UNDER CARRIAGE 18000 SERIVCE/MAINTENANCE MANUAL

8-4

Published 12-05-17, Control # 035-23

Adjustment Procedure

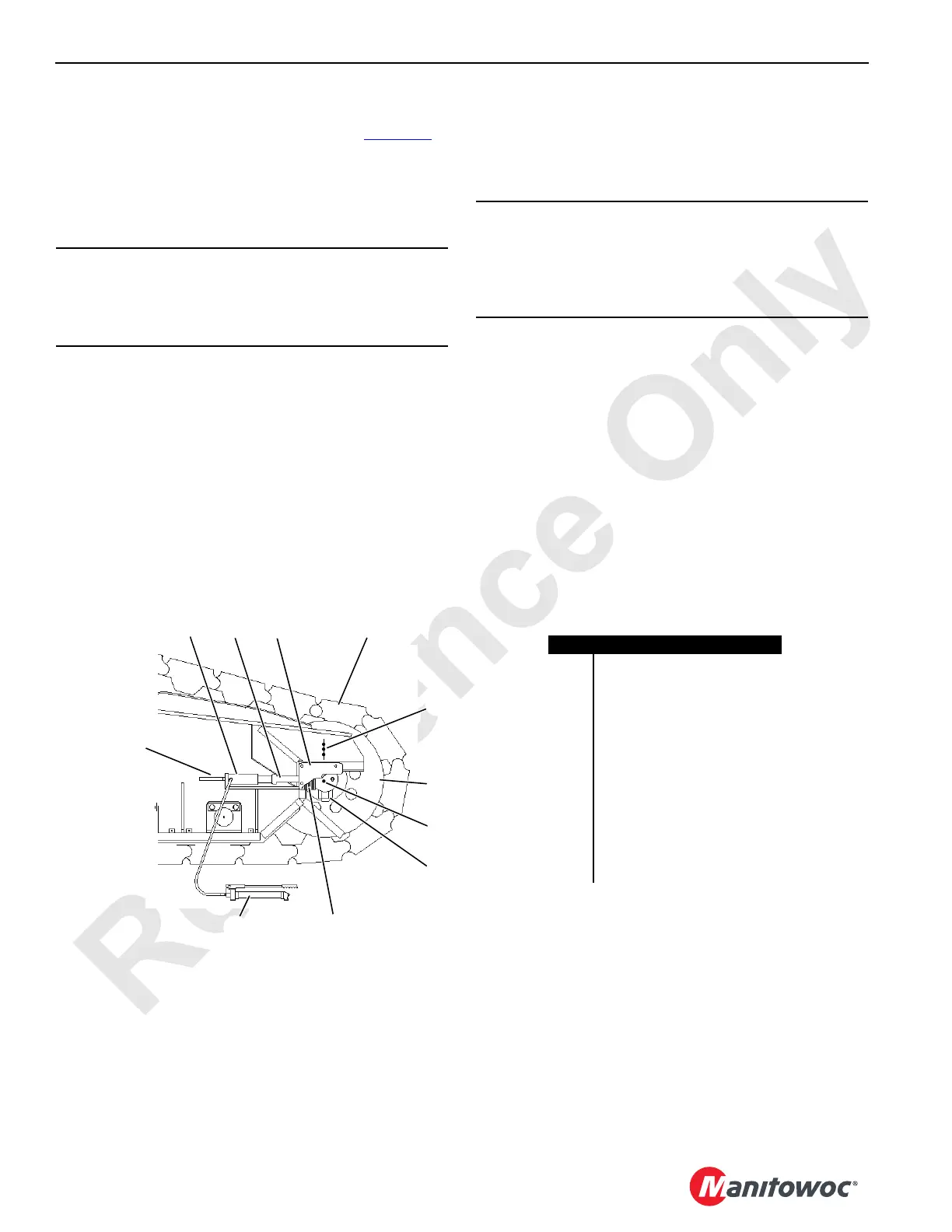

Adjust tread slack at roller end of each crawler (Figure 8-3).

1. Thoroughly clean crawler to be adjusted.

2. Loosen bolt on each side of crawler roller.

3. Remove cover from both sides of crawler frame.

4. Place jacking cylinders on supports on both sides of

crawler frame.

5. Jack against rod an equal amount on both sides of

crawler frame.

6. Add or remove an equal thickness of shims on both

sides of crawler frame.

7. Remove jacking cylinders.

8. Travel crane forward or reverse to tighten shims.

9. Check that dimension from center punch (A) in shaft to

center punch line (B) in crawler frame is same on both

sides of crawler to within 1/8 in (3 mm).

10. Check for proper adjustment (see Adjustment Guideline)

and readjust as required (steps 4 through 9).

11. Tighten nuts on bolts at crawler roller to 2,000 ft-lb

(2 710 Nm) lubricated with Never-Seez or an equivalent

oil and graphite mixture.

12. Install cover on both sides of crawler frame.

NOTE: The extreme limit of tread adjustment occurs when

the bolts are tight against the front end of the slots

in the crawler frame. One crawler tread can be

removed when this limit is reached.

CAUTION

Cylinder Damage!

Two jacking cylinders (one on each side of crawler frame)

are required to prevent damage to single jacking cylinder.

CAUTION

Part Wear!

Crawler roller and tumbler must be square with crawler

frame within 1/8 in (3 mm). Otherwise, parts will wear

rapidly.

FIGURE 8-3

Item Description

1 Hand Pump

2 Support

3 Jacking Cylinder

4Rod

5 Cover

6 Tread

7 Center Punch Line B

8 Crawler Roller

9 Center Punch A

10 Bolts

11 Shims

0.134 in (3 mm) and

0.250 in (6 mm) Thick

7

6

4

5

3

2

1

11

10

8

9

18CSM8-102

Loading...

Loading...