Maintenance

46

IDM 510-006-5

English language Operation and maintenance manual

Monthly check of the safety bumper

The check is necessary to verify the efciency of the safety system and to maintain

a suitable efcacy level to prevent unexpected risks.

– The operation must be carried out by the maintenance technician or by person-

nel with suitable competences, skills and knowledge.

– Make sure to full the required requirements in order to work under safe condi-

tions.

Important

The check must be carried out with the machine connected to the power supply, but

NOT MOVING.

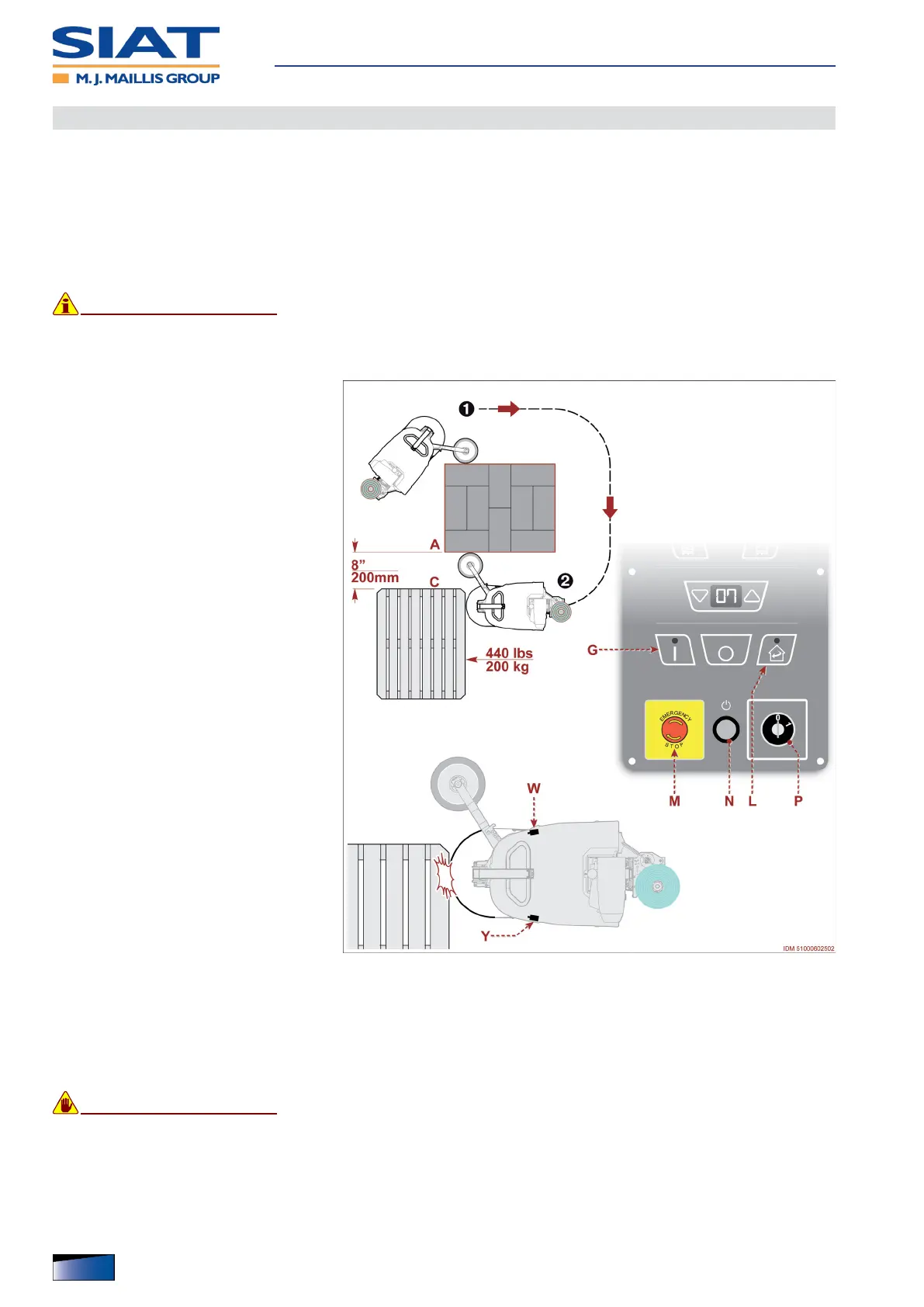

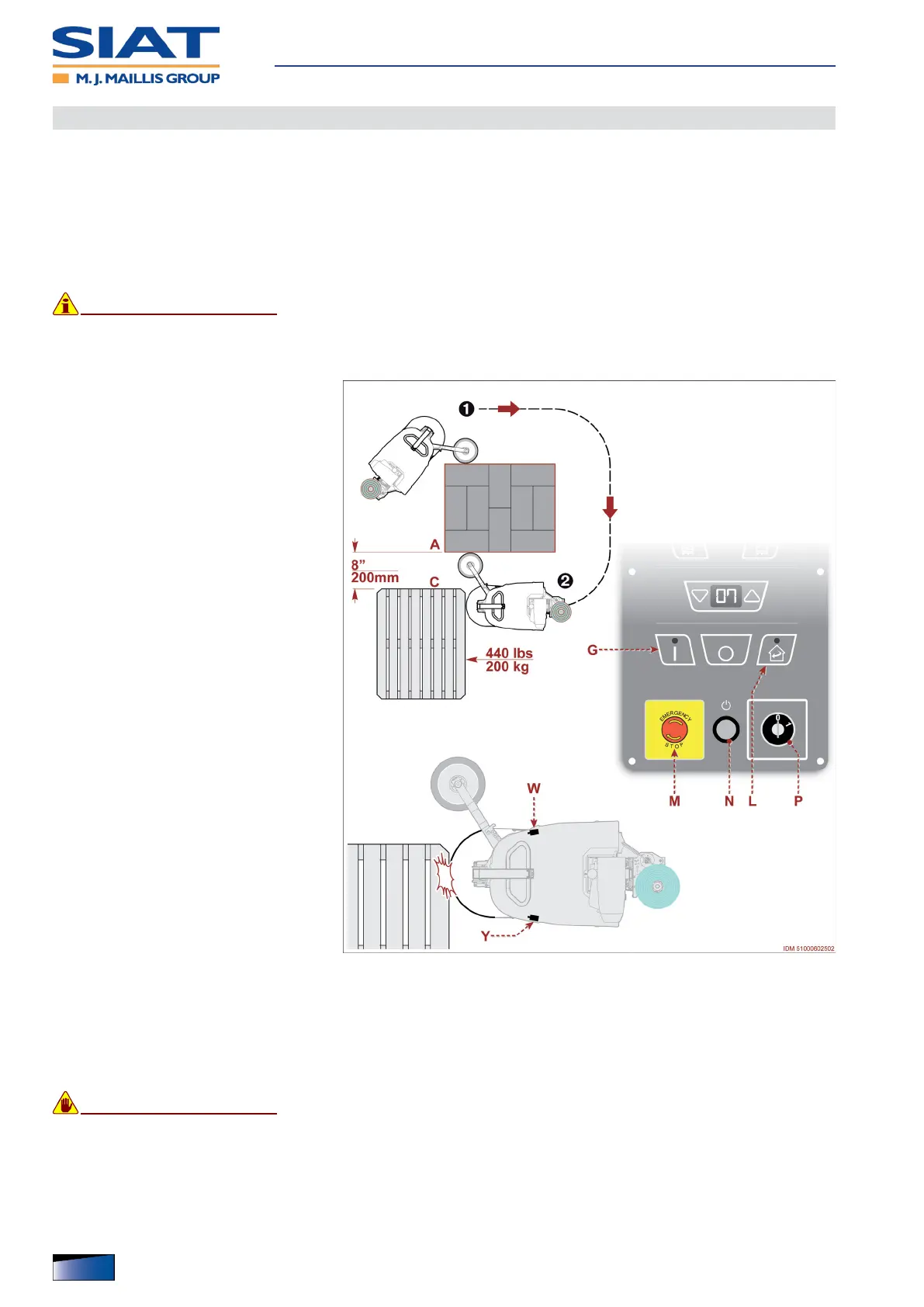

– The gure shows the points of inter-

vention and the description shows

the procedures to be adopted.

1. Rotate selector P to position “1”

(ON) in order to activate the battery

power supply.

2. Press the push-button N.

3. Position the machine in the area A,

next to the load to be wrapped.

4. Position a test load or pallet in posi-

tion C, at the distance and having the

weight that are specied in the im-

age.

5. Adjust the control panel to set the

minimum travelling speed of the ma-

chine.

6. Press button G to start the wrapping

cycle.

– The machine begins to move forward

(audible warning device operating)

until emergency bumper collides

against test pallet.

– Due to collision, the machine must

stop under emergency conditions.

– In case of emergency conditions, the

pilot light of button N is on and audi-

ble warning device is off.

– If the machine does not stop under emergency conditions, one or both microswitches

W-Y are damaged.

The fault can be detected also in case the driving wheel continues rotating.

en

on

Warning

If the machine does not stop, press emergency stop button M.

7. Press the Reset key L.

8. Replace the components, if damaged.

Loading...

Loading...