PLMNL0232 REV. H Effective Date: 01/14/19 22 FiberCUT

®

2D Operation Manual

0

1

2

3

4

5

6

7

8

9

10

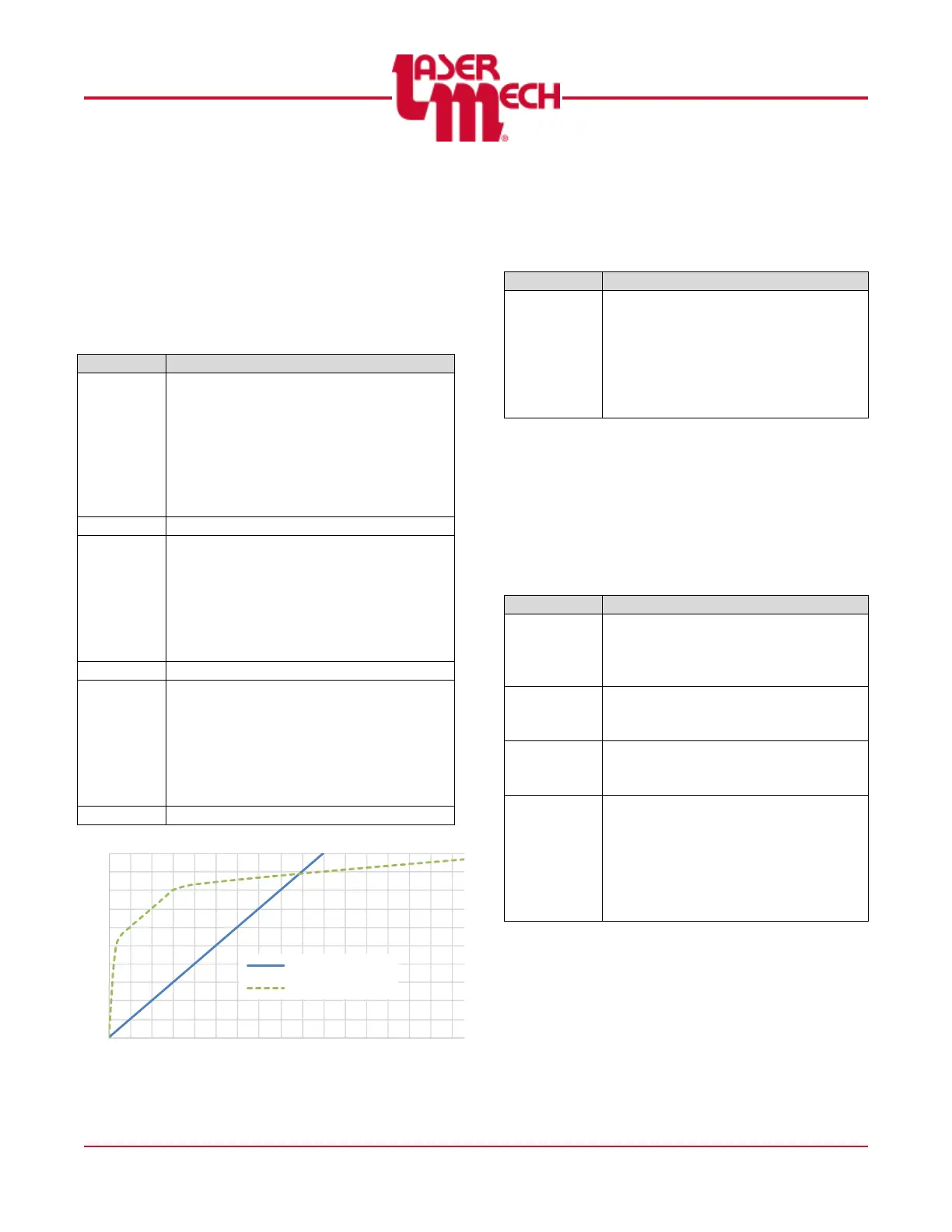

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Volts

Tip Standoff Distance (mm)

HSU Output

HSU out (Linear)

HSU out (Optimized)

3.3.2 Terminal Block Connections

There are 3 analog outputs

(HSU, Aux and Process)

available through the terminal

block connection.

Each analog output signal is

referenced to Ground.

ANALOG OUTPUTS

The HSU output signal (0-10V)

indicates the standoff distance of the

tip and the part.

In general two types of outputs

available; linear and optimized.

Additional output curves may be added

to accommodate customer

requirements.

The Auxiliary Output is a user-defined

signal (0-10V) set using FiberCUT

®

2D

Monitor or the Industrial Ethernet

interface.

~ This output is scaled linearly from 0

to 30mm, 500mbar, or 100°C

depending on the assigned function.

The Process Monitor signal (0-10V)

indicates the status of the laser cutting

process.

~ Interpretation requires significant

processing with the user’s machine to

determine pierce through and loss of

cut values.

Figure 23

There is one analog input

(Lens In) available through the

terminal block.

ANALOG INPUT

The Lens In signal (0-10V) is used

to specify the target position of the

lens.

The input is scaled linearly from 0-

30mm from the Home position.

Actual travel is limited to

27.5 mm.

There are 3 digital outputs

(Ready, Touch and In Pos)

available through the terminal

block connection.

Each of these outputs is a

solid-state relay connected

to Out Com when active.

DIGITAL OUTPUTS

The Ready output indicates that the

head is communicating, lens is in

position and HSU is operating with

no fault conditions.

The Touch output indicates that the

tip has contacted the part or

another conductive surface.

The In Position output indicates that

the lens has reached the

commanded position.

The Output Common allows the

user to configure the outputs for

sourcing or sinking.

~ Connect Out Com to 24 V DC for

“sourcing.”

~ Connect Out Com to 0 V DC for

“sinking.”

Loading...

Loading...