101

PCB Settings

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

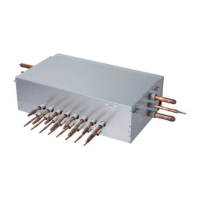

Figure 45: Adjusting the Heat Recovery Unit Addresses.

• Rotary switch SW05M must be set to "0"’ when install-

ing only one heat recovery unit.

• When installing multiple heat recovery units, address

each unit with sequentially increasing numbers start-

ing from "0".

1

2

3

4

1

2

3

4

1

2

3

4

AB AB AB

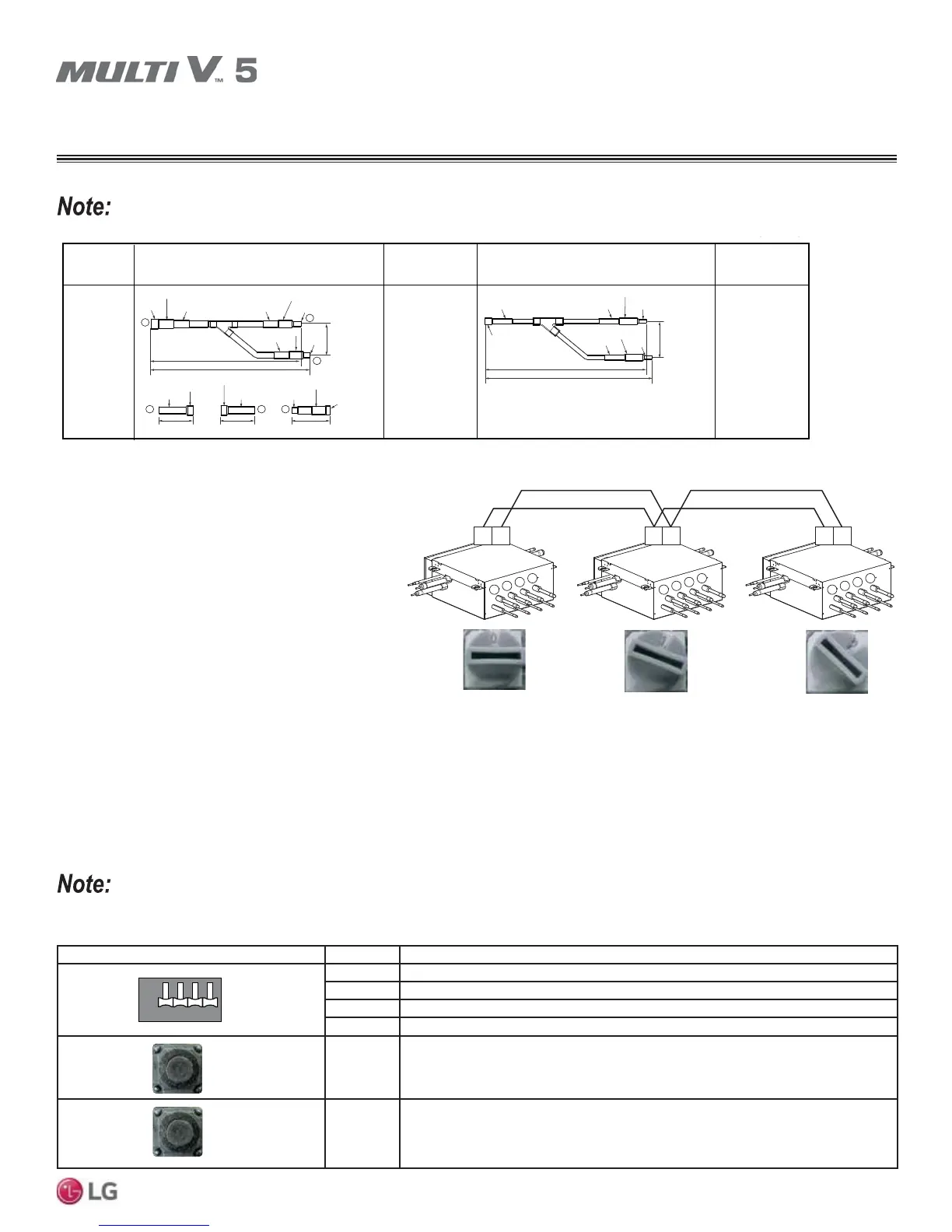

2. SW05M Function (Rotary Switch for Addressing Heat Recovery Units).

6:06:06:0',3DQG7DFW6ZLWFKHVIRU0DQXDO9DOYH

Addressing

Non-zoning (Normal Setting).

• Set the address of the heat recovery unit valve to the central control address of the connected indoor unit.

• SW01M: Select the valve to address.

• SW03M: Increases the valve address by ten (10).

• SW04M: Increases the valve address by one (1).

Each indoor unit must have a unique, preset central control address (using its wired controller) before manual valve addressing can occur.

PCB Component S/W No. Set Up

No. 1 Manual Addressing Valve No. 1

No. 2 Manual Addressing Valve No. 2

No. 3 Manual Addressing Valve No. 3

No. 4 Manual Addressing Valve No. 4

SW03M Increases the Valve Address by Ten (10)

SW04M Increases the Valve Address by One (1)

1

12 43

ON

OFF

2

3

4

SW01M

Table 56: Settings for Manual Valve Addressing, Non-Zoning.

