2 User Manual for the Meca500 Industrial Robot (for rmware 10.1)

INTRODUCTION

1.2. Overall description

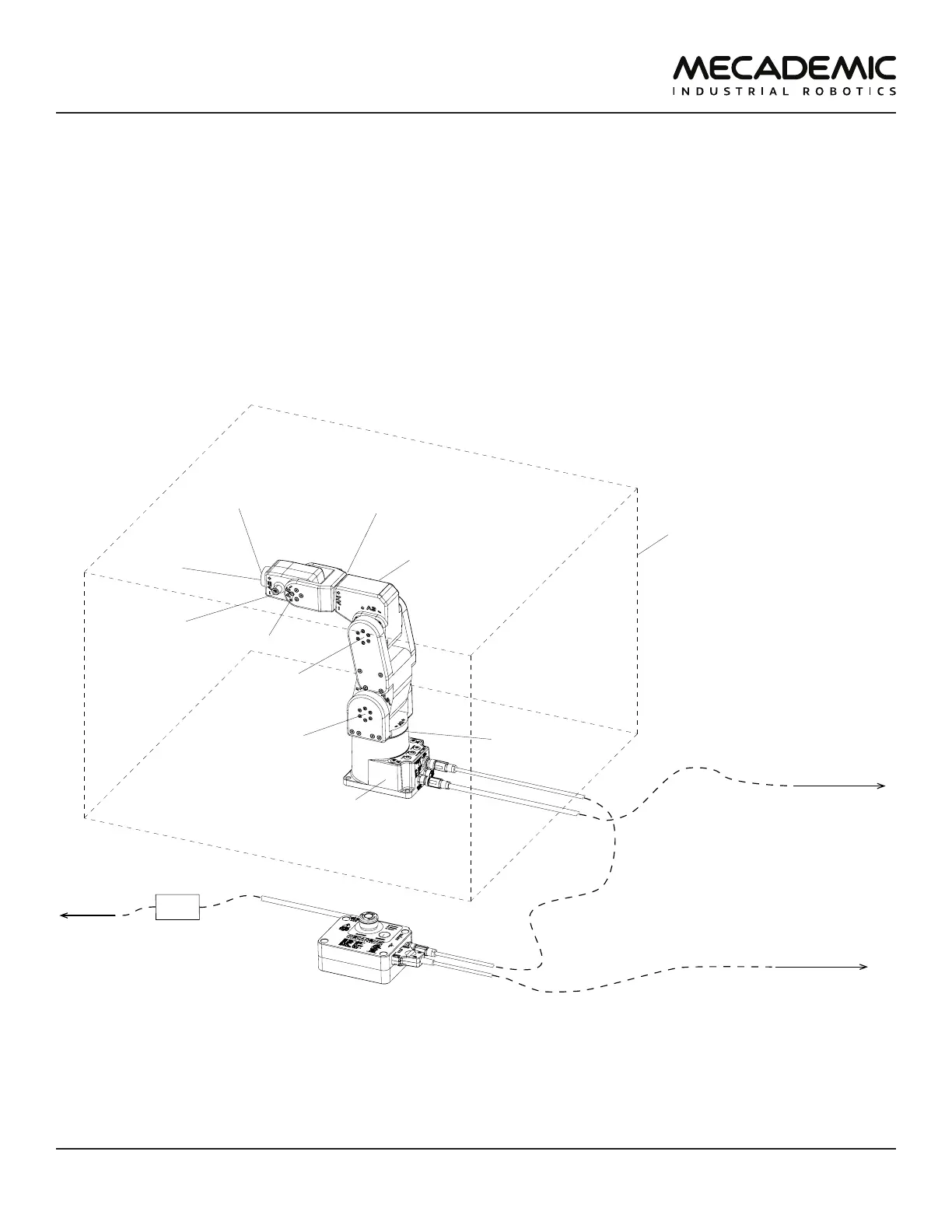

Figure1 shows a schematics of the complete Meca500 robot system in a typical installation. The D-Sub

15-pin dongle provided is not shown as it must be used only during setup and testing. We suggest using

the ASCO Model 241 from Schneider Electric

The Meca500 robot arm consists of seven bodies connected in series through six motorized revolute

joints. The first body is the robot base and the seventh body is the flange (mechanical interface). The

joints are numbered from 1 to 6 , starting from the joint connected to the base, and are labeled on the

robot as A1, A2, ..., A6.

Joints 1, 2 and 3 are equipped with emergency brakes, which are automatically applied when power is

removed from the motors. Joints 4, 5 and 6 have no brakes.

safeguarded enclosure

(not supplied)

power supply

robot arm

surge protector

(not supplied)

DC power cable (2m)

Ethernet cable

with RJ45 jack (2m)

AC power cord

(not supplied)

to computer

or PLC

to standard

electrical

outlet

to safety I/Os

DB15 D-Sub cable

(not supplied)

flange

(for attaching

EOAT)

I/O port for

optional

Mecademic

EOAT

joint 1

(with brake)

joint 2

(with brake)

joint 3

(with brake)

joint 4

joint 5

joint 6

Figure1: Schematics of the Meca500 robot system installed

Loading...

Loading...