Page 93

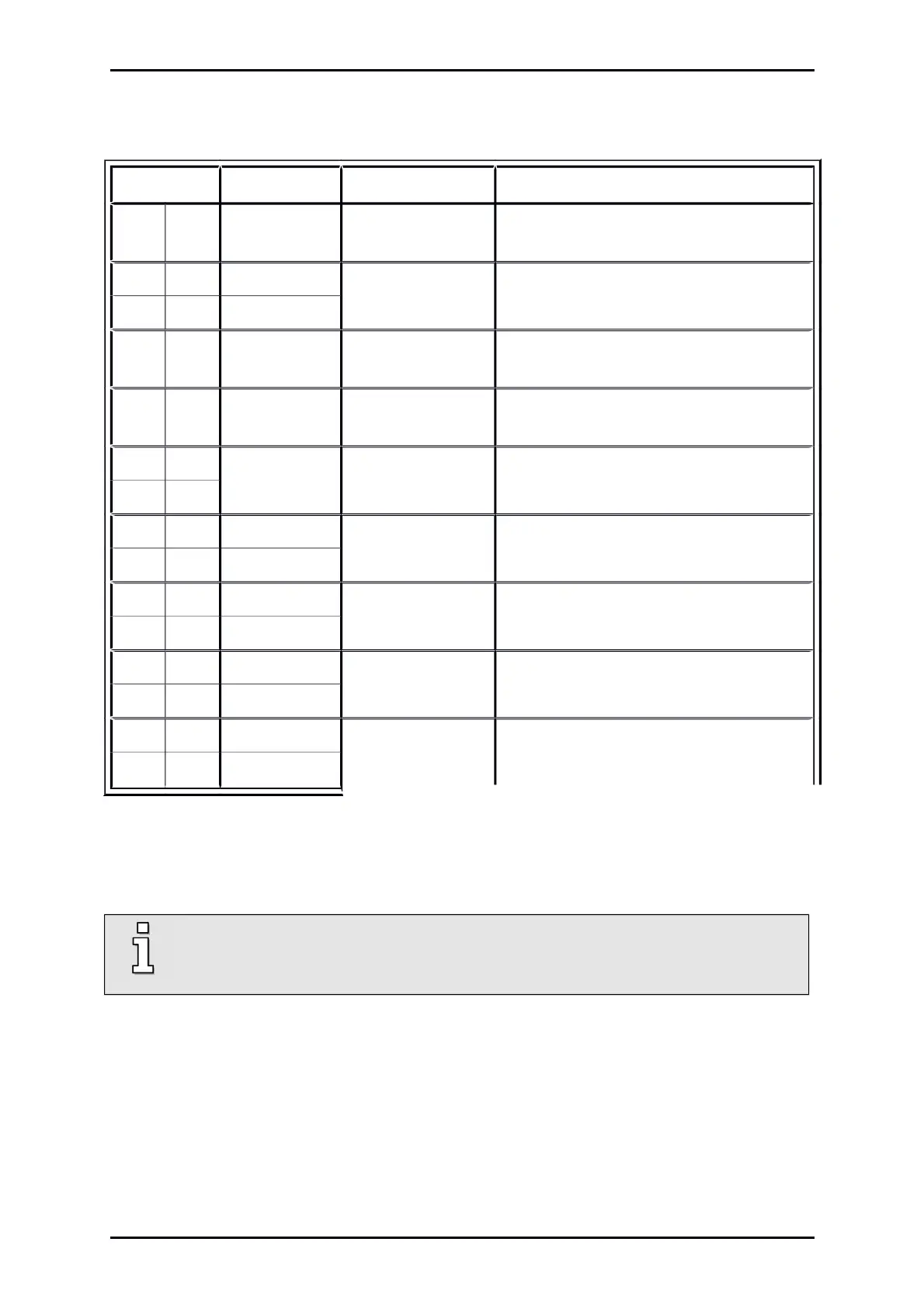

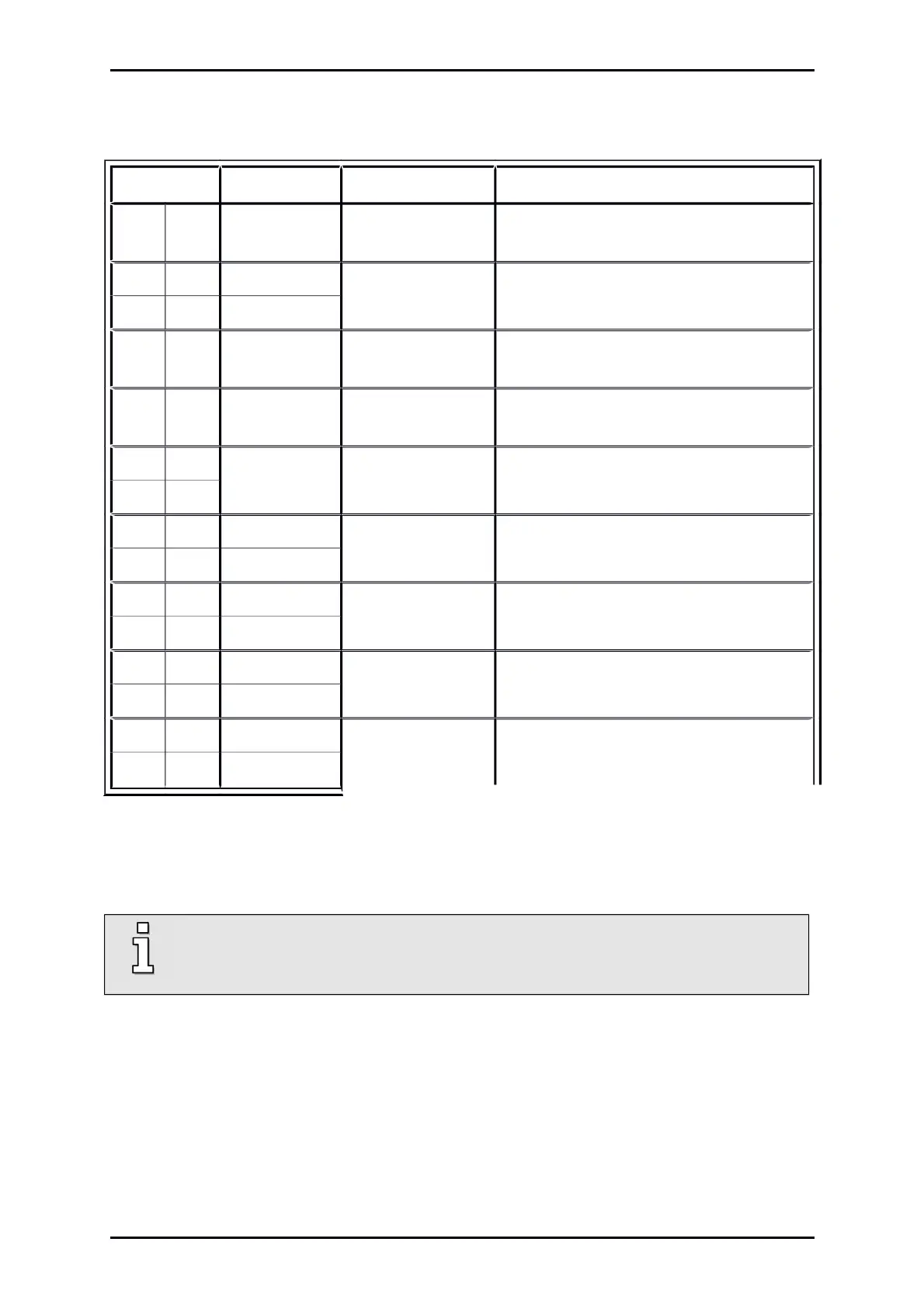

Table 36: Pin assignment: Incremental encoder with serial interface (for example EnDat,

HIPERFACE

®

) [X2B]

Pin No Denomination Values Specification

1 MT+

+3,3V / Ri = 2 k

Motor temperature sensor

1)

, normally closed

contact, PTC, KTY

9 U_SENS+ 5 V ... 12 V

R

I

1 k

Sensor cables for encoder supply

2 U_SENS-

10 US

5 V / 12 V / 10 %

I

max

= 300 mA

Supply voltages for high-resolution

incremental encoder

3 GND 0 V Reference potential encoder supply and

motor temperature sensor

11

4

12 DATA 5 V

SS

R

I

120

Bidirectional RS485 data line (differential)

(EnDat/HIPERFACE

®

)

5 #DATA

13 SCLK 5 V

SS

R

I

120

Clock output RS485 (differential)

(EnDat)

6 #SCLK

14 COS_Z0

2)

1 V

SS

/ 10 %

R

I

120

COSINE trace signal (differential) from high-

resolution incremental encoder

7 #COS_Z0

2)

15 SIN_Z0

2)

1 V

SS

/ 10 %

R

I

120

SINE trace signal (differential) from high-

resolution incremental encoder

8 #SIN_Z0

2)

1)

Please comply with Chapter 9 Additional requirements for the servo drives concerning the UL approval on

page 113.

2)

Heidenhain encoder: ASIN_Z0; BCOS_Z0

In addition, a low-impedance connection of the outer cable shield to the housing of the

servo drive has to be established. Therefore, the outer cable shield of the angle

encoder cable must be connected to the housing of the angle encoder connector.

Product Manual „Servo drives ARS 2100 SE“ Version 5.0

Loading...

Loading...