McHale HS2000 Round Bale Wrapper

80

14.4 Table operation

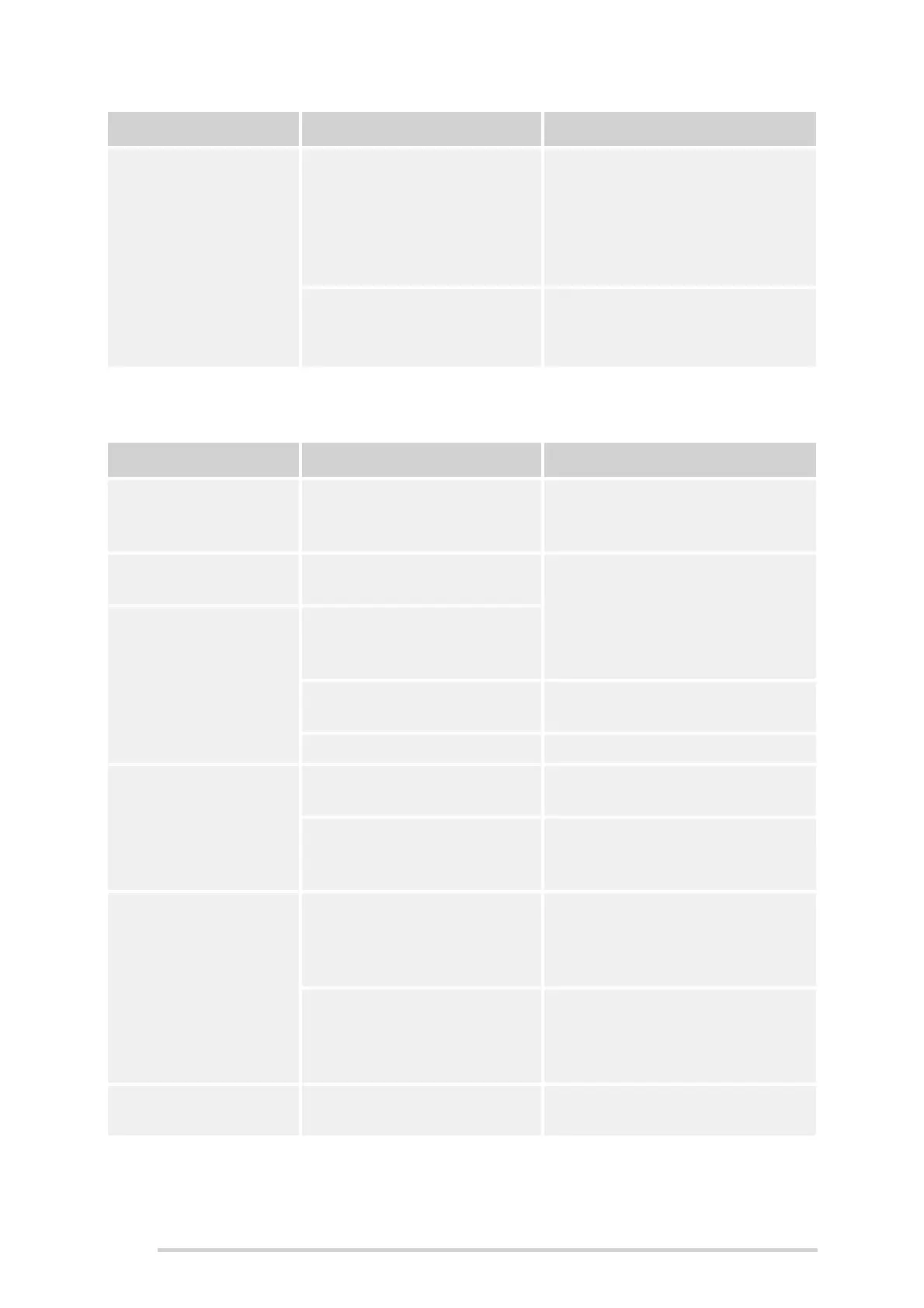

No bounce on main

lift arm

High pressure on return line Ensure that the “tank return”

line is connected “to tank” and

check quick release coupling.

