4.10 Suppressor

■■■■■■■■■■■■■■■■■■■■■■

80

■■■■■■■■

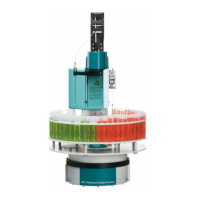

883 Basic IC plus

4.10.3.3 Cleaning the suppressor

In the following cases, it may be necessary to clean the suppressor:

■ Increased backpressure at the suppressor's connection tubing.

■ Irremediable blockage of the suppressor (solutions can no longer be

pumped through the suppressor).

■ Irremediable jamming of the suppressor (suppressor can no longer be

switched over).

Cleaning the suppressor

1

Disconnecting the suppressor from the IC system

■ Switch off the instrument.

■ Disconnect all capillaries of the suppressor from the IC system.

2

Dismantling the suppressor

■ Unscrew the union nut (25-1) from the housing (25-5).

■ Pull the connecting piece (25-2) out of the suppressor drive

together with the rotor (25-3).

If rotor A gets stuck in the suppressor drive, you can push it out as

follows:

Put a pointed object into the slot in the suppressor drive and use

it to push out the rotor A.

■ Loosen the connecting piece from the rotor.

■ Remove the rotor from the adapter.

3

Rinsing the capillaries

■ Connect each of the 6 PTFE capillaries connected to the connect-

ing piece (25-2) in sequential order to the high-pressure pump

and pump ultrapure water through them.

■ Check whether water comes out at the connecting piece.

If one of the capillaries remains blocked, the connecting piece (25-2)

must be replaced (order number 6.2835.010).

4

Cleaning the rotor

■ Clean the sealing surface of the rotor (25-3) with ethanol using a

lint-free cloth.

Loading...

Loading...