Chapter 3—Installation

15

MOUNTING THE CIRCUIT The circuit monitor is a flush-mounted device that projects through the back

MONITOR of a panel or breaker cell door. Table 3-1 lists typical mounting locations in

various power equipment designs.

Note: Series 2000 circuit monitors use the same cutout dimensions and

hole patterns as the Series 100, 200 circuit monitors, but the required rear clearances

have increased.

When choosing a mounting location, consider the following points:

• Allow for easy access to the rear of the circuit monitor.

• Allow extra space for all wires, shorting blocks, or other components.

• Consider the depth of the circuit monitor. Include extra depth for add–on

modules that you might add in the future. See Appendix A for circuit

monitor dimensions.

• Be sure that ambient conditions fall within the acceptable range: operating

temperature –25°C to +70°C, relative humidity, 5–95% non-condensing.

For CE mounting requirements, see CE Compliance, page 14.

Note: Before preparing the cutout, refer to Appendix A and verify that the

required clearances exist.

To mount the circuit monitor, complete the following steps:

1. Prepare the cutout and mounting holes. Refer to figure 3-2 for exact

dimensions.

2. Insert the circuit monitor through the cutout from the front of the panel

or breaker cell door. Guide the circuit monitor mounting studs through

the holes in the panel.

3. Secure the circuit monitor to the panel using four #10-32 hex nuts

included in the circuit monitor hardware kit (63230-204-16). Figure 3-3

shows the circuit monitor mounted in an electrical panel.

