HYDRAULIC SYSTEM 18000 SERIVCE/MAINTENANCE MANUAL

2-32 Published 12-05-17, Control # 035-23

Charge Pressure Check

See Figure 2-23 and 2-27 for the following procedure.

The charge pressure line of the calibration screen indicates if

any charge pump is not within 275-400 psi (19-27 bar).

Charge pressure should be checked at the following

intervals:

• When a new controller node is installed

• When a pump is replaced

• When a pump control (EDC or PCP) is replaced

• Every 6 months

To check charge pressure, proceed as follows:

1. Start and run engine at low idle

2. Access calibration screen shown below as follows:

a. Turn LIMIT BYPASS switch clockwise and hold.

b. SCROLL UP at least one screen.

c. Continue to scroll up or down until calibration screen

appears.

d. The fourth line of the screen indicates charge

pressure:

- If 0 appears, all charge pumps are okay.

- If any number other than 0 appears, use Table

2-11 to determine which pumps have failed the

test.

Each pump is assigned a number in the binary

system. Outputs that are ON (failed) for any

pump, are added together. To identify the failed

pumps, find the binary number displayed on the

screen in the first column of Table 2-11

. All

shaded boxes to the right of the number

indicate pumps that have failed. Troubleshoot

the particular system to determine the cause of

the fault.

e. Proceed to next procedure, or exit calibration

screen by pressing bottom of CRANE MODE

switch. Cursor (*) will disappear from screen.

