5.2 Relays

In your PLC programs you will often need to store intermediate binary results (a signal state of

“0” or “1”) temporarily for future reference. The PLC has special memory cells available for this

purpose known as “auxiliary relays”, or “relays” for short (device identifier: "M").

You can store the binary result of an operation in a relay, for example with an OUT instruction,

and then use the result in future operations. Relays help to make programs easier to read and

also reduce the number of program steps: You can store the results of operations that need to

be used more than once in a relay and then poll it is often as you like in the rest of the program.

In addition to normal relays the controllers of the MELSEC System Q also have retentive or

“latched” relays. The normal unlatched relays are all reset to a signal state of “0” when the PLC

power supply is switched off, and this is also their standard state when the controller is

switched on. In contrast to this, latched relays retain their current states when the power is

switched off and on again.

*

You can set the number of latched and unlatched relays with the PLC parameters. The values shown above are the

initial settings.

5–4 MITSUBISHI ELECTRIC

Relays Devices in Detail

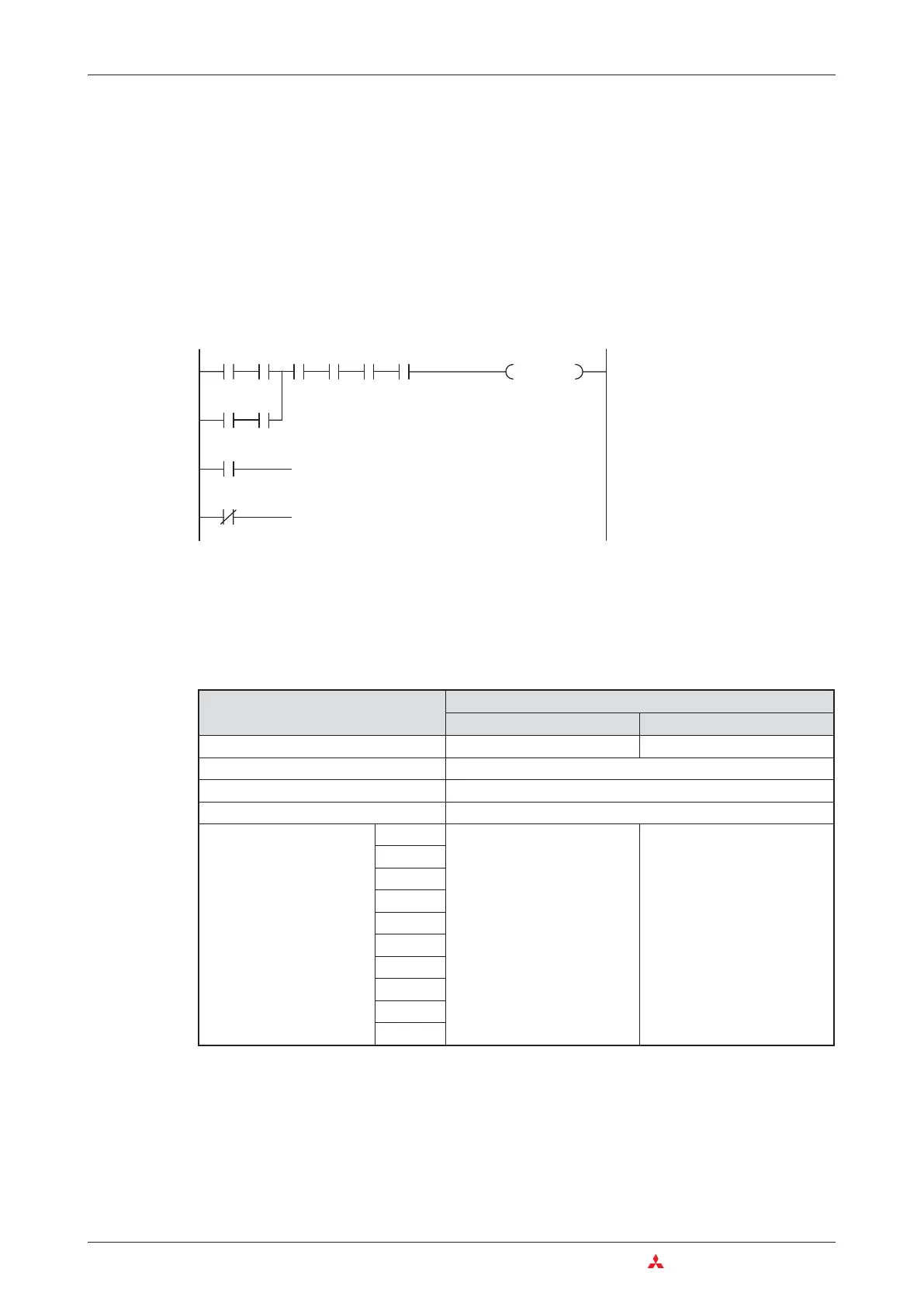

M1

M1

M1

Poll for signal state “1” (relay set)

Poll for signal state “0” (has the relay been reset?)