Check tractor manual for

hydraulic connections on trac-

tor

Too high of an oil flow to the

machine

Set oil flow to 35l/min and

ensure oil pressure is at a

minimum of 170 bar

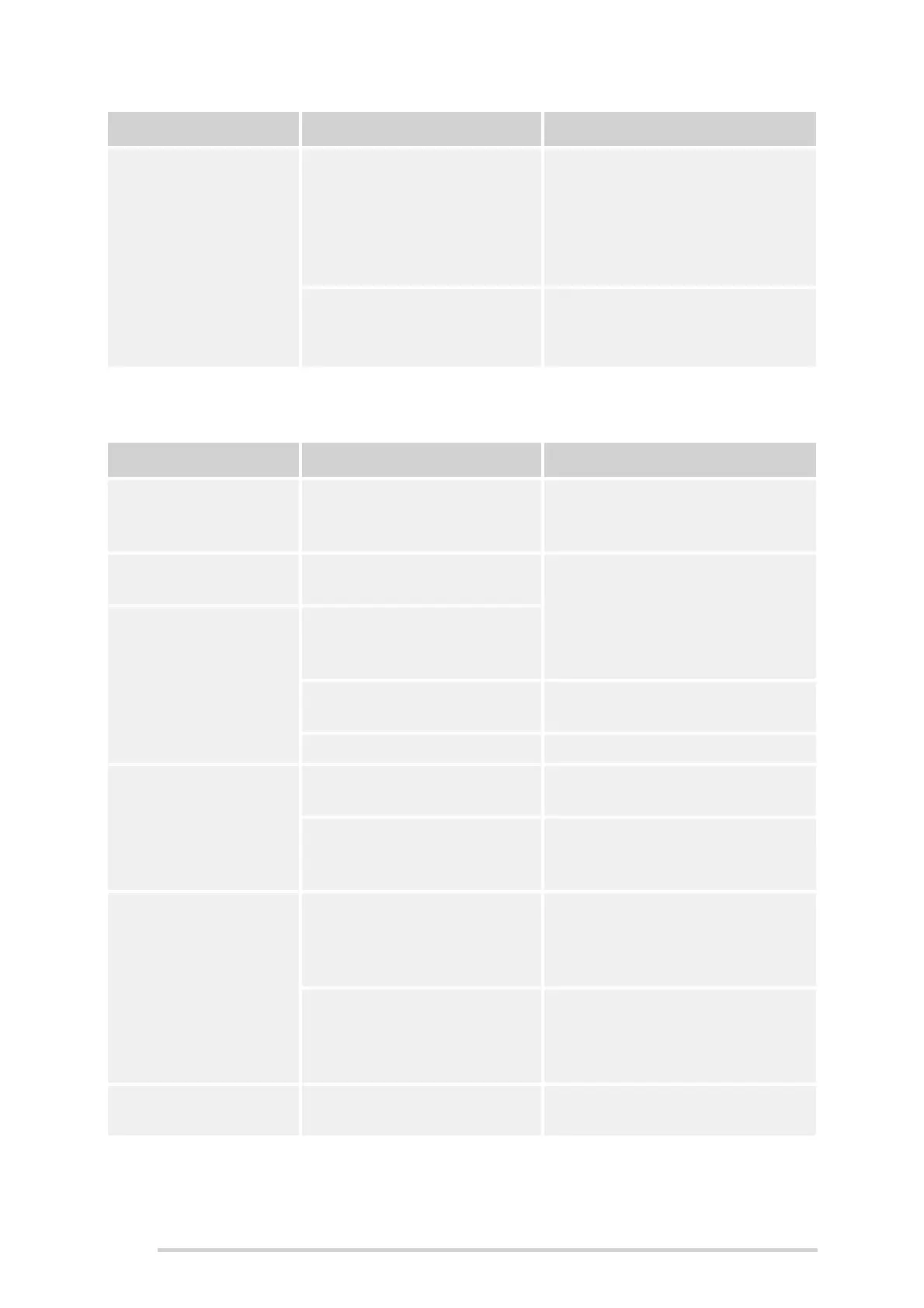

Symptom Reason Solution

Table does not come

forward enough to

accept bale

There is an obstacle block-

ing the table from returning,

e.g. grass

Clear the blockage

Table does not level

properly

The table magnet is not

positioned properly

Please refer to section 10.4, for

magnet positioning

Table tips bale off

machine before

wrapping starts

The table/ dispenser mag-

net is missing or has been

damaged.

Table levelling sensor is

damaged

Replace sensor

Sensor connection is loose Check all sensor connections

Table rollers do not

rotate when dispens-

ers do

The proximity sensor cable

is disconnected

Check electrical connection

The proximity sensor is

damaged or has incorrect

clearance with encoder

See section 10.8, for set-up and

replacement procedure

Table fails to tip auto-

matically

Electrical power supply

fault, e.g. loose connec-

tions, poor battery and/or

charging system

Ensure that a 13V supply is

available and check all electri-

cal connections

Failure to press “Auto tip”

button (“Continuous Cycle”

off) or “Continuous Cycle”

set to off

Ensure that desired cycle is

selected, see section 7.4

Table fails to return

from ‘tip cycle’

The blue magnet(s) has

been damaged/ broken

Replace magnet, see relevant

section 10.4 or 10.5

Symptom Reason Solution

Loading...

Loading...