Introduction 9

1. Introduction

1.1 Overview

The GS550 system includes the cabin mounted GS550 radio display and compatible crane

mounted sensors. The GS550 creates a two-way radio network with the sensors to bring required

lift data to the operator. Hoist load, boom and jib angles, boom length, wind speed and pending

two-block can be detected and indicated to the operator in real time. Working load radius can be

calculated and compared to a rated capacity chart (if programmed). Furthermore the GS550 can

be programmed to generate warnings, alarms and lockout commands, all triggered by adjustable

thresholds and limits. All these events can be recorded by the data logger with a time and date

stamp. The exact operational function of the GS550 system depends on the sensor configuration

used and the rated capacity charts programmed (where applicable). The GS550 includes an

infrared port to facilitate software and chart updates and data logger downloads using a compatible

personal digital assistant (PDA) or cell phone. Compatible sensors include the GS050 anti-two-

block, the GC series load cells and GS001 series line rider and load pin transmitters, the GS010

angle sensors, the GS011 angle sensor and length transmitter and the GS020 wind speed sensor.

The GS550 system is designed as an operator aide and is in no way a substitute for safe operating

practice

1.2 Version Compatibility (applies for produced manufactured prior to

June 2007)

GS series product with version 2 firmware is not compatible with GS series product with version 1

firmware. For information on upgrading GS series product from version 1 to version 2 firmwares

please contact LSI.

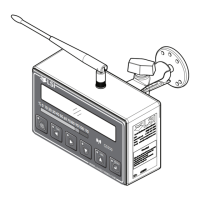

1.3 Start-Up

The GS550 (see Figure 1) must be correctly programmed for the system sensors installed. The

GS550 powers up with several green lights flashing, this indicates that the display is waking up

programmed sensors and creating a radio communication link with each. Once a reliable radio

communication network is established, all green lights will remain lit without flashing.

This process may take up to one minute. The delay is created by the battery management function

and does not affect system security. If an anti-two-block switch detects a pending two-block event,

if a load cell detects a change in load, or if an angle sensor detects a change in angle, the appro-

priate radio link will be established in less than 0.1 seconds. To immediately wake-up a load cell,

lift the hook with a load; to immediately wake up an angle sensor, change the boom angle.

In special conditions of lockout created by a missing sensor, you may press the BYPASS button to

allow the system to work. When rigging the crane, out of normal capacity chart condition could

create annoying alarms, and the display could then be put in ‘rigging mode’. If the rig mode is

enabled in the display, press BYPASS for 10 seconds to activate it. If the rig mode is not available,

contact your LSI representative or LSI technical support (p. 75).

Loading...

Loading...