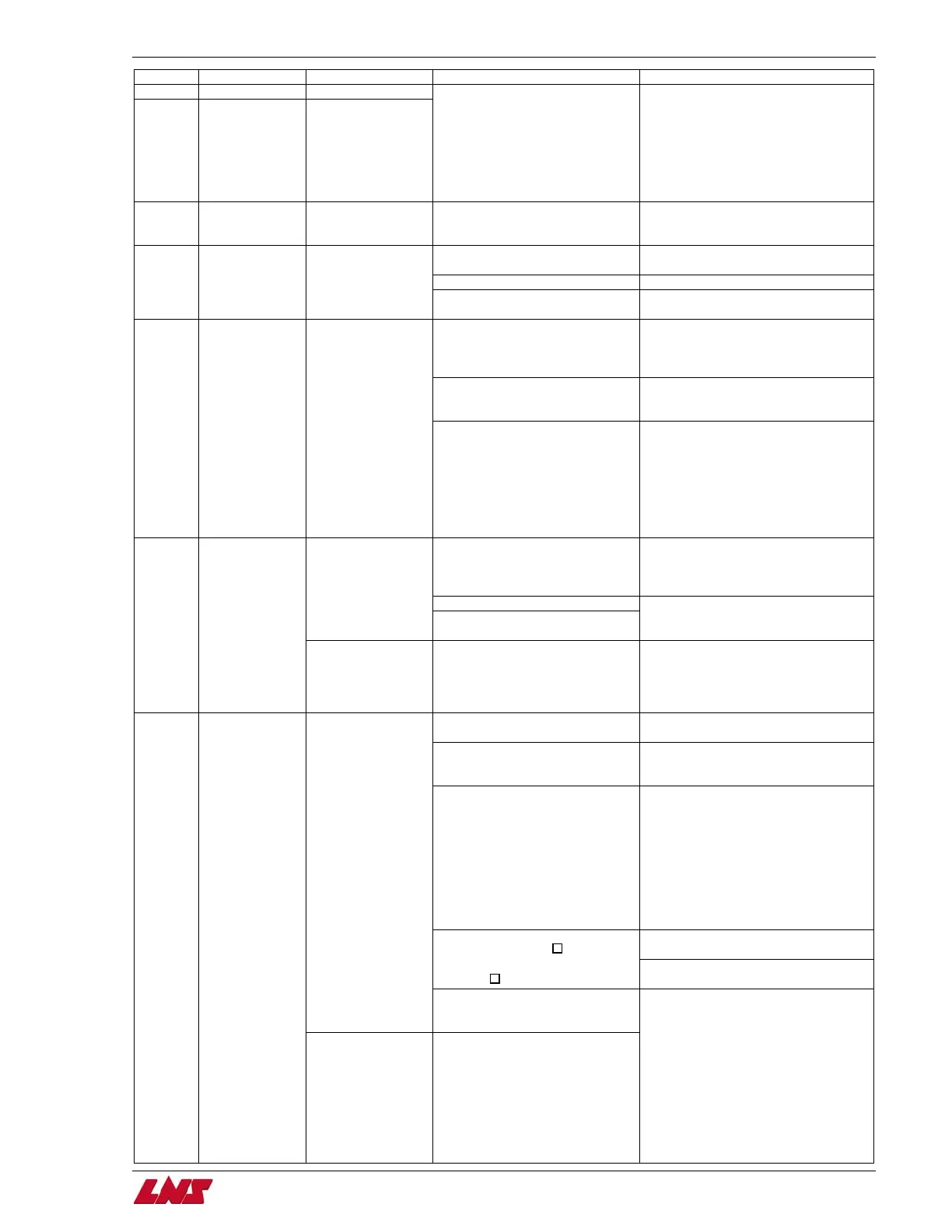

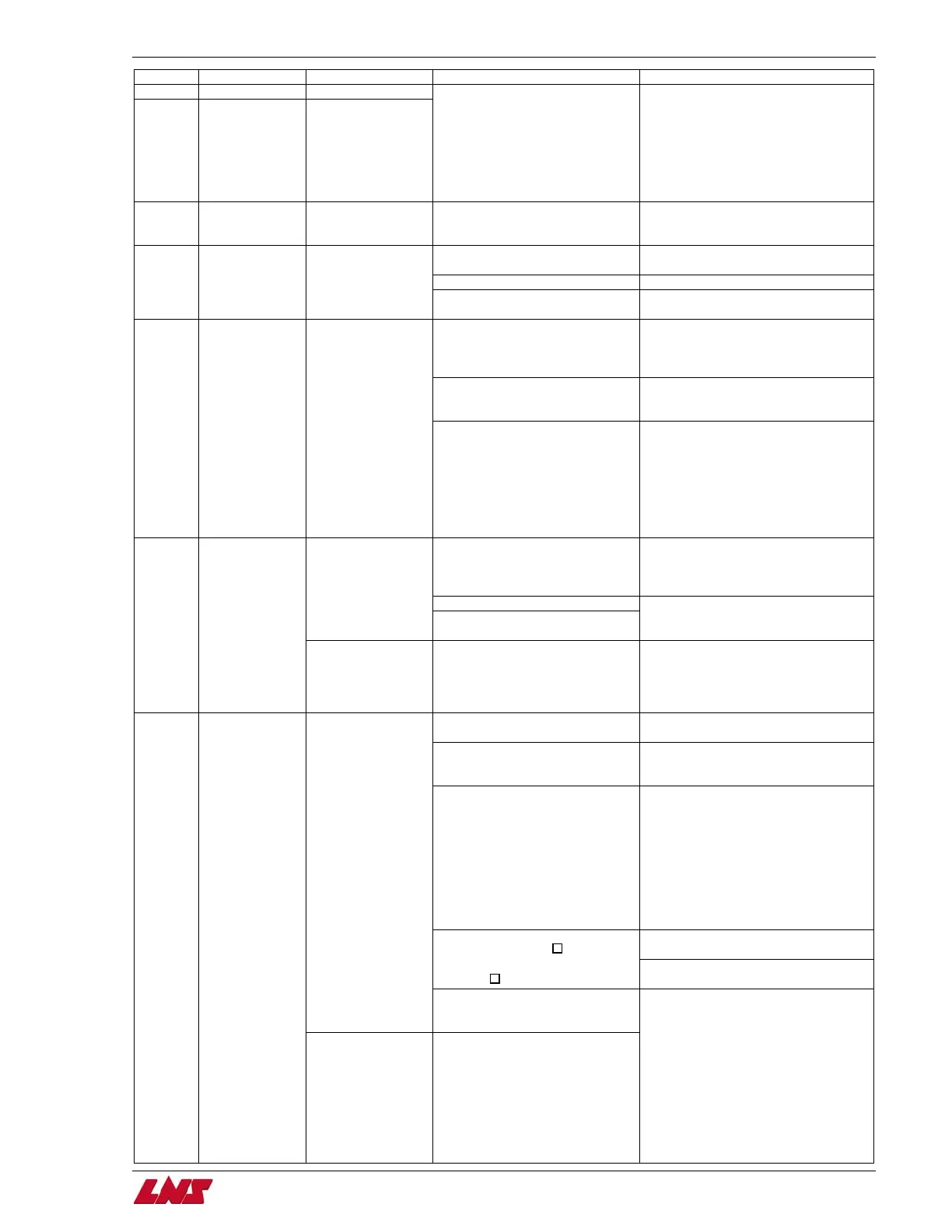

Chapter 1: Alarms

QUICK SIX

1-39

Display Name Definition Cause Action

AL.17 Board error CPU/parts fault

AL.19 Memory error 3 ROM memory fault

Faulty parts in the servo amplifier

Checking method

Alarm (A.17 or A.18) occurs if

power is switched on after

disconnection of all cables but the

control circuit power supply

cables.

Change the servo amplifier.

AL.1A Motor

combination

error

Wrong combination

of servo amplifier

and servo motor.

Wrong combination of servo

amplifier and servo motor

connected.

Use correct combination.

1. Encoder connector (CN2)

disconnected.

Connect correctly.

2. Encoder fault Change the servo motor.

AL.20 Encoder error 2 Communication

error occurred

between encoder

and servo amplifier.

3. Encoder cable faulty(wire

breakage or shorted)

Repair or change the cable.

1. Power input wires and servo

motor output wires are in contact

at main circuit terminal block

(TE1).

Connect correctly.

2. Sheathes of servo motor power

cables deteriorated, resulting in

ground fault.

Change the cable.

AL.24 Main circuit

error

Ground fault

occurred at the

servomotor outputs

(U, V and W

phases) of the

servo amplifier.

3. Main circuit of servo amplifier

failed.

Checking method

AL.24 occurs if the servo is

switched on after disconnecting

the U, V, and W power cables

from the servo amplifier.

Change the servo amplifier.

1. Reduced voltage of super

capacitor in encoder

After leaving the alarm occurring for a

few minutes, switch power off, then on

again. Always make home position

setting again.

2. Battery voltage low

