Page 85

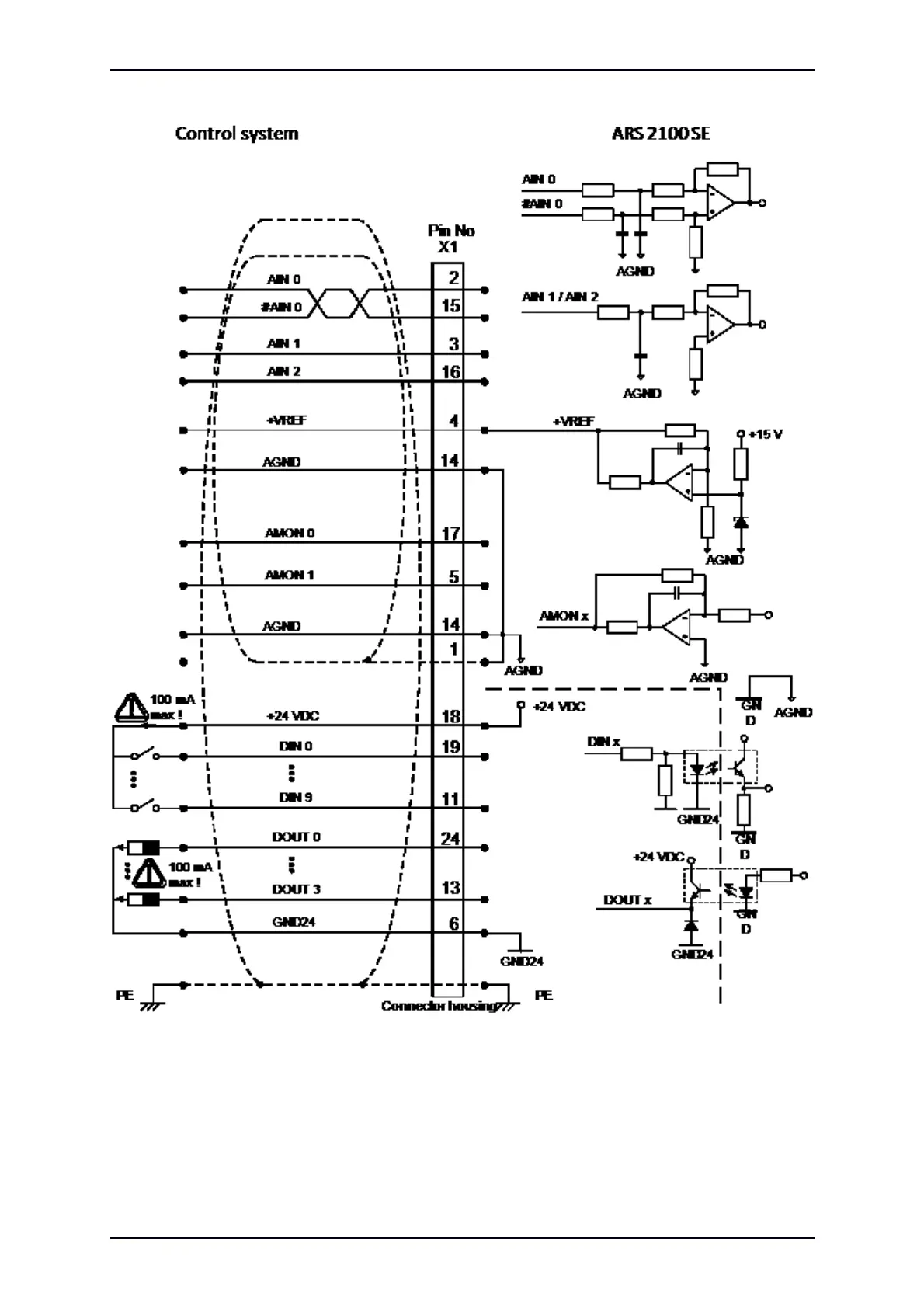

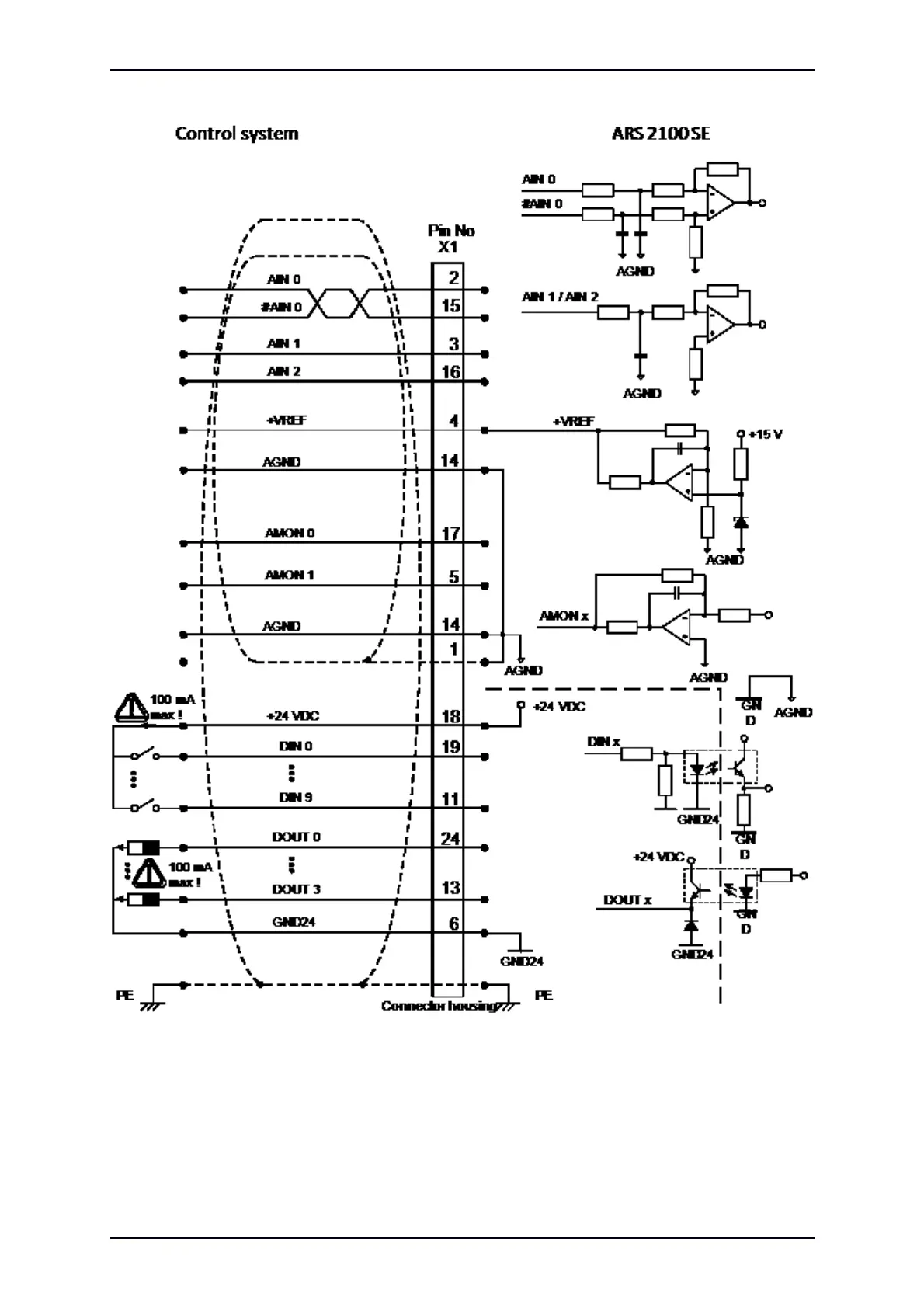

Figure 17: Basic circuit diagram connector [X1]

The servo drive ARS 2100 SE comprises one differential (AIN 0) and two single-ended analogue

inputs, designed for input voltages within a range of 10V. The inputs AIN 0 and #AIN 0 are lead to the

control via twisted cables (twisted pair design).

Product Manual „Servo drives ARS 2100 SE“ Version 5.0

Loading...

Loading...