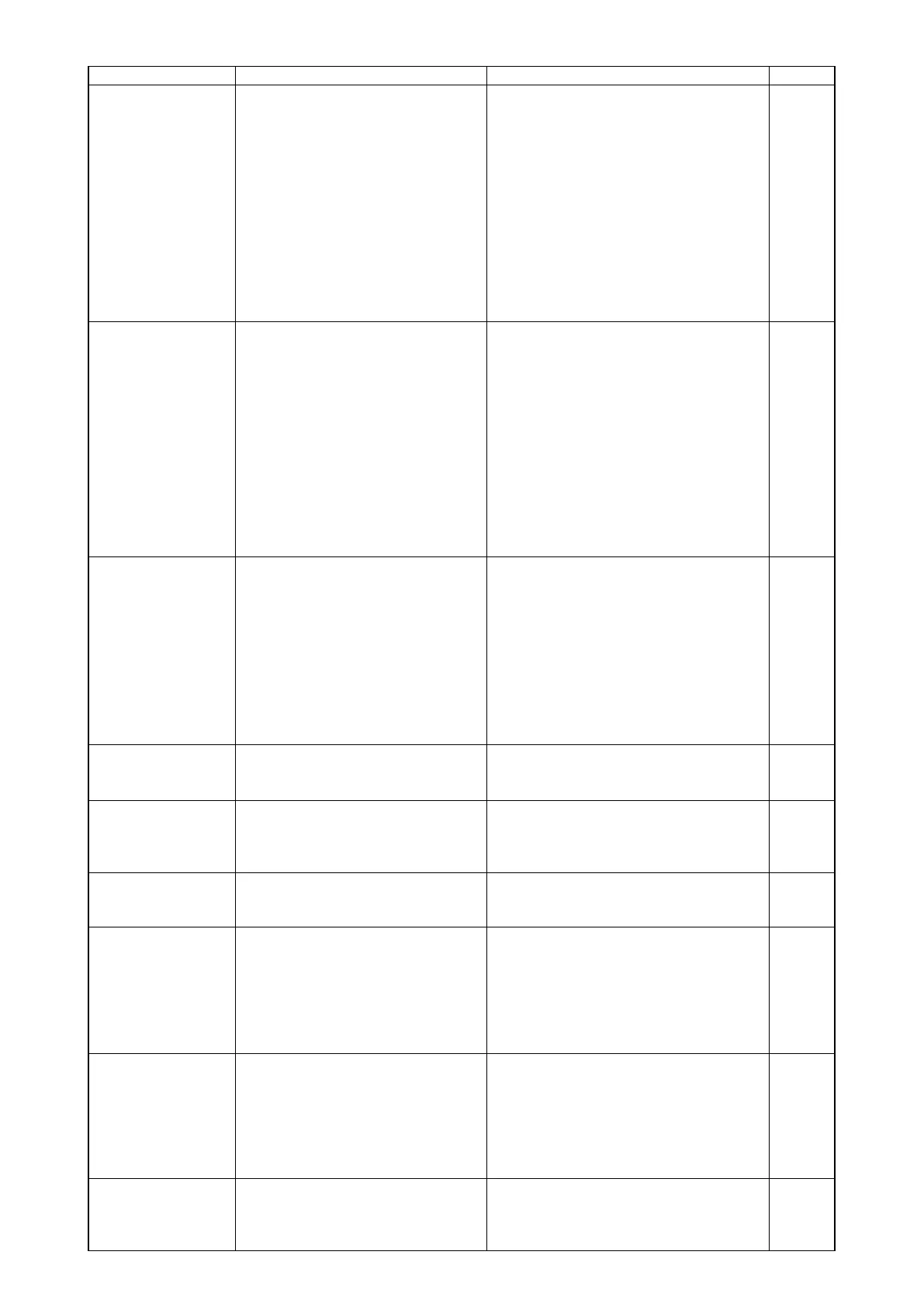

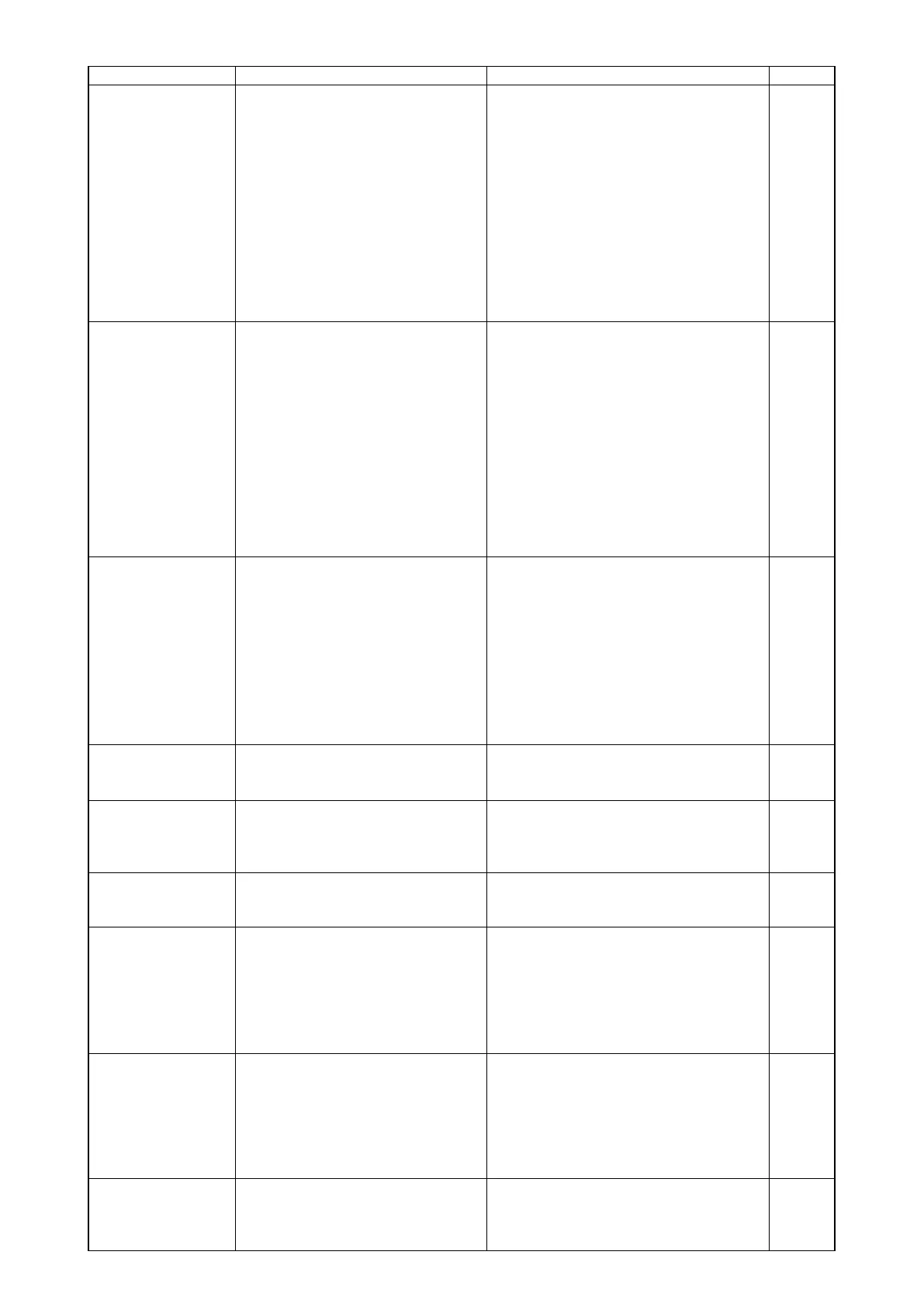

– 128 –

Trouble Cause Corrective measures Page

5. Stitch skipping

often occurs.

1

The motions of the needle

and shuttle are not properly

synchronized.

™

Correct the positions of the needle and

shuttle.

115

2

The clearance between the

needle and shuttle is too large.

™

Correct the positions of the needle and

shuttle.

115

3

The needle is bent.

™

Replace the bent needle. 18

4

The driver excessively bends the

needle.

5

Length of needle thread

remaining after thread trimming

is too long. (In the case of stitch

skipping within the 2nd to 10th

stitch from the beginning of

sewing)

™

Correctly position the driver.

™

Reduce the thread take-up spring

pressure or increase the thread

tension applied by the thread tension

controller No. 1.

115

21, 22

6. The needle

thread comes

out on the wrong

side of the

material.

1

The needle thread tension is not

high enough.

™

Increase the needle thread tension. 21

2

The tension release mechanism

fails to work properly.

™

Check whether or not the tension disc

No. 2 is released during bar-tracking.

3

The needle thread after thread

trimming is too long.

™

Increase the tension of the thread

tension controller No. 1.

™

Correct the position of the moving knife.

21

4

Number of stitches is too few.

™

Turn OFF the thread clamp.

5

When sewing length is short (End

of needle thread protrudes on the

wrong side of sewing product.)

™

Turn OFF the thread clamp.

6

Number of stitches is too few.

™

Use the lower plate, the hole of which

is larger than the presser.

7. Thread end of

the 1st stitch

comes out on

the right side of

the material.

1

Stitch skipping at the 1st stitch

™

Adjust the hook timing faster by a 1/2

stitch.

2

Needle used and thread used

are thick in terms of the inner

diameter of the intermediate

presser.