Absolute position

data in error

3. Battery cable or battery is

faulty.

Change battery.

Always make home position setting

again.

AL.25 Absolute

position erase

Power was

switched on for the

first time in the

absolute position

detection system.

4. Super capacitor of the absolute

position encoder is not charged

After leaving the alarm occurring for a

few minutes, switch power off, then on

again. Always make home position

setting again.

1. Wrong setting of parameter No.

0

Set correctly.

2. Built-in regenerative brake

resistor or regenerative brake

option is not connected.

Connect correctly

3. High-duty operation or

continuous regenerative operation

caused the permissible

regenerative power of the

regenerative brake option to be

exceeded.

Checking method

Call the status display and check

the regenerative load ratio.

1. Reduce the frequency of positioning.

2. Use the regenerative brake option of

larger capacity.

3. Reduce the load.

Review power supply 4. Power supply voltage is

abnormal. MR-J2S- CP:260V or

more

MR-J2S- CP1:135V or more

Change servo amplifier or regenerative

brake option.

Permissible

regenerative power

of the built-in

regenerative brake

resistor or

regenerative brake

option is exceeded.

5. Built-in regenerative brake

resistor or regenerative brake

option faulty.

AL.30 Regenerative

alarm

Regenerative

transistor fault

6. Regenerative transistor faulty.

Checking method

1) The regenerative brake option

has overheated abnormally.

2) The alarm occurs even after

removal of the built-in

regenerative brake resistor or

regenerative brake option.

Change the servo amplifier.

Loading...

Loading...