SECTION 7

HIGH PRESSURE WATER

Jan 2001

Page 7-15

05114624

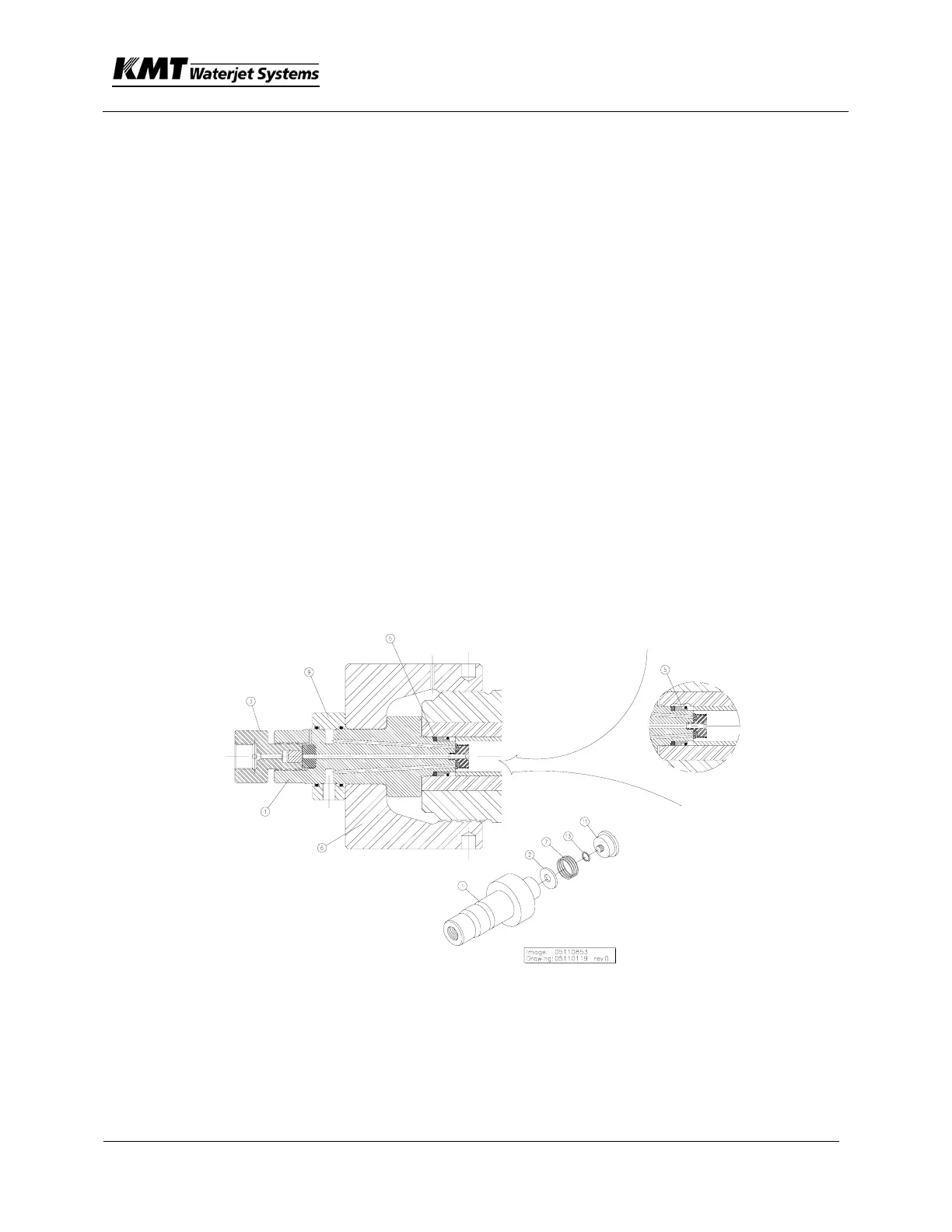

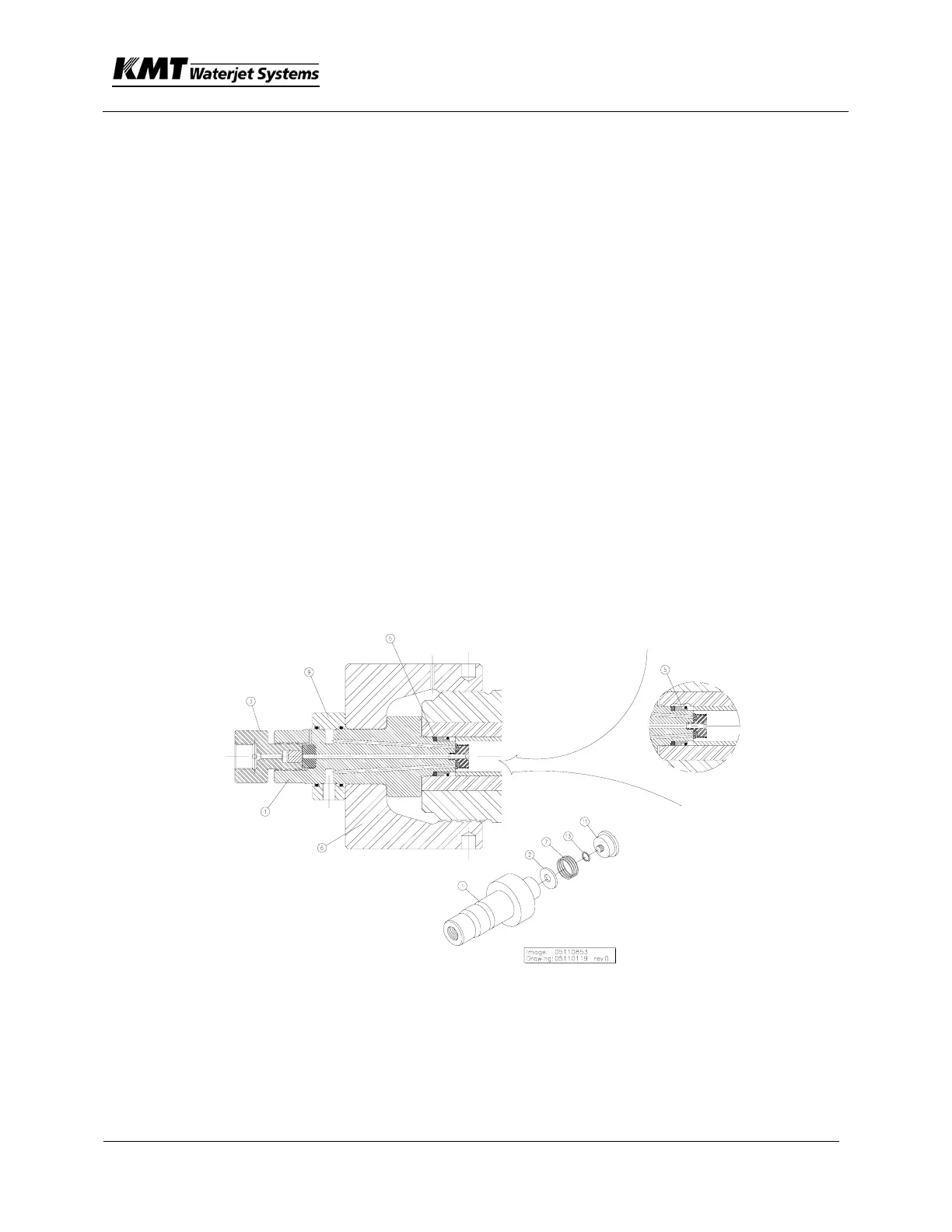

7.3.2 Inlet Check Valve

1. Use a ½” flat bladed screwdriver to unscrew the poppet retainer from the

sealing head. The inlet check valve is disassembled.

2. Inspect and refinish the sealing head face seal surface per instructions in

Section 7.3.3.

3. Inspect both surfaces of the flat washer shaped poppet. If one surface is

marred, and the opposite surface is not, the poppet may be reversed with

the best surface facing the sealing head. If both sides are worn, replace

poppet.

4. Insure the poppet retainer threads, and the mating threads in the port

sealing head are clean and dry. Install small O-ring over threads.

5. Assemble the inlet poppet, spring, and retainer to the sealing head using a

½” flat blade screwdriver.

6. Inspect the assembled unit to insure the following:

• The poppet moves freely.

• The spring is fully guided on the poppet retainer.

• The spring end is 90° from the retainer’s screwdriver slot.

• The poppet retainer is shouldered against the sealing head.

• O-ring is sandwiched between poppet and body.

Item Description

(1) Sealing Head (2) Poppet (3) Gland Nut

(5) Head Seal (6) Head Nut (7) Suction Spring

(9) Collar (11) Retainer (13) O-Ring

Loading...

Loading...