™

Increase the inner diameter of

intermediate presser.

3

Intermediate presser is not

properly positioned in terms of

the needle.

™

Adjust the eccentricity between

intermediate presser and needle so

that needle enters in the center of

intermediate presser.

8. Threads break

at time of thread

trimming.

1

The moving knife has been

improperly position.

™

Correct the position of the moving

knife.

118

9. The thread

clamp is

entangled with

needle thread.

1

The needle thread at the sewing

start is too long.

™

Tighten thread tension controller No. 1

and make the length of needle thread

40 to 50 mm.

25

10. Uneven length

of the needle

thread

1

The tension of thread take-up

spring is too low.

™

Increase the tension of the thread

take-up spring.

22

11. The length of

needle thread

does not

become short.

1

The tension of thread tension

controller No. 1 is too low.

™

Increase the tension of thread tension

controller No. 1.

21

2

The tension of thread take-up

spring is too high.

™

Decrease the tension of thread take-

up spring.

22

3

The tension of thread take-up

spring is too low and motion is

unstable.

™

Increase the tension of thread take-

up spring and lengthen the stroke as

well.

12. The knotting

section of

bobbin thread

at 2nd stitch at

the sewing start

appears on the

right side.

1

Idling of bobbin is large.

™

A just the position of the moving knife. 118

2

The bobbin thread tension is too

low.

™

Increase the bobbin thread tension. 21

3

The needle thread tension at 1st

stitch is too high.

™

Decrease the needle thread tension at

1st stitch.

™

Turn OFF the thread clamp.

13. Wiper fails to

work. (Return is

defective.)

1

Needle entry of the last needle

is the same as that of the sewing

start, and the resistance of

thread and cloth is large.

™

Shift the needle entry point of the last

needle.

Loading...

Loading...