4G9 ENGINE (E-W) -

Piston and Connecting Rod

11A-11-6

PWEE9502

E

May 1995Mitsubishi Motors Corporation

"

F

A

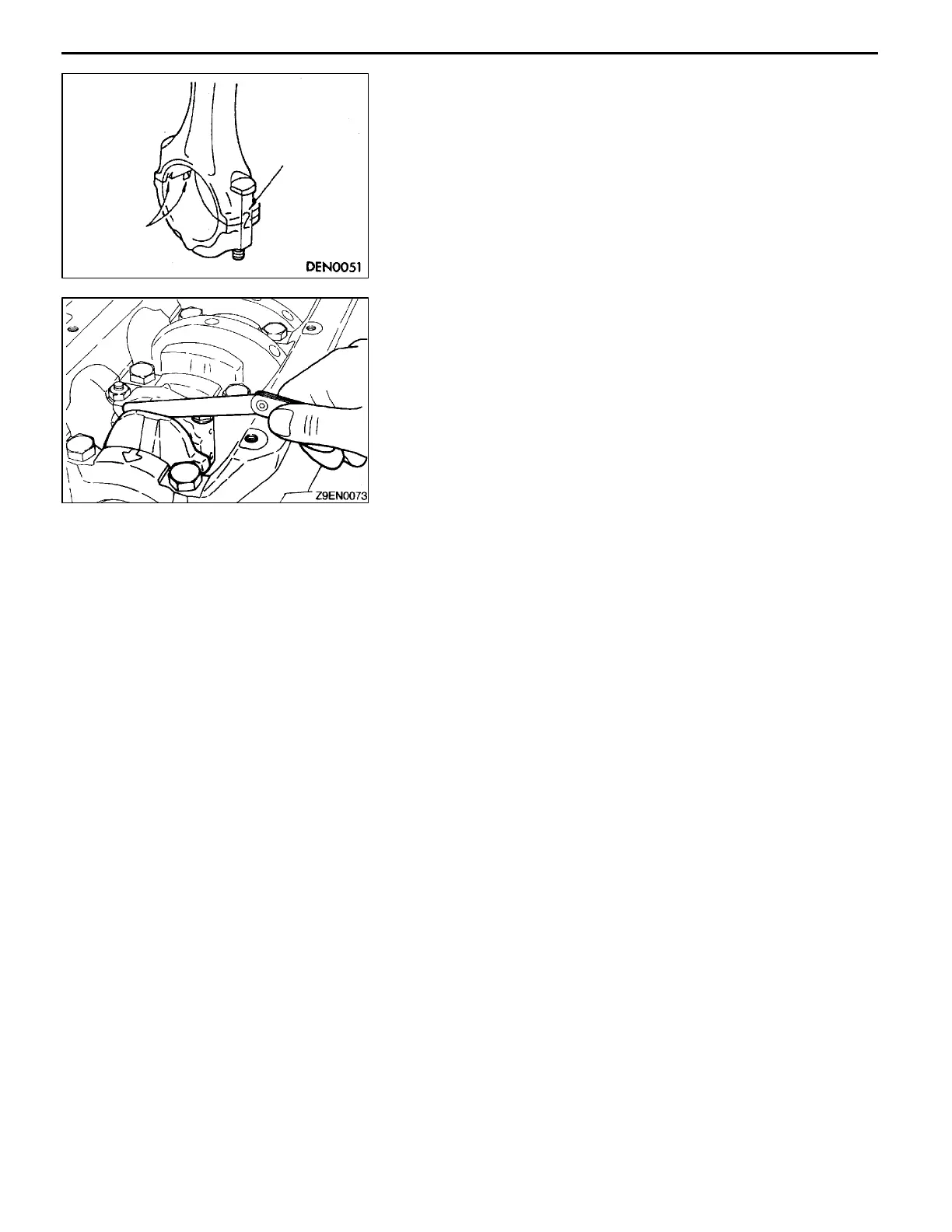

CONNECTING ROD CAP INSTALLATION

(1) Mate the correct bearing cap with the correct connecting

rod by checking with the alignment marks marked during

disassembly. If a new connecting rod has no alignment

mark, position the notches for locking the bearing on

the same side.

(2) Check if the thrust clearance in the connecting rod big

end is correct.

