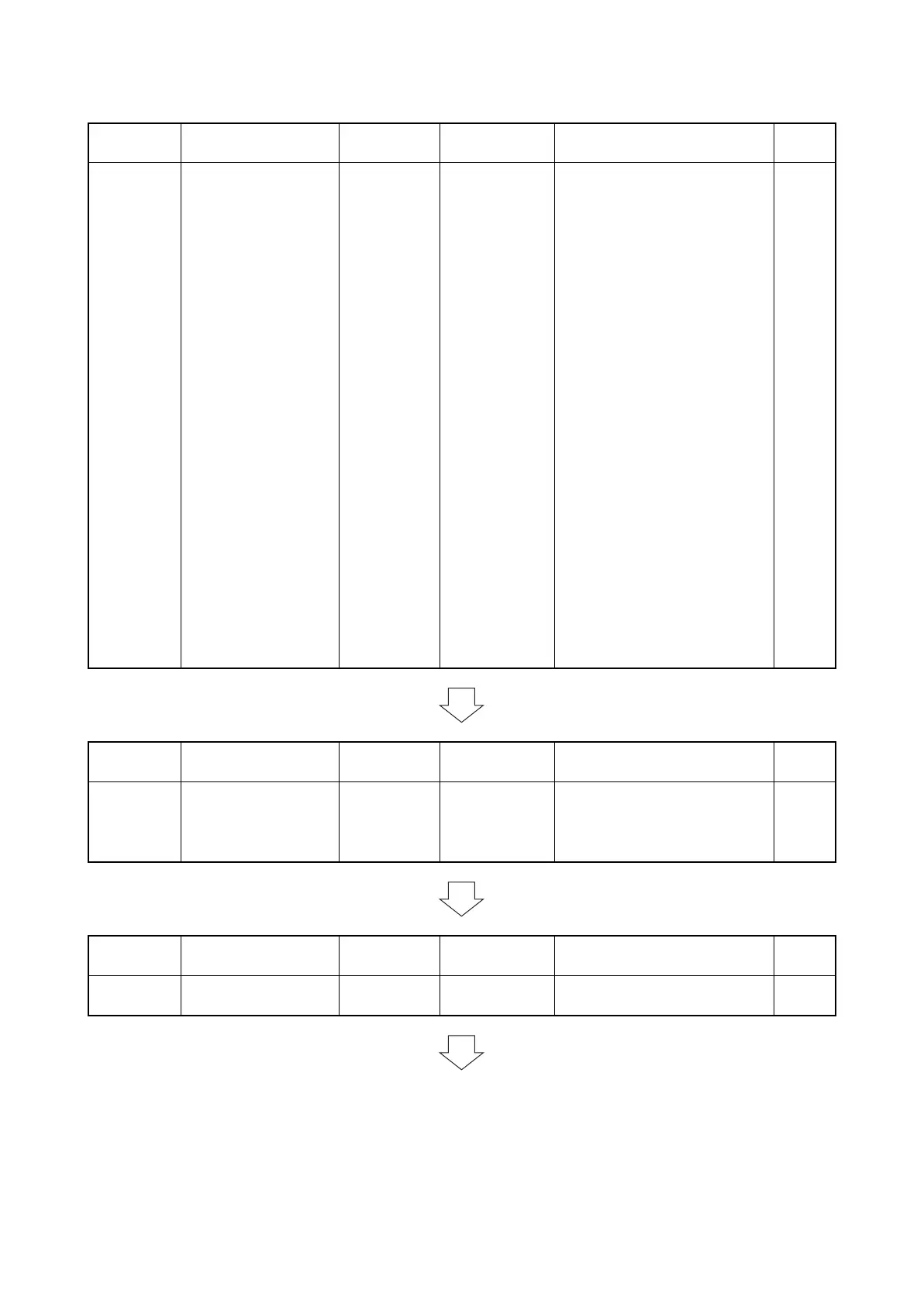

2H0/2HZ-1

2-4-4

Section

Maintenance

part/location

Method

Maintenance

cycle

Points and cautions Page

Optical

section

Laser scanner unit Clean Every service Clean the slit glass with a dry

cloth.

P.1-5-30

Platen Clean Every service Clean with alcohol and then a dry

cloth.

Slit glass Clean Every service Clean with a dry cloth or alcohol

(do not clean with a wet cloth).

Mirror 1 Clean User call Clean with a wet cloth and then a

dry cloth only if vertical black lines

appear on the copy image.

Mirror 2 and mirror 3 Clean User call Clean with a wet cloth and then a

dry cloth only if vertical black lines

appear on the copy image.

Lens Clean User call Clean with a dry cloth only if verti-

cal black lines appear on the copy

image.

Reflector Clean User call Clean with a dry cloth only if verti-

cal black lines appear on the copy

image.

