OM-281426 Page 69

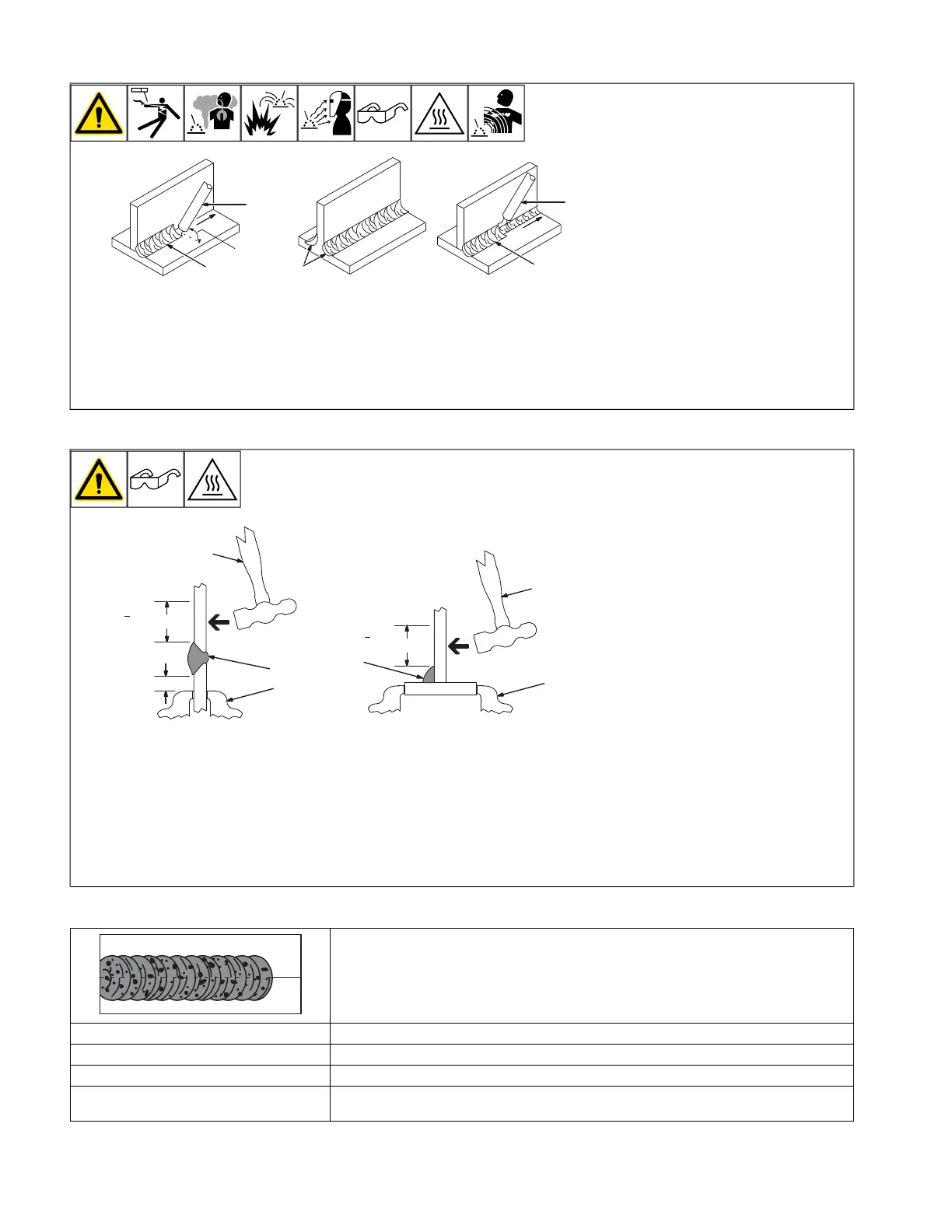

13-11. Welding T-Joints

1-1. Welding Lap Joints

≤ 30

°

≤ 30

°

1

1

2

3

1-2. Welding Groove (Butt) Joints

30

°

2

1

1/16 in.

(1.6 mm)

3

4

1-3. Welding T-Joints

≤ 45

°

1

2

1

3

2

1-4. Weld Test

2 3 in.

1/4 in.

3

2

1

2 3 in.

3

2

1

(51-76 mm)

(6.4 mm)

(51-76 mm)

1 Electrode

2 Fillet Weld

Keep arc short and move at definite rate of

speed. Hold electrode as shown to provide

fusion into the corner. Square edge of the

weld surface.

For maximum strength weld both sides of up-

right section.

3 Multi-Layer Deposits

Weld a second layer when a heavier fillet is

needed. Use any of the weaving patterns

shown in Section 13-8. Remove slag before

making another weld pass.

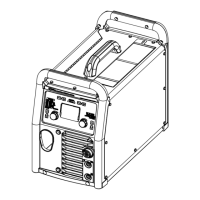

13-12. Weld Test

1-1. Welding Lap Joints

≤ 30

°

≤ 30

°

1

1

2

3

1-2. Welding Groove (Butt) Joints

30

°

2

1

1/16 in.