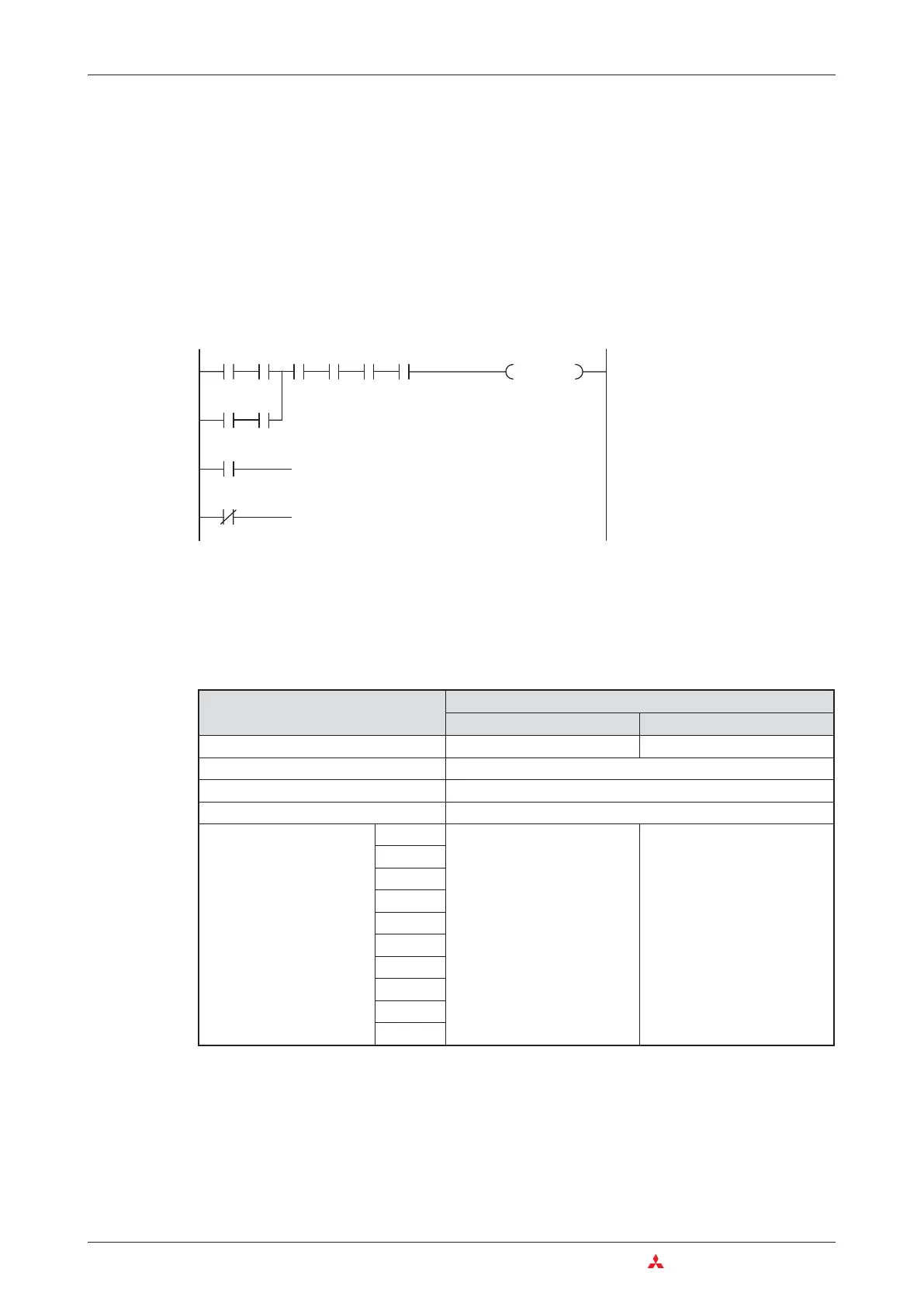

Device

Relay types

Unlatched relays Latched relays

Device identifier M L

Device type Bit device

Possible values for a device 0 or 1

Device address format Decimal

Number of devices and

addresses

Q00J

8192 (M0–M8191)* 8192 (L0–L8191)*

Q00

Q01

Q02

Q02H

Q06H

Q12H

Q25H

Q12PH

Q25PH

Loading...

Loading...