Technical Specications

22

IDM 510-006-5

English language Operation and maintenance manual

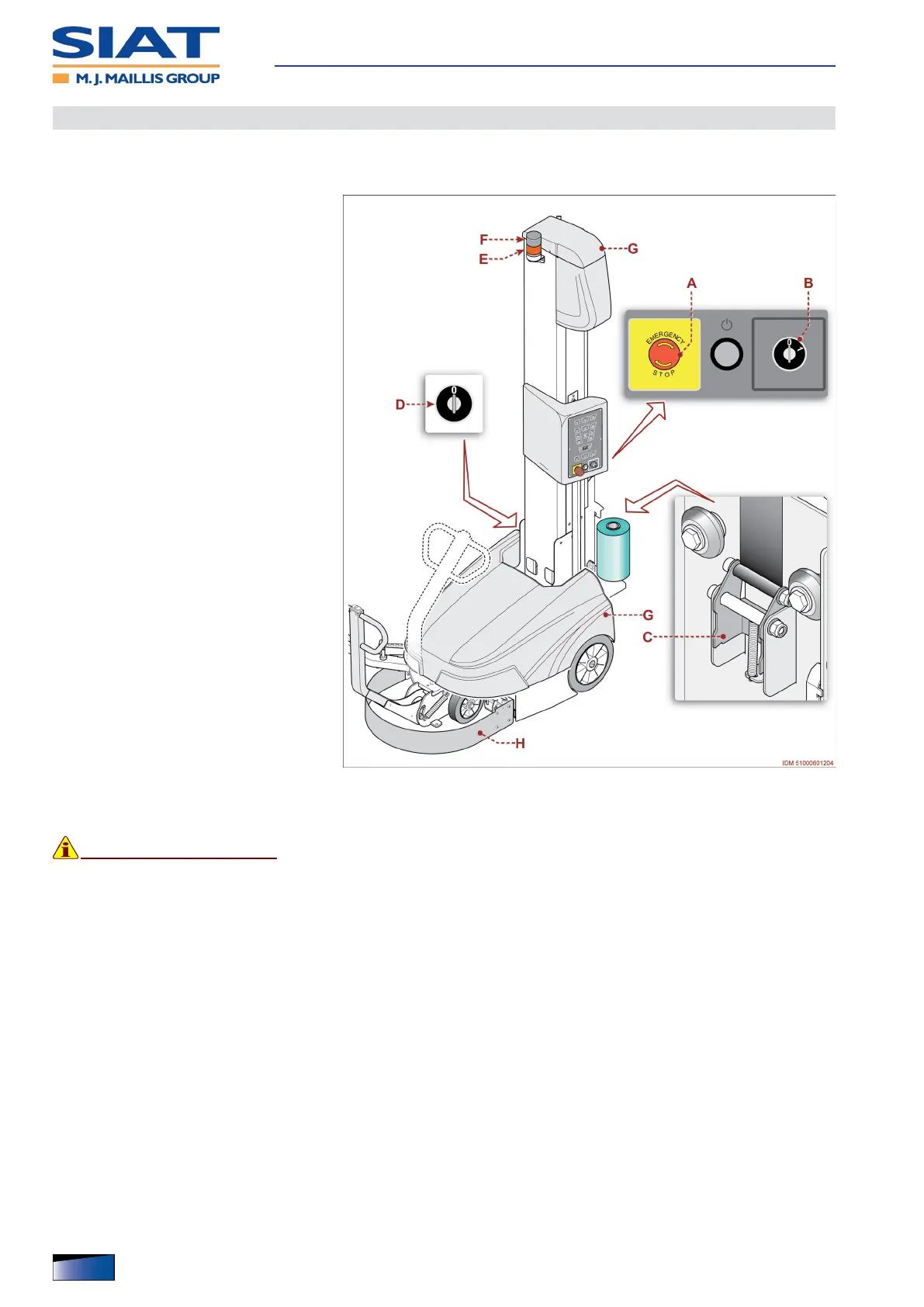

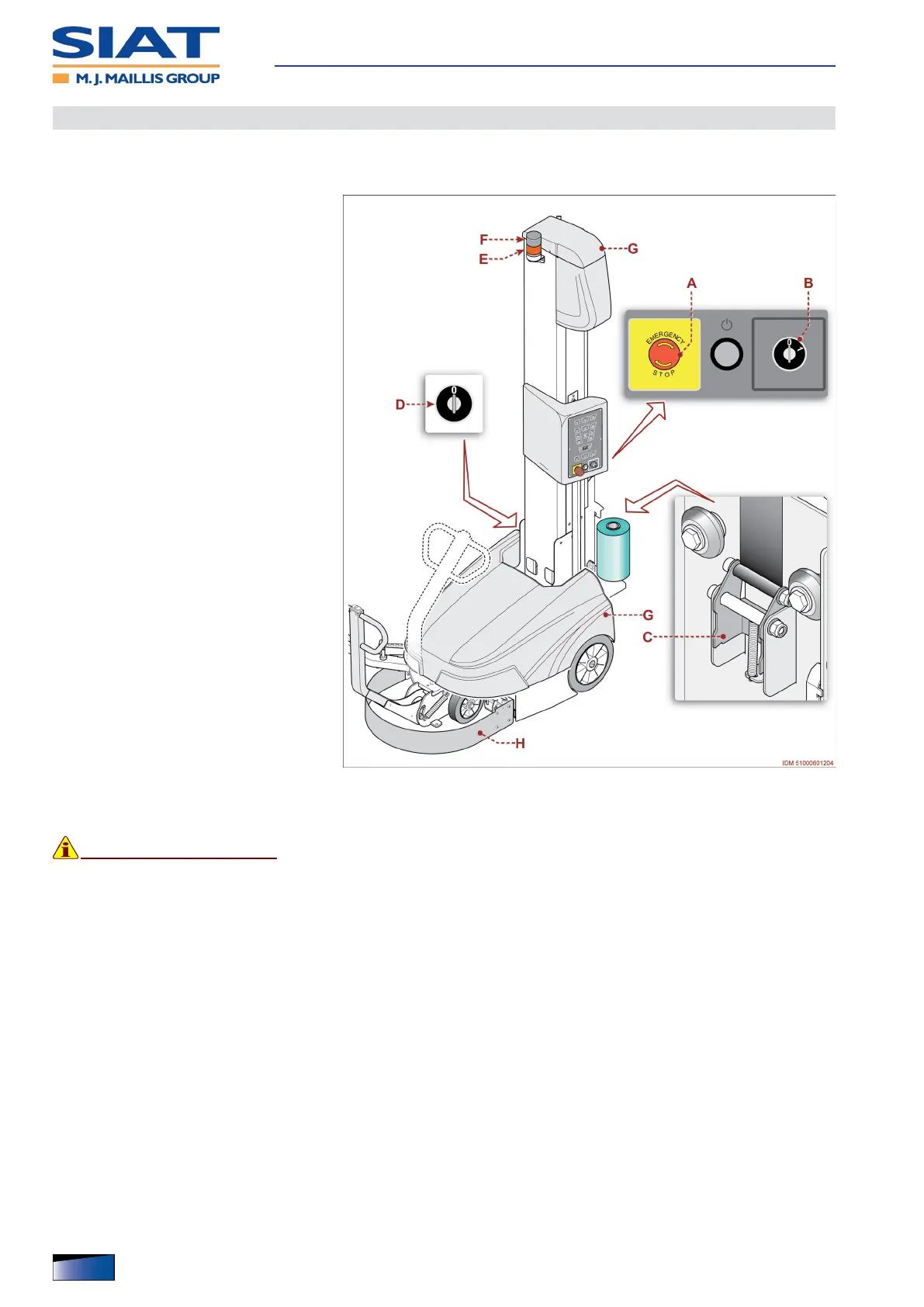

Description of the safety devices

The machine is equipped with safety devices that reduce the risks during the

man-machine interaction.

A) Emergency stop button: safety

control that, in case of an imminent

risk, stops all parts whose function

might constitute a risk.

See “Control description” for further

details.

B) Key selector switch: safety control

that connects and disconnects the

power supply of battery.

C) Fall arrest system: safety device

that prevents the risk of a fall of the

carriage in the event of lifting strap

breaking.

– System is equipped with spring de-

vice that locks reel holding carriage

in its position in case of failure of

belt.

D) Key selector: control to activate and

deactivate brake of the machine in-

feed electric motor.

– The key of control must be hand-

ed over to the maintenance tech-

nician in order to avoid any inter-

ference by non-authorised

personnel.

– When the machine stops and display

shows “b0”, it means that batteries

are completely exhausted.

Important

ONLY the maintenance technician is allowed to release the brake of the electric

motor in order to move the machine to the charge area.

E) Warning light (yellow light): safety device that signals the operating conditions of the

machine.

F) Audible warning device: safety device indicating the wrapping or machine conveying

process with manual control.

G) Fixed guard: safety device that prevents access to the parts whose operation may be

dangerous.

– The device is secured and it can be opened only by means of tools.

– Guard can be removed only when the machine is stopped under safe conditions and

must be installed before starting it.

H) Emergency bumper: safety device that stops the operation in emergency conditions,

in case of collision against an obstacle.

Loading...

Loading...