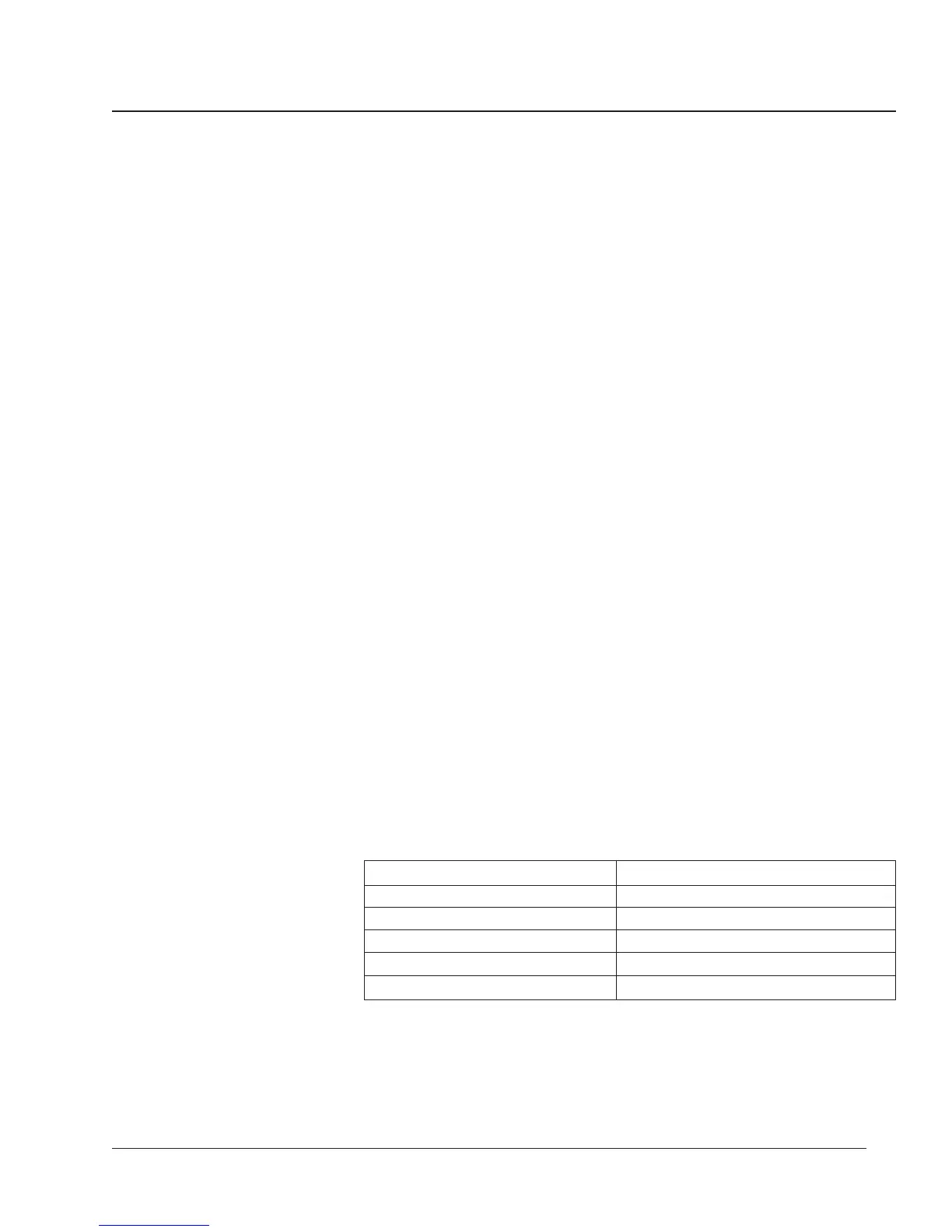

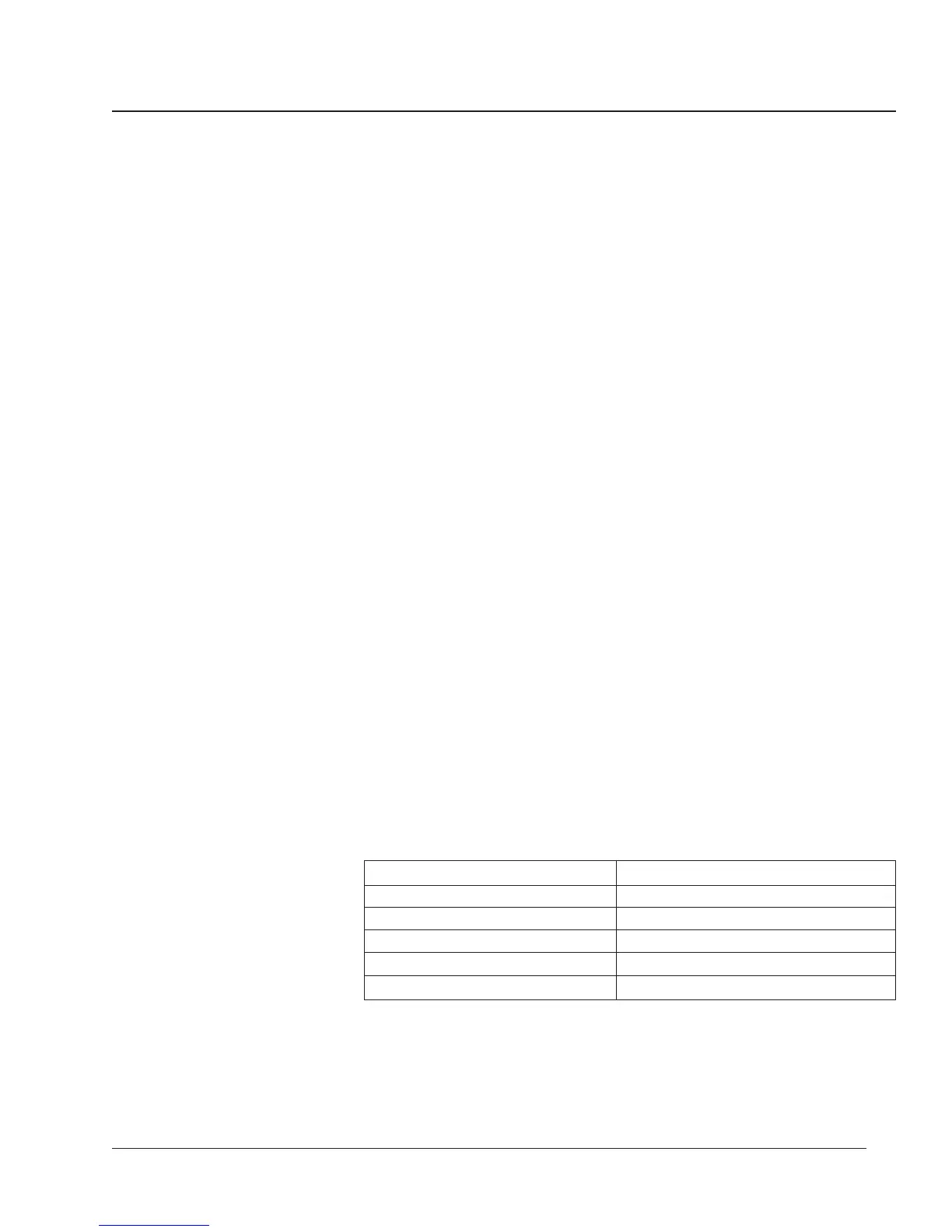

Table 3-1

Typical Circuit Monitor Mounting Locations

Equipment Type Mounting Location

QED Switchboards, Model 6 MCCs Main Meter Location or Aux. Section

POWER-ZONE

III Switchgear Main Instrument Compartment Door

HVL and VISI/VAC

Switchgear 9-inch Front Panel or Instrument Door

Metal-Clad and Substation CBs Standard Relaying Locations

ISO-FLEX

Medium Voltage MCCs Standard Relaying Locations

Loading...

Loading...