IX - 14

Maintenance

9.3.5 Tyres

• Repairs to the tyres should be carried out by trained personnel only using the right

tools.

• Park the round baler on firm, level ground. Place wheel chocks under the tyres to

prevent unintended rolling.

• Regularly check that wheel nuts are properly seated and tighten if necessary!

• Do not stand in front of the tyre when inflating it with compressed air. The tyre could

burst if too much pressure builds up inside. Risk of injury!

• Check the tyre pressure at regular intervals.

9.3.6 Drawbar

• Tighten the bolts after the first 10 operating hours.

• Check the bolts every 50 operating hours.

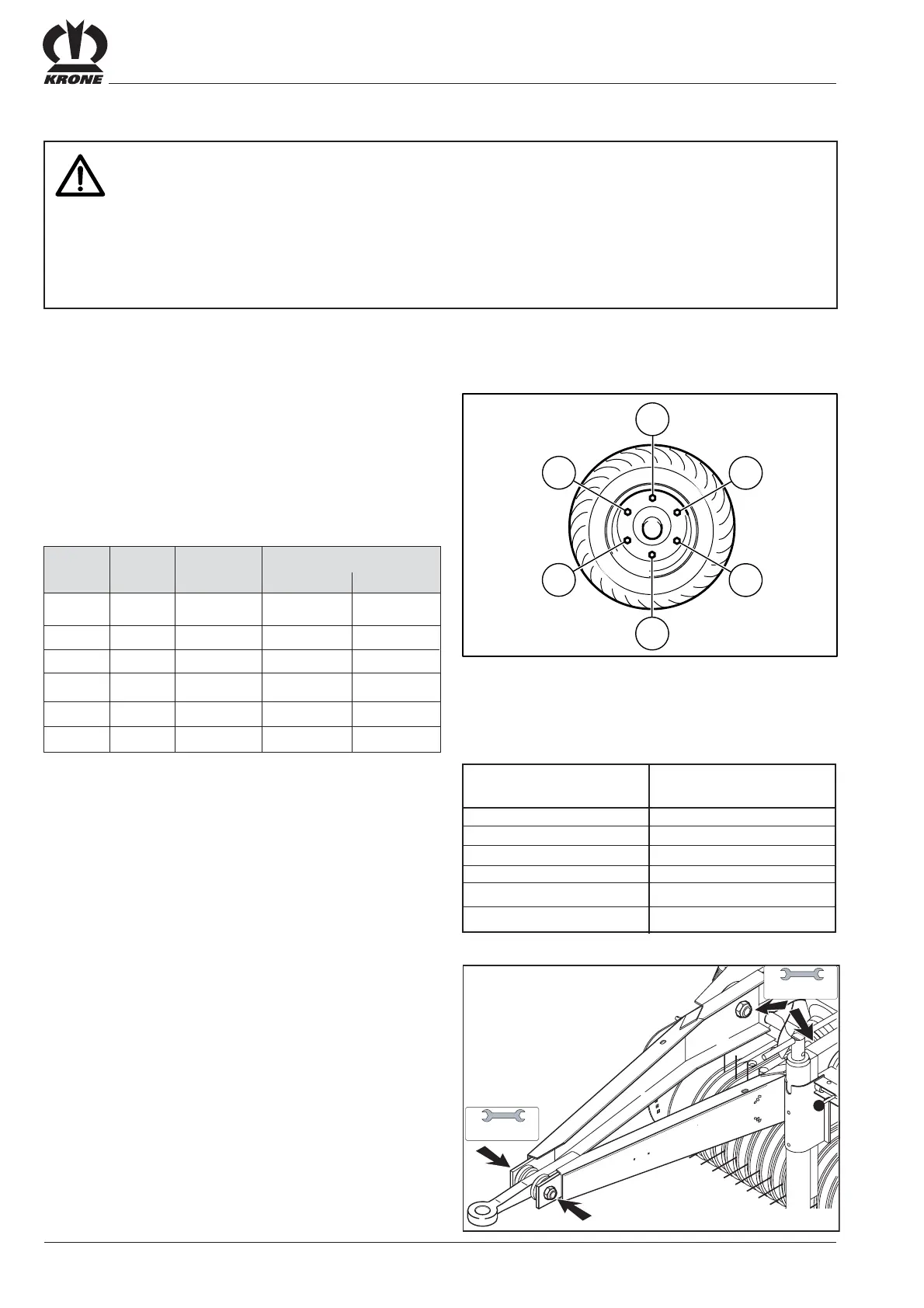

Always slacken and tighten the wheel nuts in the

sequence shown in the diagram at right.

Check the wheel nuts 10 operating hours after mounting

and tighten if necessary.

After this, check that the wheel nuts are properly seated

every 50 operating hours.

Check the tyre pressure at regular intervals and reinflate

if necessary.

Tyre pressure depends on the size of the tyre.

