ZENIT

65

DIAGNOSIS

Diagnosis

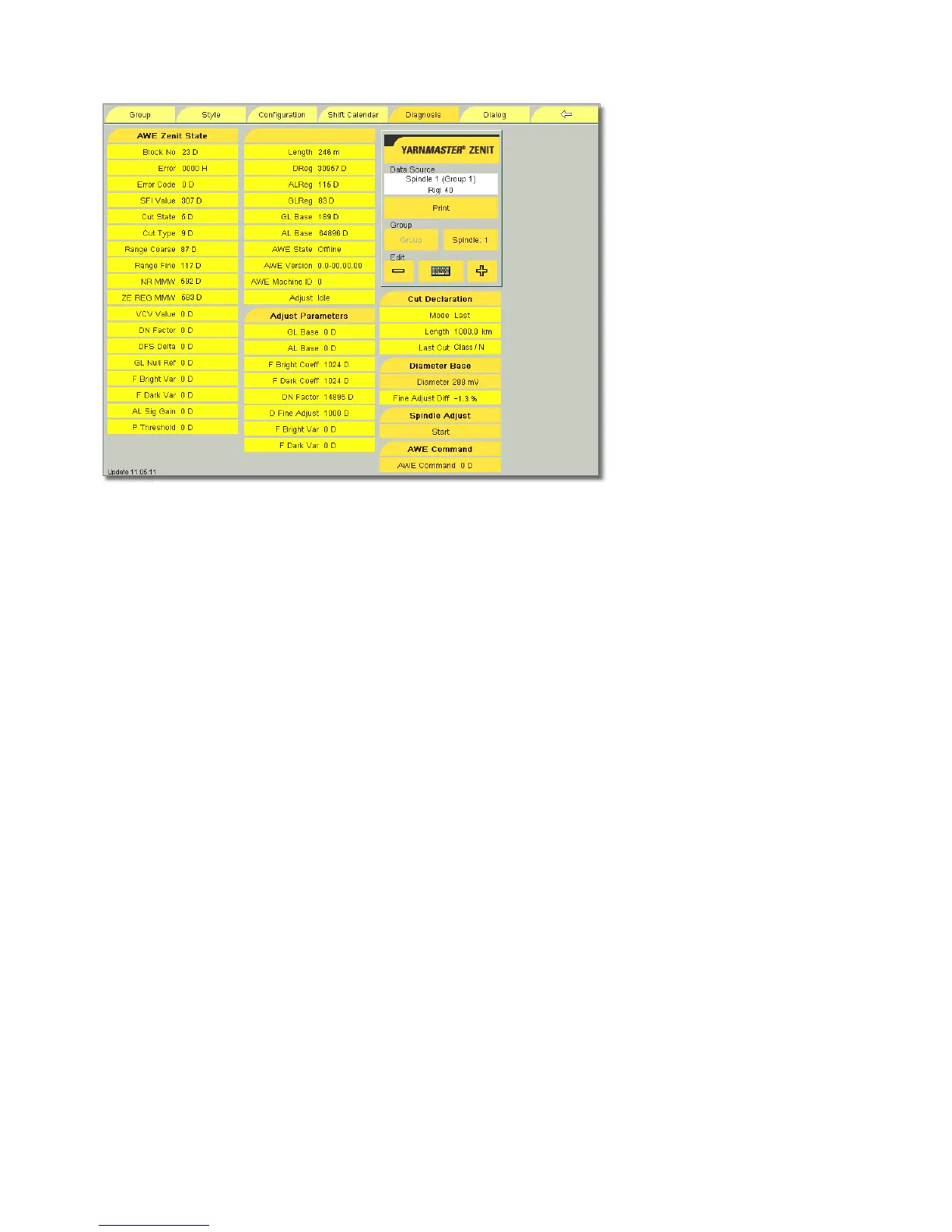

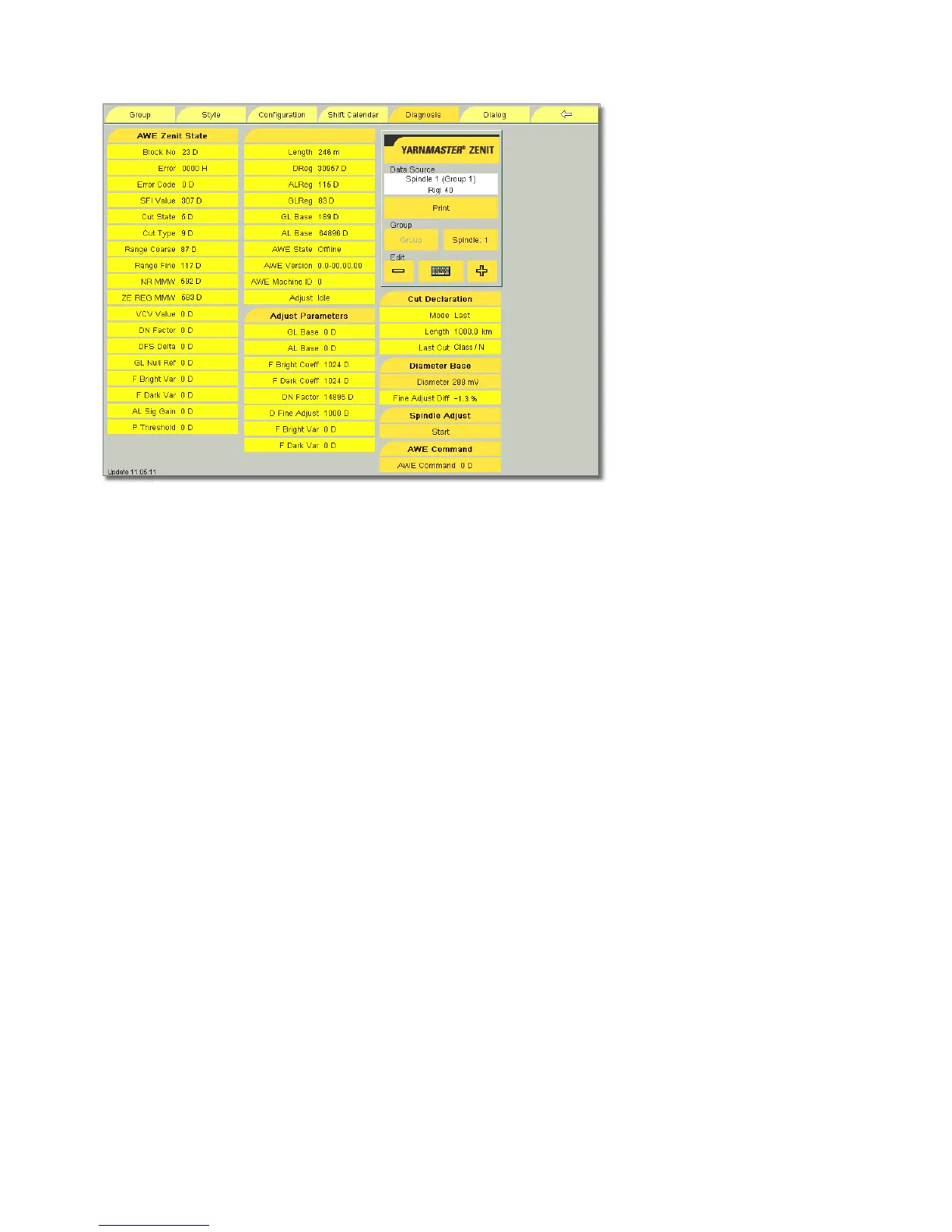

AWE Zenit State / Adjust Parameters

AWE Command

This information is used exclusively by the service techni-

cians or trained personnel.

!

Incorrect commands can have severe consequences

for the clearer function!

Diameter Base (Spindle)

In Diameter Base, the determined value is automatically dis-

played after an Adjust process. This value corresponds nor-

mally to the average yarn signal of the spindle.

!

This value should be changed manually only in special

cases!

Fine Adjust Diff

Deviation in percent of the yarn diameter averaged over all

spindles from the basic value (adjustment value).

!

A continuous deviation of this indication means a

yarn count deviation!

Spindle Adjust

When replacing an evaluation unit (AWE) or a sensing head

(TK), a reset must be performed on the AWE. Additionally,

an Spindle Adjust must always be performed on this winding

unit. The yarn reference value of the first 80 m yarn is mea-

sured and stored.

•

Tap the Start button

•

Start the respective spindle.

The display on the button switches to Stop. If the adjustment

was successfully completed, Start is displayed again.

!

The wound yarn (80 m) could still have faults since

the clearing is not active during the Adjust process.

Cut Declaration

See Monitoring Data.

Loading...

Loading...