8 User Manual for the Meca500 Industrial Robot (for rmware 10.1)

SAFETY

2.3. Robot arm and safety

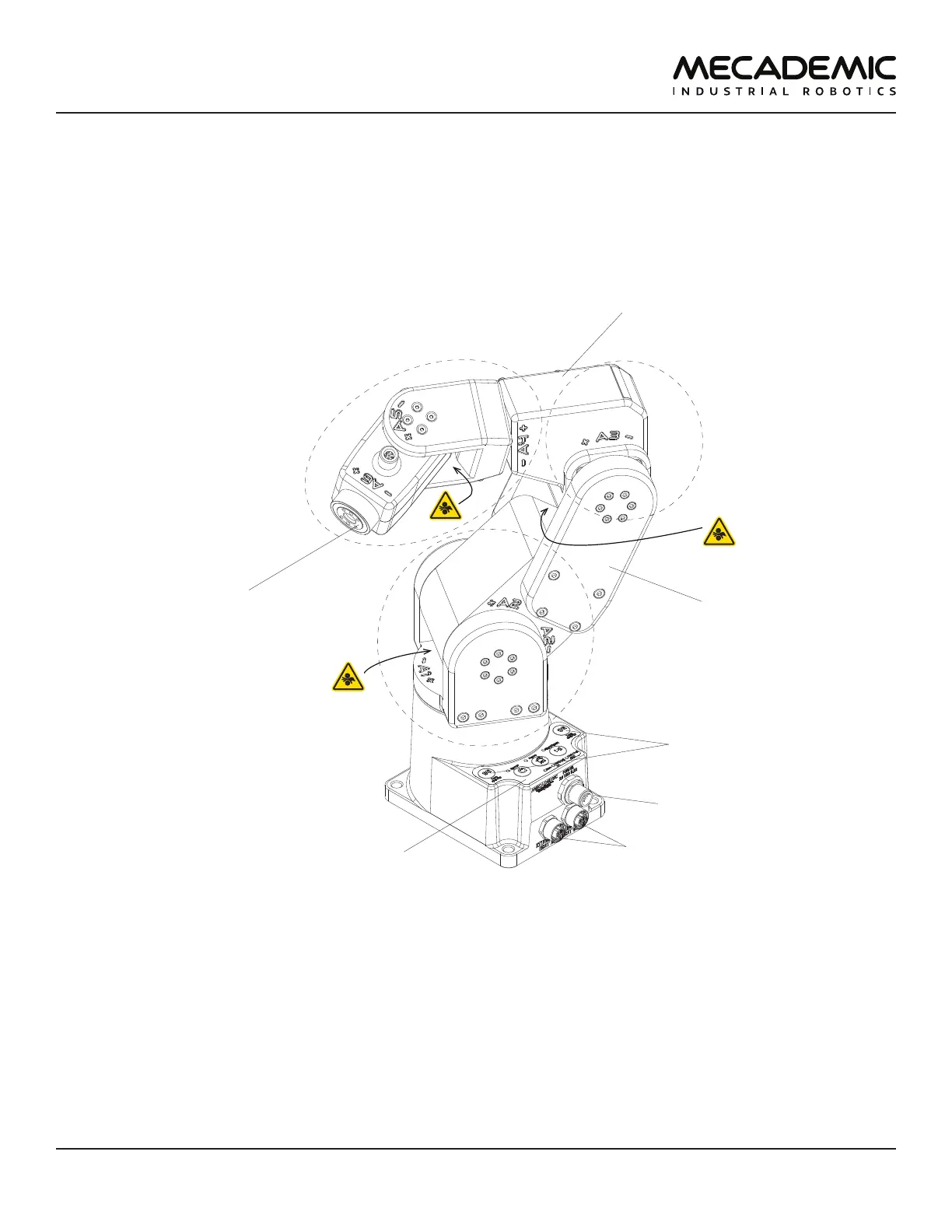

Figure6 shows a description of the main components of the Meca500 robot arm.