The required values are listed in the table at right.

11.5/80-15.3/10 PR 4.5

15.0/55-17/10 PR 3.5

19.0/45-17/10 PR 3.0

500/50-17/10 PR 3.0

15 x 6.00-6/4 PR 2.5

type of tyre tyre pressure [bar]

KR-1-131

1

3

5

2

4

6

600/50-22,5 /8 PR 1,5

RP-2-002

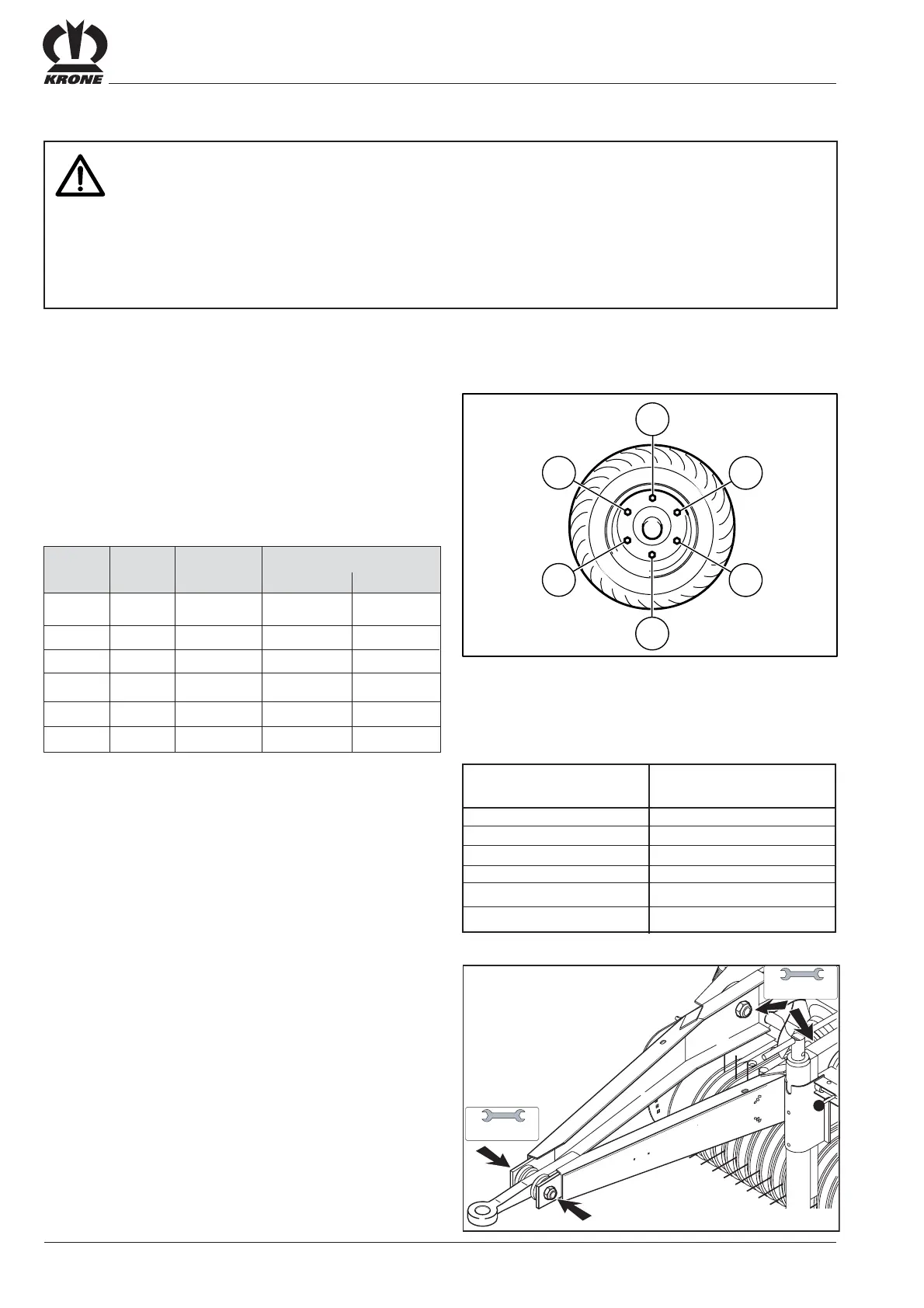

730 Nm

800 Nm

Thread spanner number of max. torque moment

size bolts per

mm hub black galvan.

M 12 x 1,5 19 4/5 95 Nm 95 Nm

M 14 x 1,5 22 5 125 Nm 125 Nm

M 18 x 1,5 24 6 290 Nm 320 Nm

M 20 x 1,5 27/30 8 380 Nm 420 Nm

M 22 x 1,5 32 8/10 510 Nm 560 Nm

M 22 x 2 32 10 460 Nm 505 Nm

Loading...

Loading...