392616/B

41

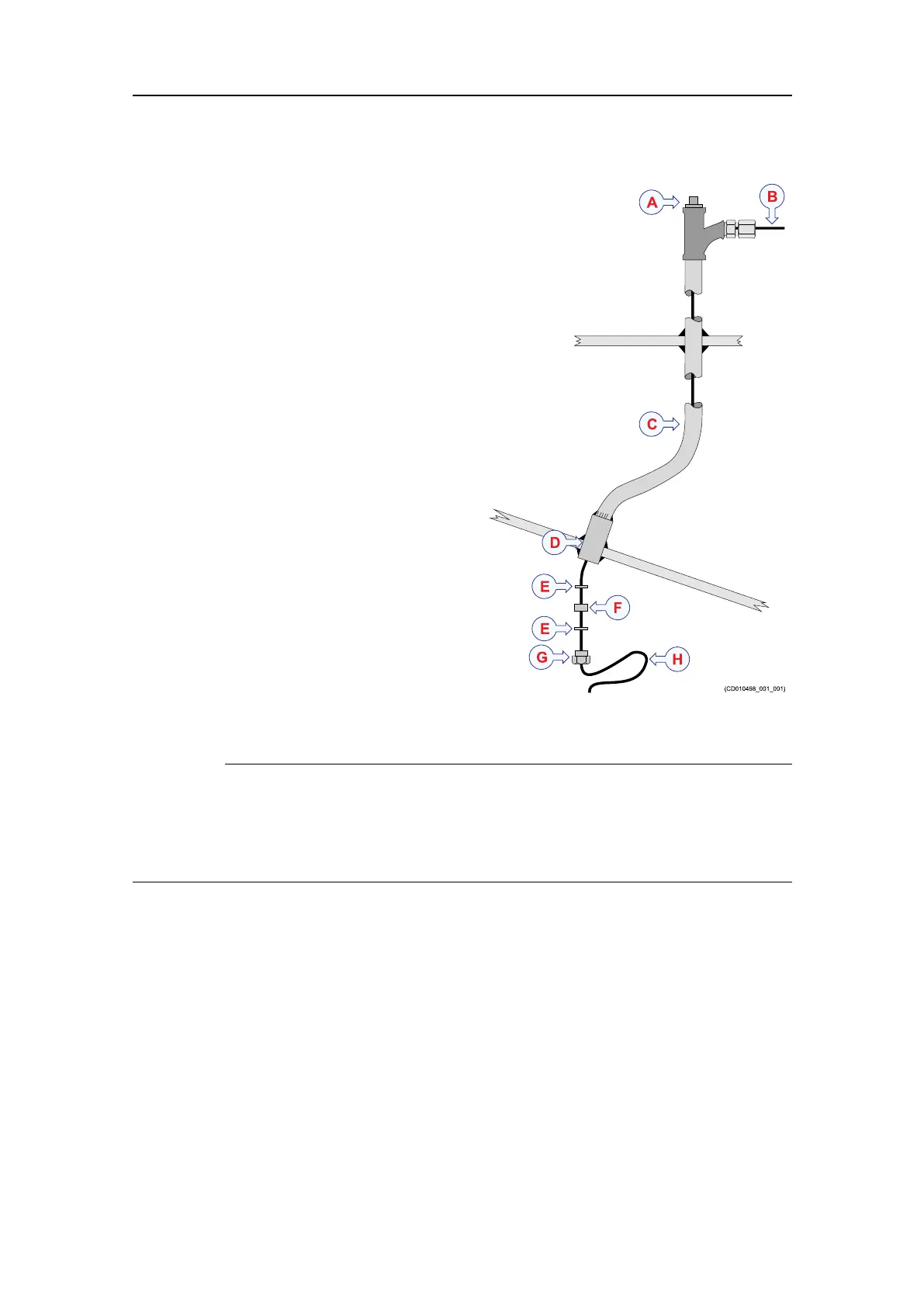

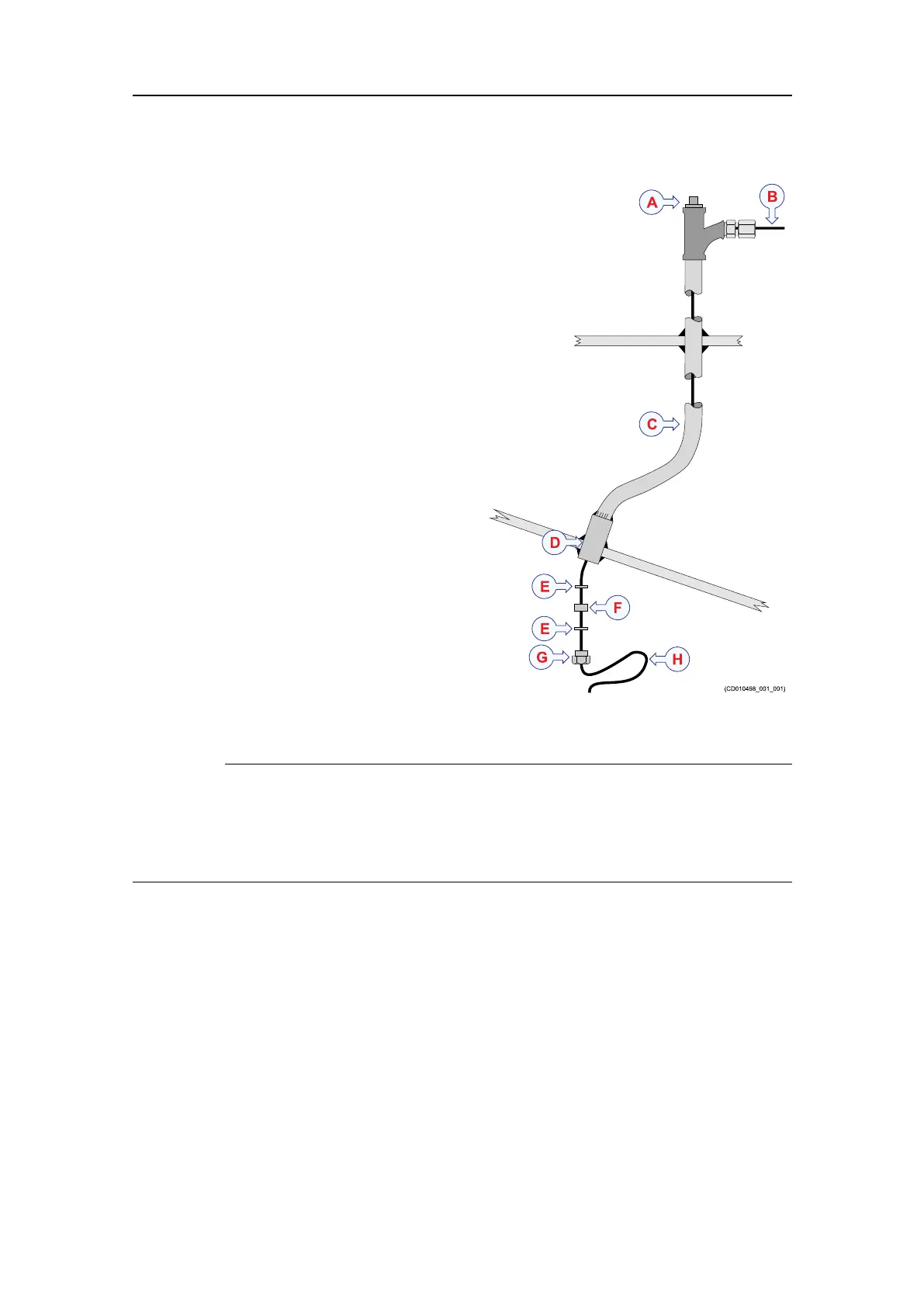

AServiceaccess(optional)

BTotransceiver

CSteelconduit

DBushing,penetratesthehullplating

EWasher

FRubbergasket

GPackingnut

HCableserviceloopoverthetransducer

Context

Theinstallationshipyardmustprovideall

necessarydesignandinstallationdrawings,

aswellastherelevantworkstandards

andmountingprocedures.Ifrequired,all

documentsprovidedbytheshipyardforthe

physicalinstallationoftheEA440mustbe

approvedbythevessel’snationalregistry

andcorrespondingmaritimeauthority

and/orclassicationsociety.Suchapproval

mustbeobtainedbeforetheinstallation

canbegin.Theshipownerandshipyard

doingtheinstallationareresponsiblefor

obtainingandpayingforsuchapproval.

Important

Finalizethesteelconduitinstallationbeforeyoupullthetransducercablethroughit.

Makesurethattherearenospatter,sharpedgesorprotrudingobjectsthatcandamage

thetransducercables.Ifacableisdamaged,andpenetratedbywater,thetransducer

maybedamagedbeyondrepair.

Procedure

1Basedonthevesseldrawings,thephysicalpropertiesofthedecksandbulkheads,

andthephysicallocationsoftheWBTandthetransducer,designthesteelconduit.

Thesteelconduitmustpreferablybestraight.Starttheconduitimmediately

abovethetransducer,andterminateitwellabovethewaterline.Ifyoumust

introducebendsonthesteelconduit,taketheminimumcablebendingradiusinto

consideration.

2Manufacturethesteelconduitaccordingtotherelevantproductionstandards.

3Mountthesteelconduit.

InstallingtheEA440hardwareunits

Loading...

Loading...