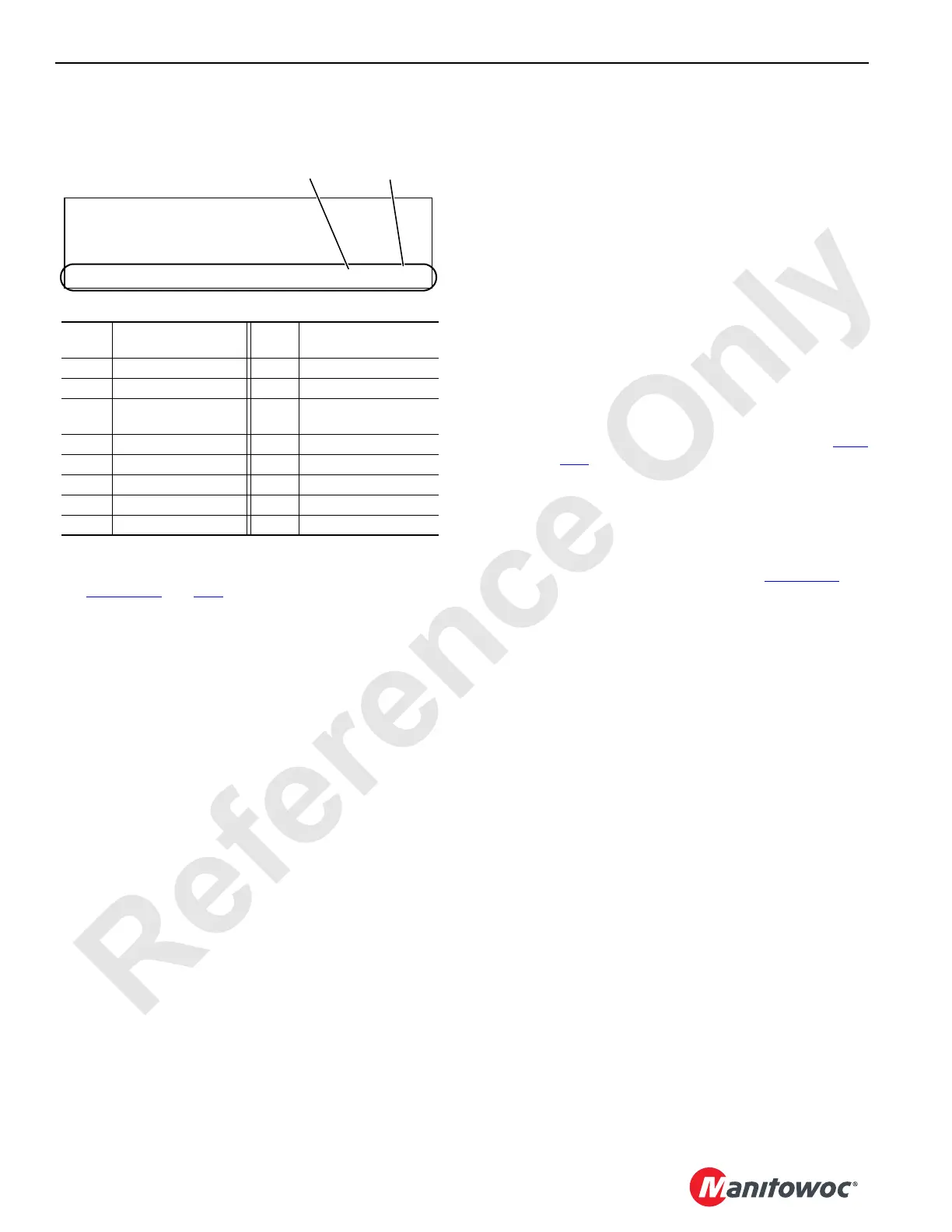

FIGURE 2-27

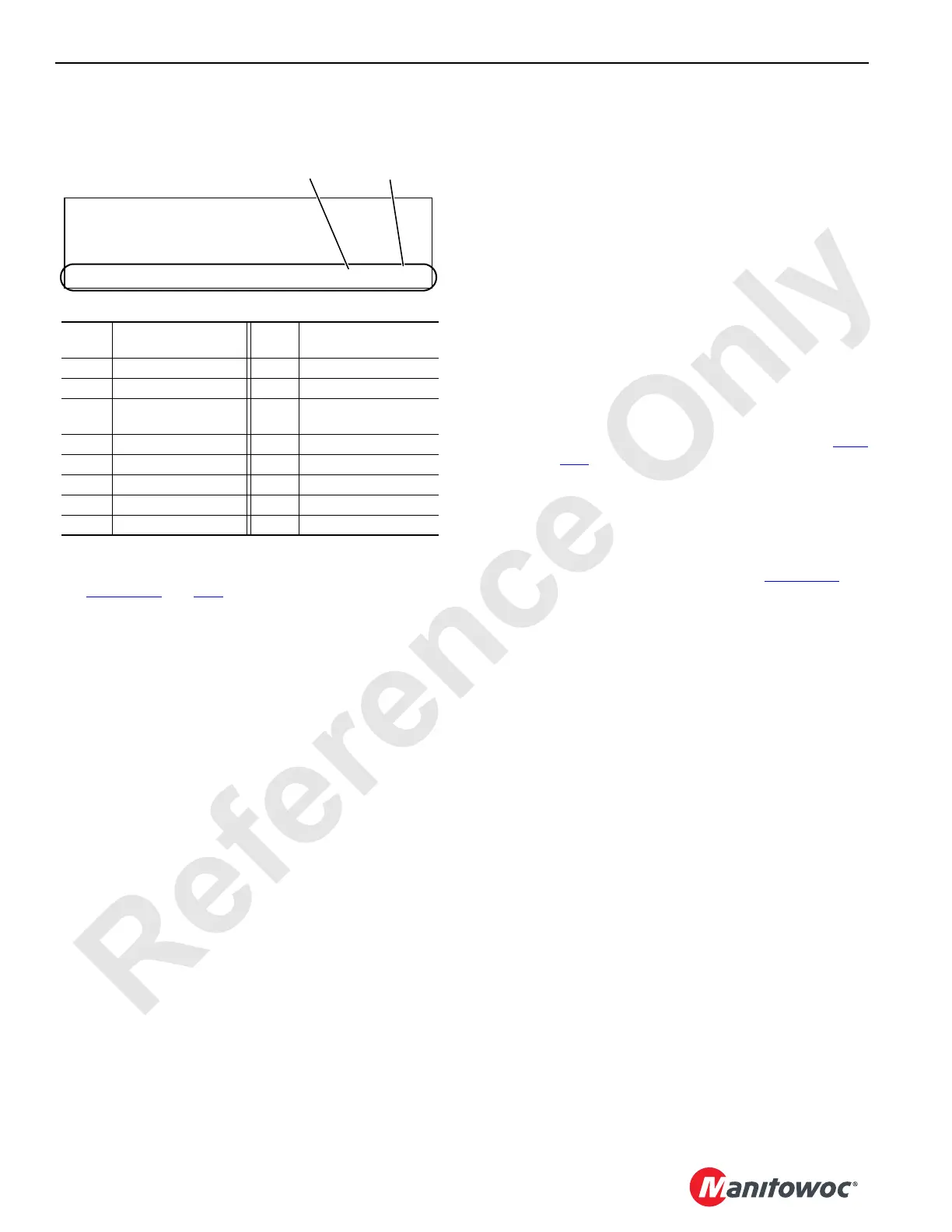

Binary

No.

Pressure Sender

(Bank 1)

Binary

No.

Pressure Sender

(Bank 2)

1 Drum 1/3 (Main Hoist) 1 Swing Left

2 Not Used 2 Swing Right

4 Drum 2/5 (Main Hoist) 4

High Pressure

Accessory Accumulator

8 Accessory System

16 Drum 4 (Boom Hoist)

32 Drum 6 (Luffing Hoist)

64 Left Track

128 Right Track

PRESSURE SENDER CAL

CONTROL CAL

PUMP PRESSURE TEST

CHARGE PRESSURE 32 0

Binary

Number 1

Binary

Number 2

Loading...

Loading...