(1.6 mm)

3

4

1-3. Welding T-Joints

≤ 45°

1

2

1

3

2

1-4. Weld Test

2 3 in.

1/4 in.

3

2

1

2 3 in.

3

2

1

(51-76 mm)

(6.4 mm)

(51-76 mm)

1 Vise

2 Weld Joint

3 Hammer

Strike the weld joint in the direction shown. A

good weld bends over but does not break.

If the weld breaks, examine it to determine

the cause.

If the weld is porous (many holes), the arc

length was probably too long.

If the weld contains bits of slag, the arc may

have been too long or the electrode was

moved incorrectly which allowed molten slag

to be trapped in the weld. This may happen

on a V-groove joint made in several layers

and calls for additional cleaning between

layers.

If the original beveled surface is visible the

material was not fully melted which is often

caused by insufficient heat or too fast a trav-

el speed.

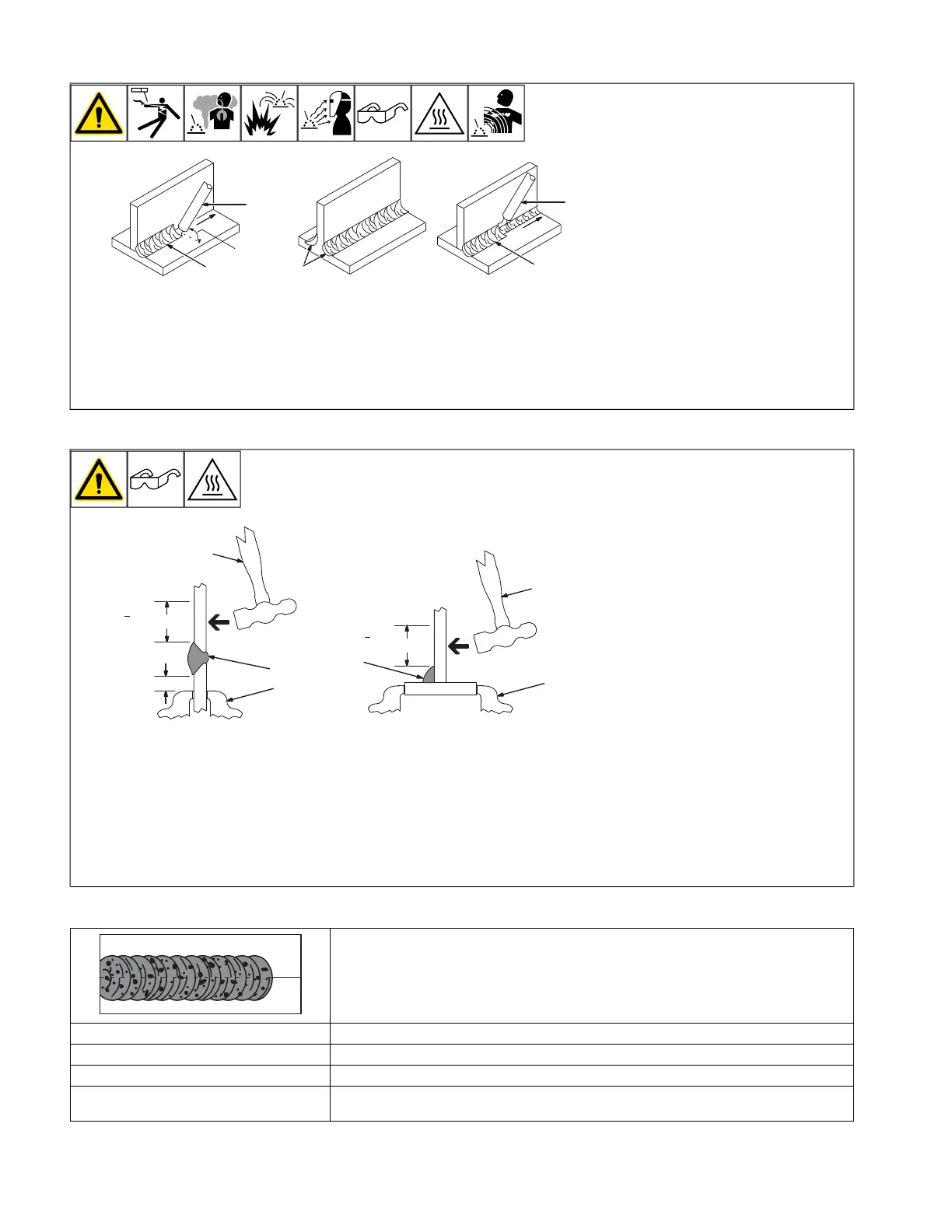

13-13. Troubleshooting

Porosity - small cavities or holes resulting from gas pockets in weld metal.

Possible Causes Corrective Actions

Arc length too long. Reduce arc length.

Damp electrode. Use dry electrode.

Workpiece dirty. Remove all grease, oil, moisture, rust, paint, coatings, slag, and dirt from work surface before

welding.

Loading...

Loading...