DC power connector

flange

(mechanical interface)

0G buttons

control panel

M12 Ethernet connectors

wrist

upper arm

shoulder

elbow

Figure6: Meca500 robot arm

2.3.1 Brakes and limitations

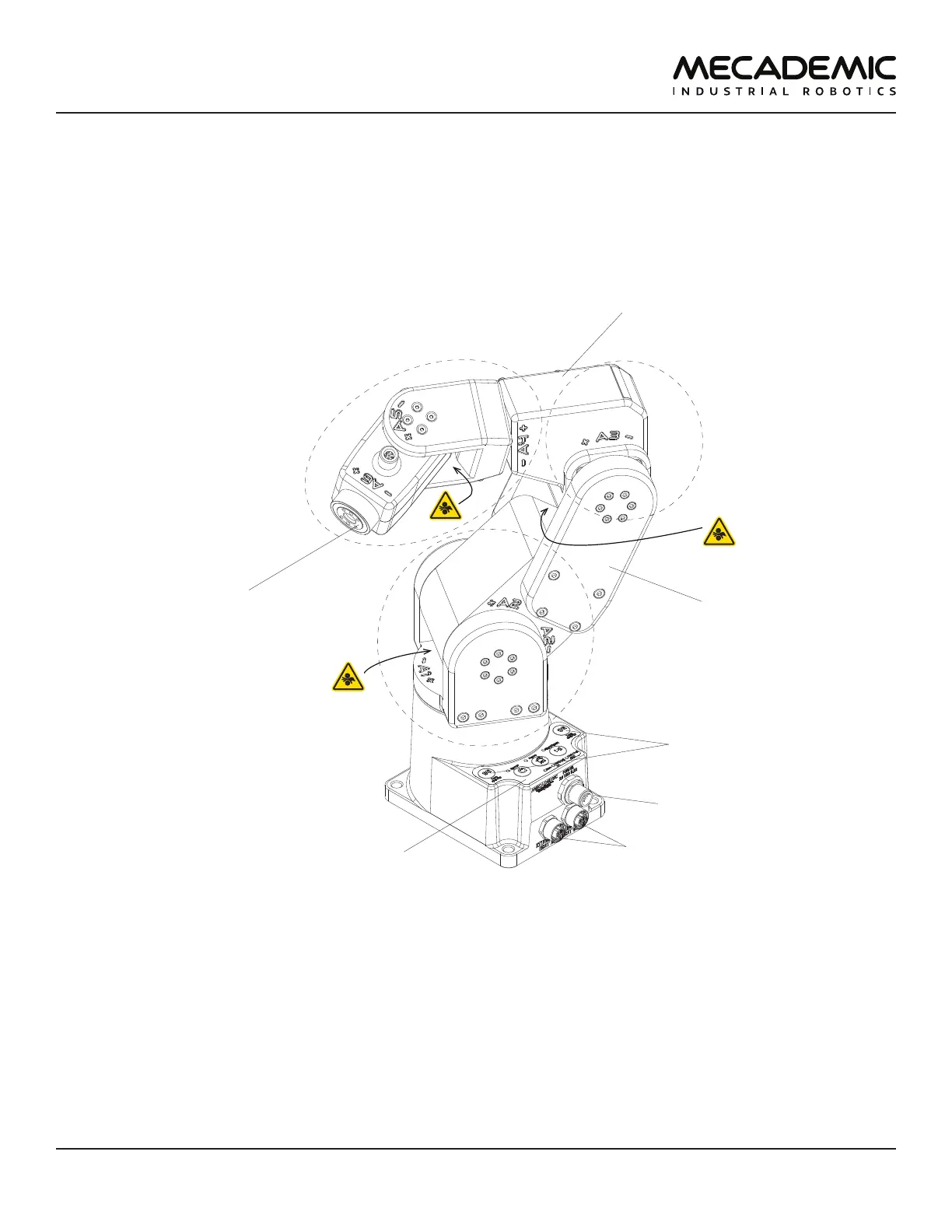

As already mentioned, the Meca500 has brakes on joints 1, 2 and 3 only. Therefore, when the robot is

deactivated, powered off, or put in safety stop (E-Stop or Protective Stop 1), the brakes on joints 1, 2 and

3 will be immediately applied and the joints will be immobilized instantly. Simultaneously, since joints 4,

5 and 6 do not have brakes, they will become free. This minimizes the risks of pinning and pinching from

the wrist and the end-effector. However, beware that the end-effector might slowly move downwards

under the effects of gravity, as shown in Figure7. Depending on the type of end-effector used, this

residual motion might lead to an injury.

Loading...

Loading...