33

IDM 510-006-5

Use and functioning

English languageOperation and maintenance manual

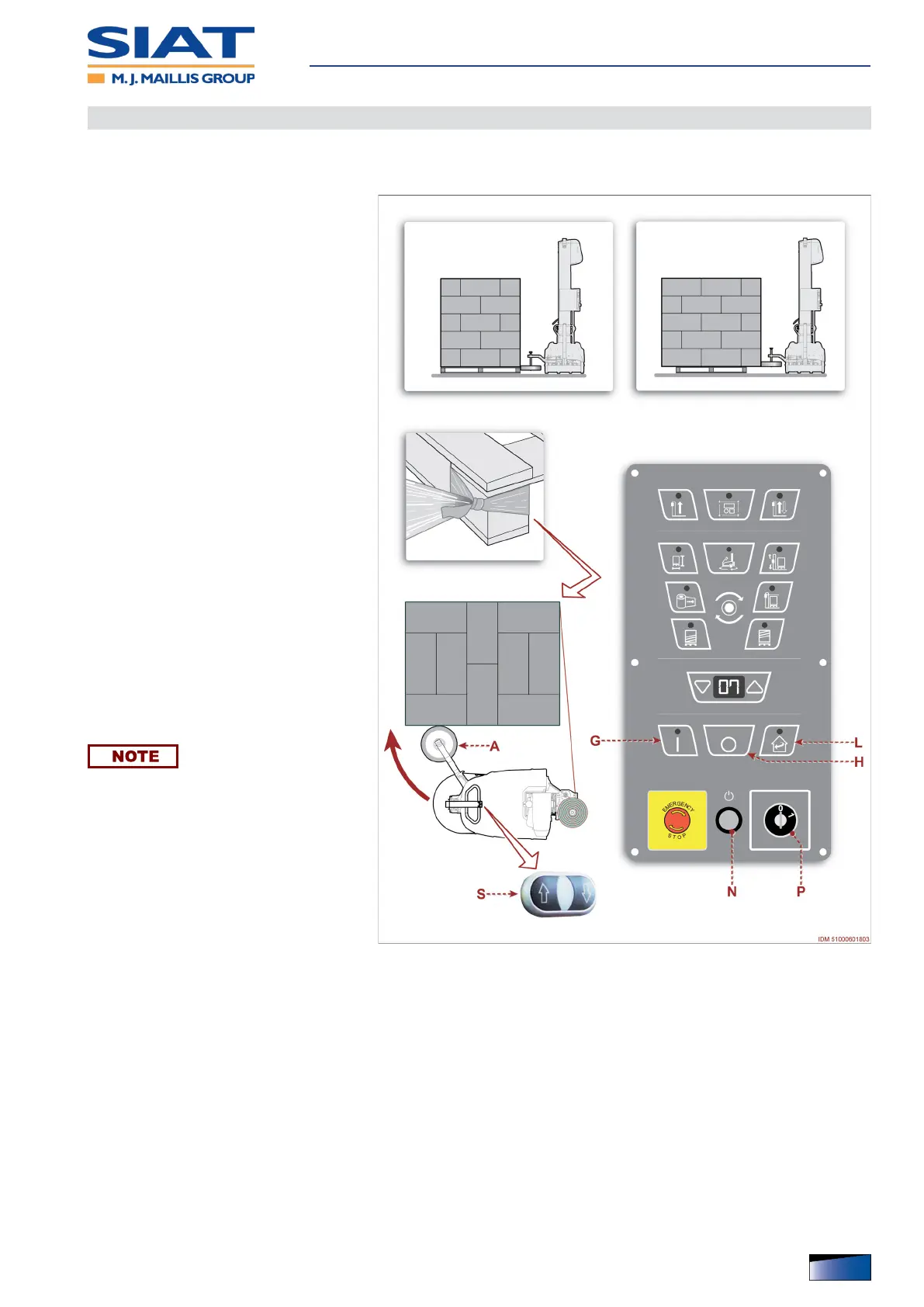

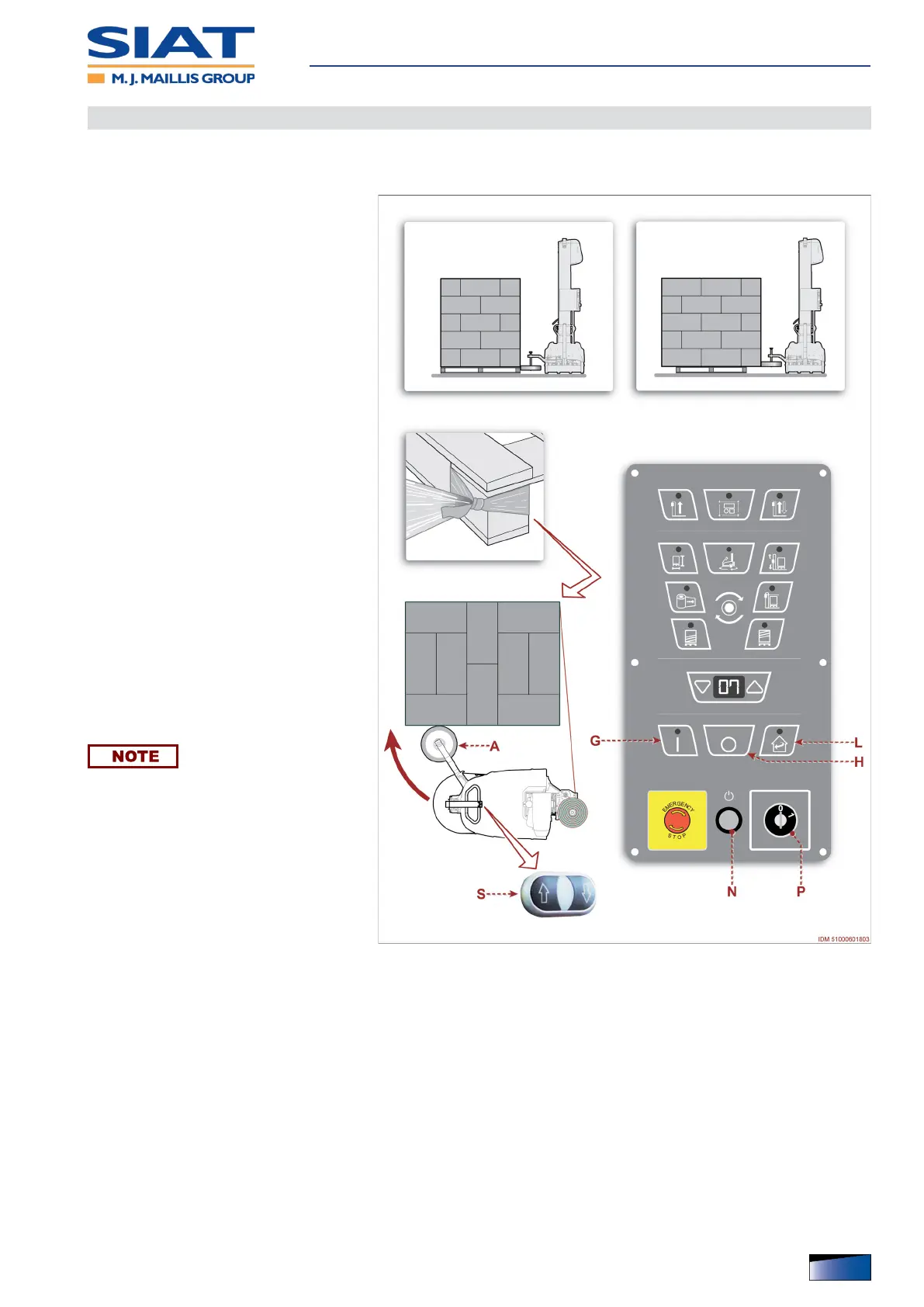

(Single or double) automatic wrapping

The gure shows the points of intervention and the description shows the proce-

dures to be adopted.

1. Check whether the wrapping lm has

the same chemical-physical proper-

ties as that installed in the reel holder

carriage.

– If lm characteristics appear to be

different, consider whether you

should adjust the lm tension.

2. Rotate selector P to position “1”

(ON) in order to activate the battery

power supply.

– The pilot light of button N turns on.

3. Press the push-button N.

– The pilot light of button N turns off.

4. Use the buttons S to lean the roller

feeler A against the load to be

wrapped.

5. Before commissioning, check that

roller feeler is next to the upper sur-

face of the pallet.

– If the pallet is smaller than the load to

be wrapped, roller feeler must be po-

sitioned on the lowest side of the

load.

The support area must be sufciently

regular to allow roller feeler to rotate

properly.

6. Tie the trailing end of the lm to the

base of the product to be wrapped.

7. Select and activate the recipe of in-

terest.

See “Recipe management” for furc-

ther details.

8. Press button G to start the wrapping cycle.

– If the LED of key L is ashing, press key L to move reel holding carriage to its end-of-

cycle position.

– When reel holding carriage is timed, the LED of key L turns off.

– To restart the wrapping cycle, press key G again.

– Audible warning device is activated to warn that the machine is operating.

– The machine stops as previously described, based on the selected type of wrapping.

Loading...

Loading...