46

392616/B

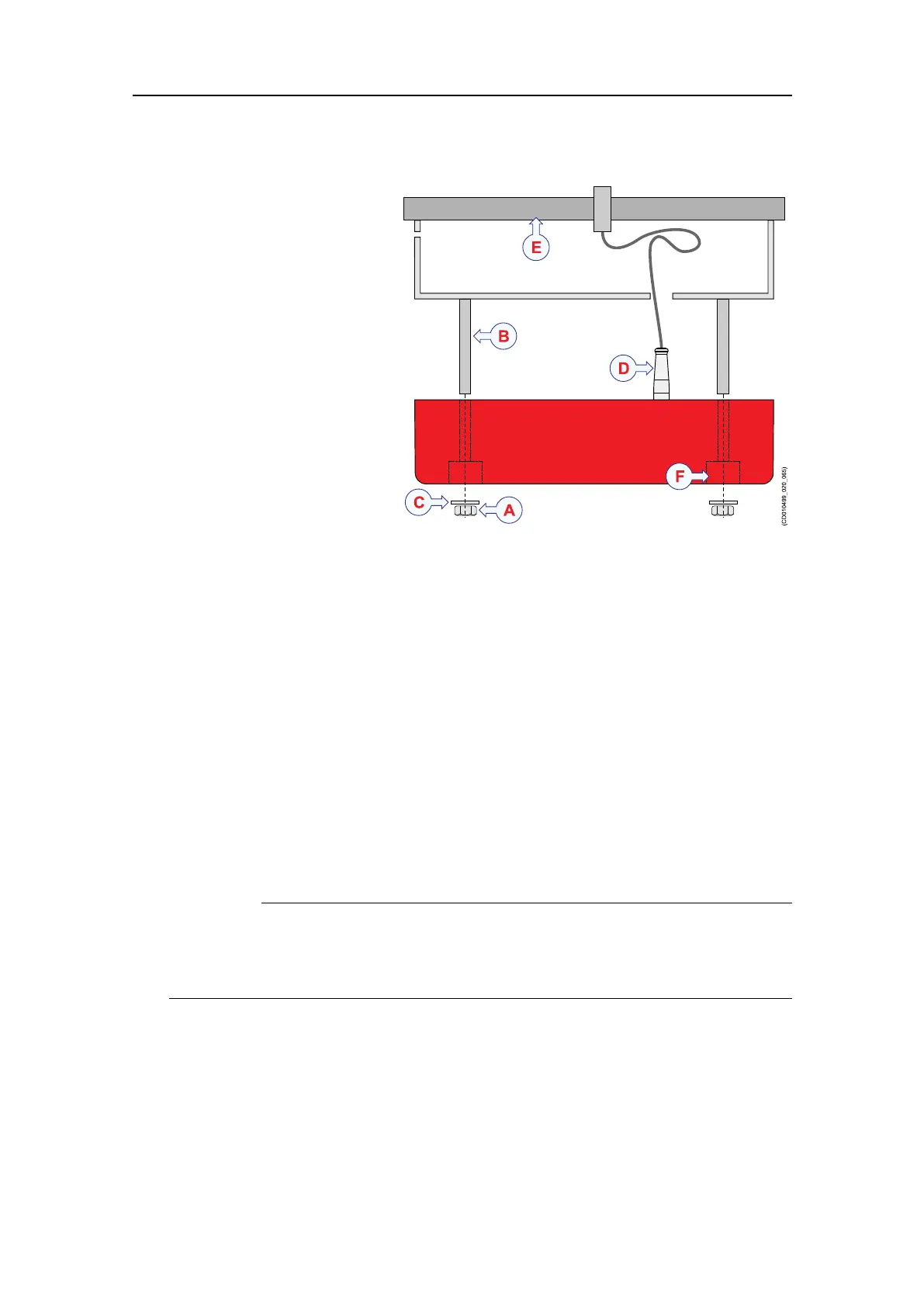

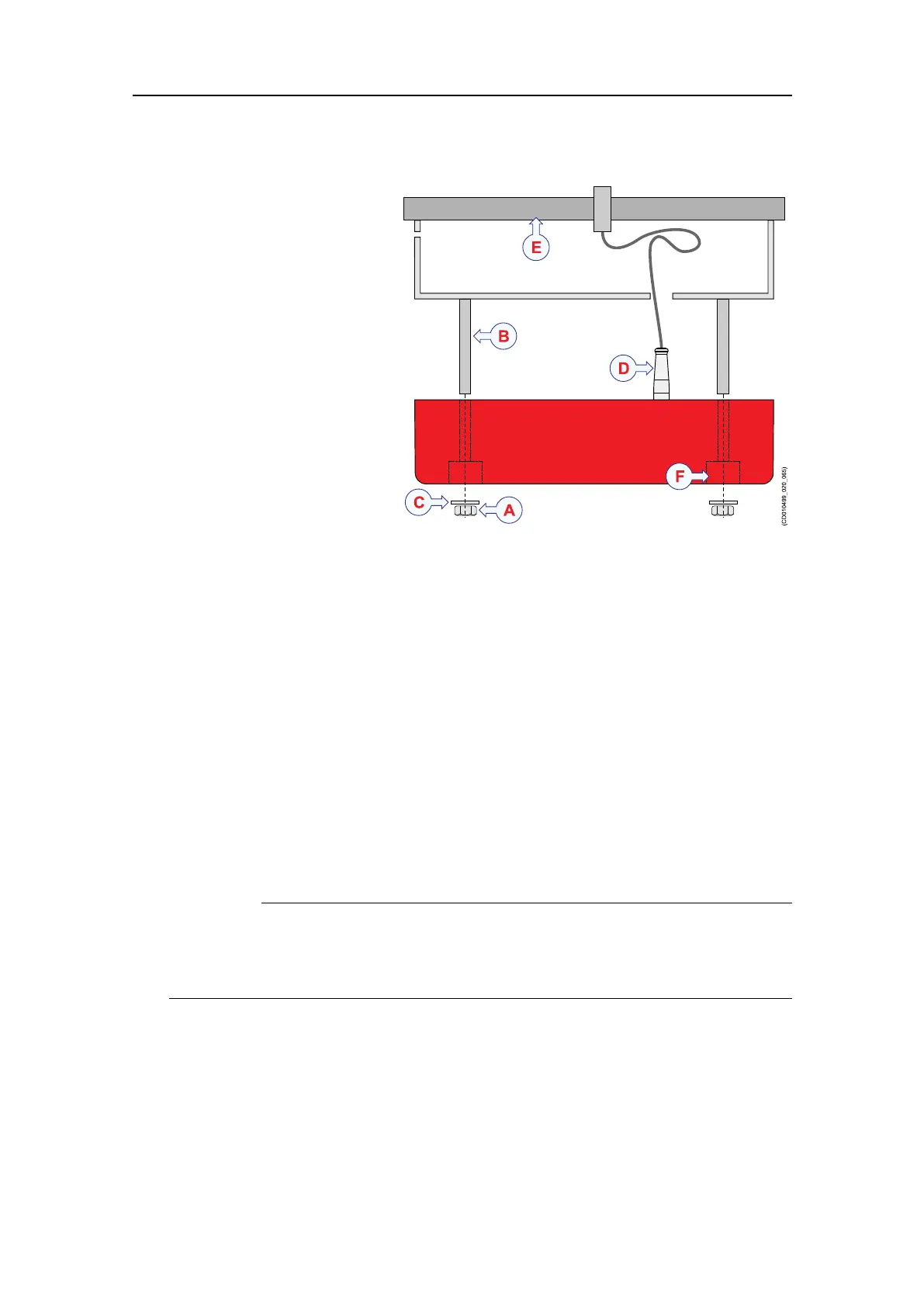

1Nut

2Threadedrodwithsuitable

diameterandlength,

weldedtothebottomof

thefairing

3Washer

4Transducercable

5Hull

6Fillwithsuitablelling

compound(putty)to

reduceownoise

Procedure

1Liftthetransducerupinto

islocation,andalignthe

holesonthetransducer

withthethreadedrodsweldedtothefairing.

Observethedirectionofthetransducer.The"forward"markingmustpointtowards

thebowofthevessel!

2Pushthetransducerinplace.

3Fastenthetwonutsontheendofeachthreadedrod.

UseLoctite290tosecurethebolts.

4Fillthetwoboltholesinthetransducerwithasuitablellingcompound(putty),

andsmoothoutthesurfaceofthetransducerface.

Anyobstructions,cracks,dentsorunevennessonthetransducerfacemaycause

ownoise.

5Whenthetransducerhasbeenfastened,inspecttheplatingaroundthetransducer

face.

Important

Makesurethatthesurfaceofthetransducerface,aswellastheplatingandputty

aroundthetransducerisasevenandsmoothaspossible.Obstructionsonthese

surfaceswillcreateproblemswithturbulentow,andmaycausenoise.

6Ifrequired,allowtherelevantmaritimeauthorityand/orclassicationsocietyto

inspectandapprovethetransducerinstallation.

EA440Installationmanual

Loading...

Loading...