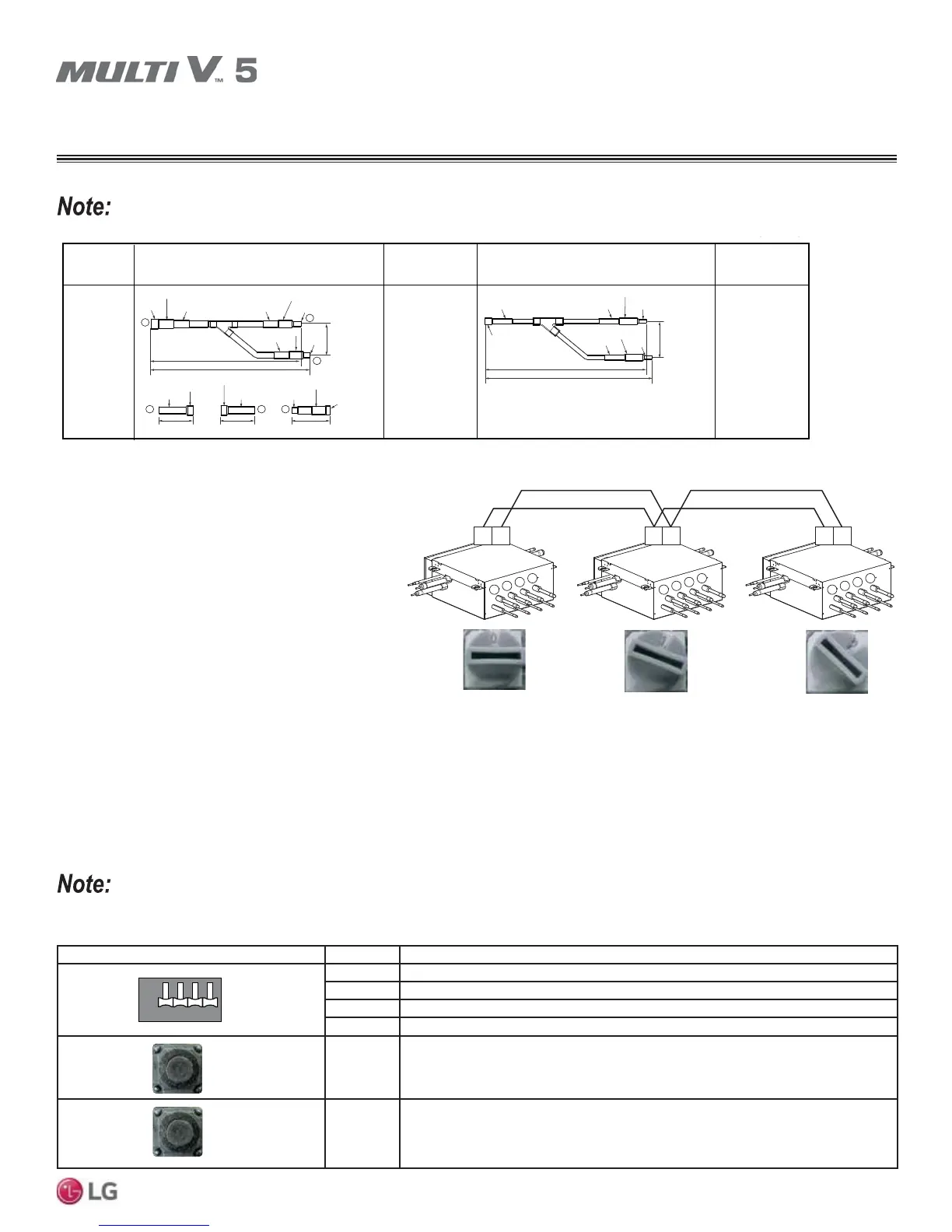

If large capacity indoor units (larger than 54,000 Btu/h) are installed, the Y-branch pipe shown in the table below must be used to twin the ports.

Kit Model

No.

Vapor Pipe Dimensions Liquid Pipe Dimensions

ARBLN03321

16-1/4

15-3/8

I.D. 3/4

I.D. 3/4

I.D. 3/4

I.D. 1/2

I.D. 1/2

2-3/4

I.D. 5/8

I.D. 5/8

I.D. 1

I.D. 1

O.D. 1

3-3/16

4-3/8

3-5/16

2

3

3

O.D. 3/4

O.D. 3/4

12

I.D. 7/8

I.D. 7/8

I.D. 7/8

I.D. 1-1/8

1

I.D. 1/2

I.D. 1/2

I.D. 1/2

13-1/16

12-5/8

I.D. 1/4

I.D. 1/4

I.D. 3/8

I.D. 3/8

I.D. 3/8

2-15/16

Vapor Pipe

Model No.

Liquid Pipe

Model No.

AJR54072902

AJR54072906

HEAT RECOVERY UNIT SETTINGS

Loading...

Loading...