Standard value: 0.10 - 0.25 mm

Limit: 0.4 mm

"

G

A

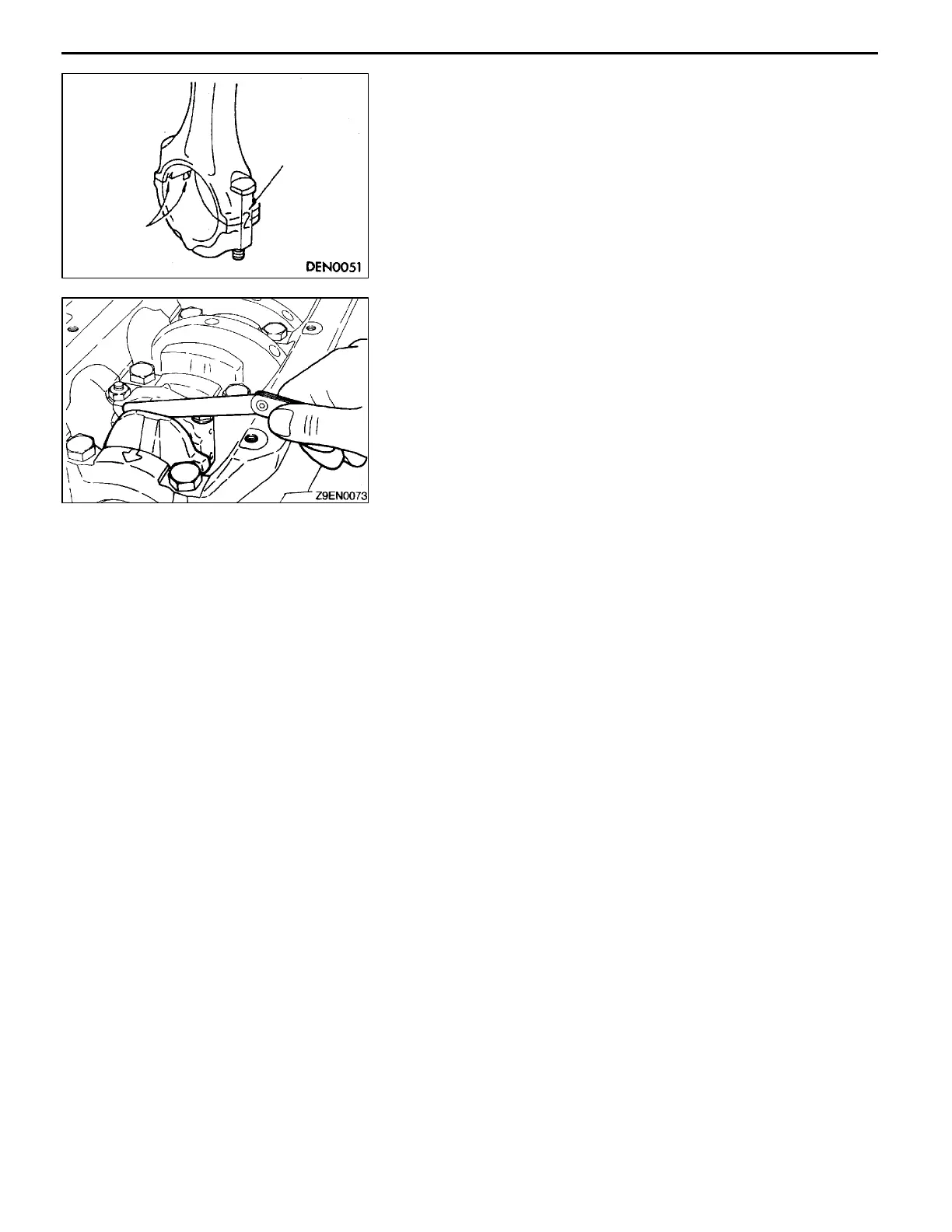

CONNECTING ROD CAP NUT INSTALLATION

Caution

If the cylinder head has been installed before installing

the connecting rod cap nut, be sure to remove the spark

plugs.

(1) Since the connecting rod cap bolts and nuts are torqued

using the plastic area tightening method, the bolts should

be examined BEFORE reuse. If t he bolt threads are

“necked down”, the bolt should be replaced.

Necking can be checked by running a nut with fingers

to the full length of the bolt threads. If the nut does not

run down smoothly, the bolt should be replaced.

(2) Before installation of each nut, apply engine oil to the

thread portion and bearing surface of the nut.

(3) Install each nut to the bolt and tighten it with fingers.

Then tighten the nuts alternately to install the cap properly.

(4) Tighten the nuts to a torque of 20 Nm.

Cylinder No.

Notches

Loading...

Loading...