Exposure lamp Check or

replace

User call Replace if an image problem

occurs.

P.1-5-15

Optical rail Check or

Grease

User call Check noise and shifting and then

apply scanner rail grease EM-

50L.

Original size detection

sensor

Check or

clean

User call Clean the sensor emitter and sen-

sor receiver with alcohol or a dry

cloth only if there is a problem.

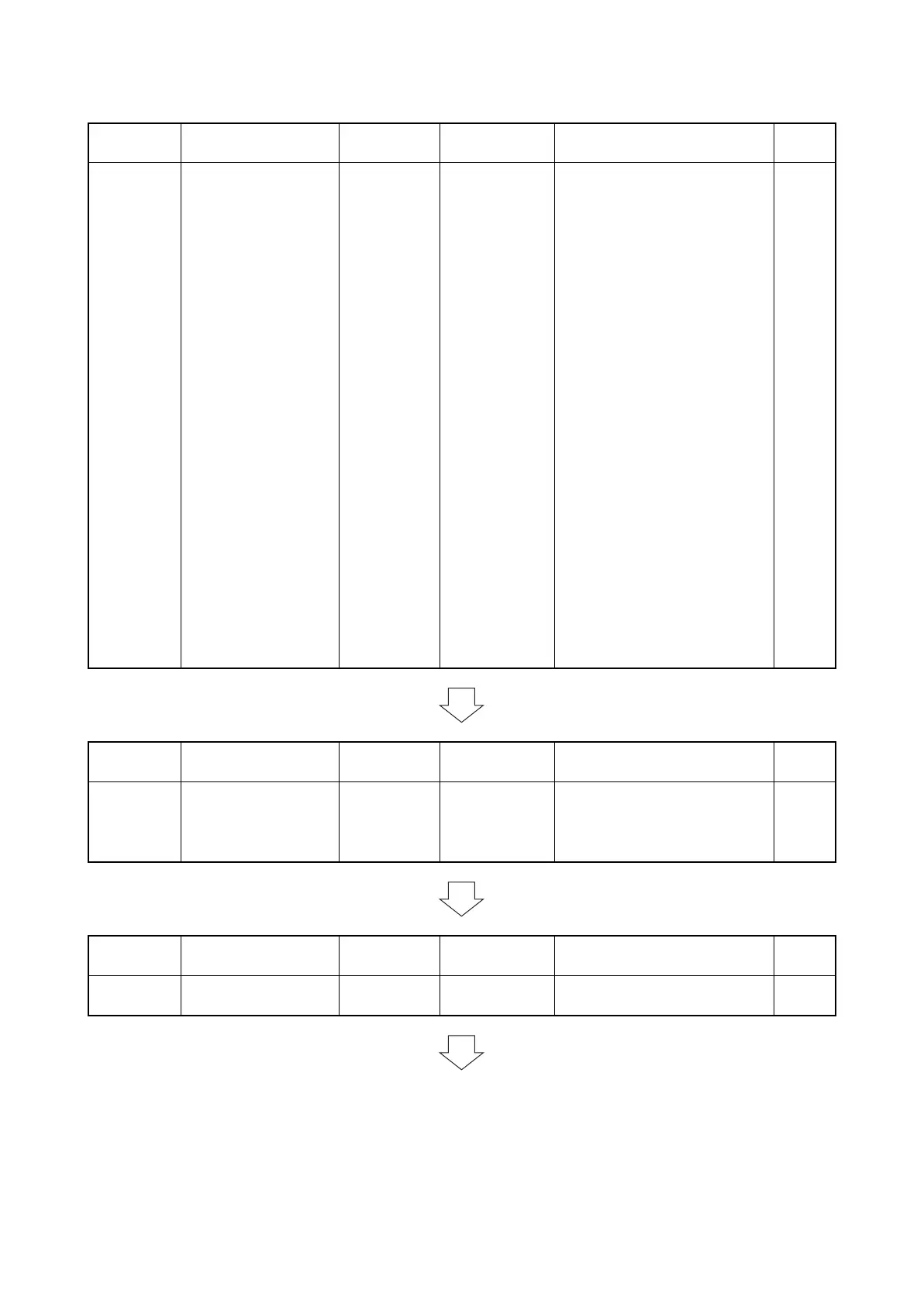

Section

Maintenance

part/location

Method

Maintenance

cycle

Points and cautions Page

Transfer/

separation

section

Transfer roller unit Replace 300K Replace. (Vacuum or clean with a

dry cloth when user call occurs.)

P.1-5-40

Separation electrode Check or

clean

Every service Clean with a cleaning brush.

Section

Maintenance

part/location

Method

Maintenance

cycle

Points and cautions Page

Developing

section

Developing unit Replace 300K Replace. (Check and replace

when user call occurs.)

P.1-5-39

Loading...

Loading...