4.9 Programming PLC Applications

Programmable logic controllers provide an almost unlimited number of ways to link inputs with

outputs. Your task is to choose the right instructions from the many supported by the control

-

lers of the MELSEC System Q to program a suitable solution for your application.

This chapter provides a simple example that demonstrate the development of a PLC applica

-

tion from the definition of the task to the finished program.

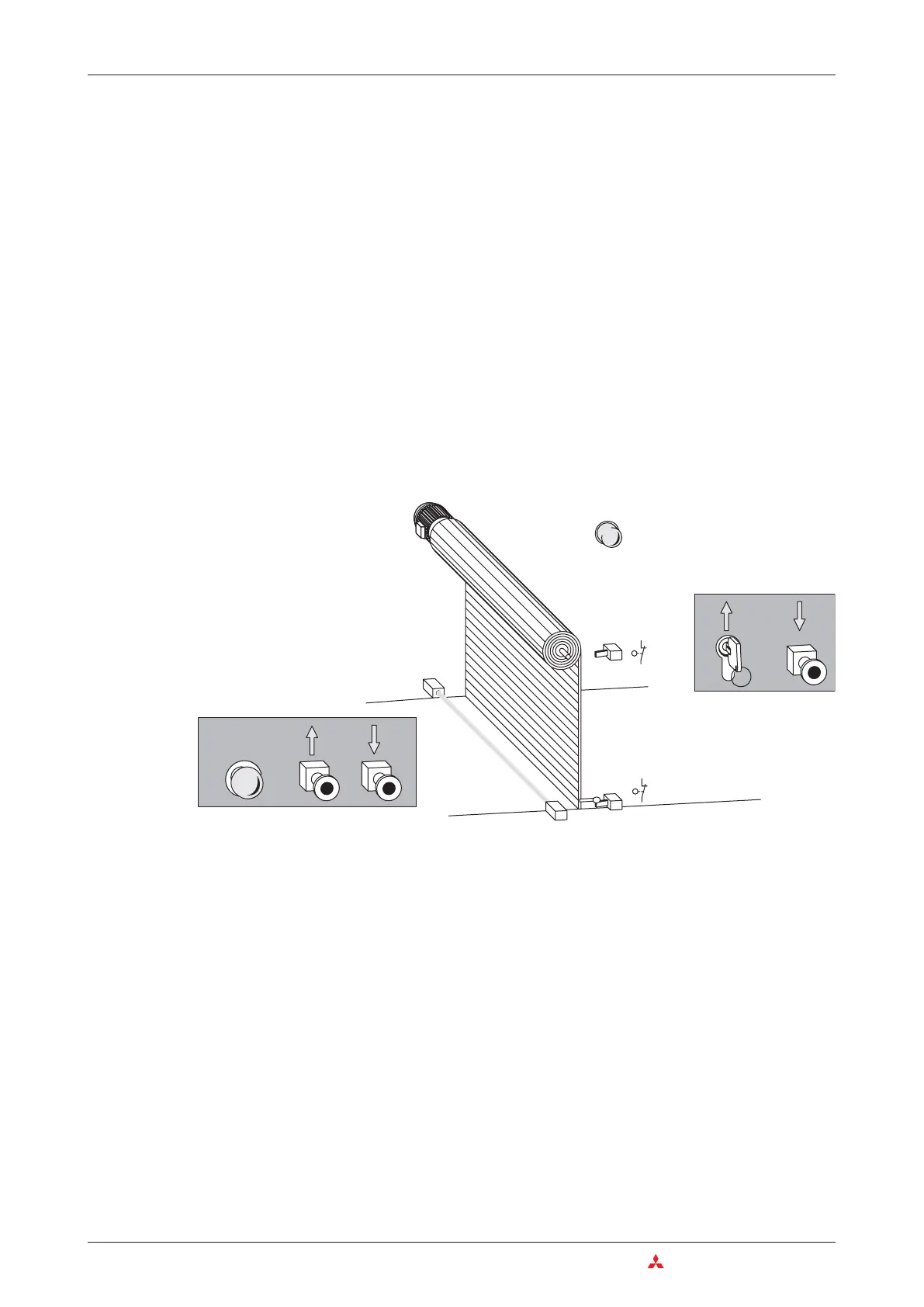

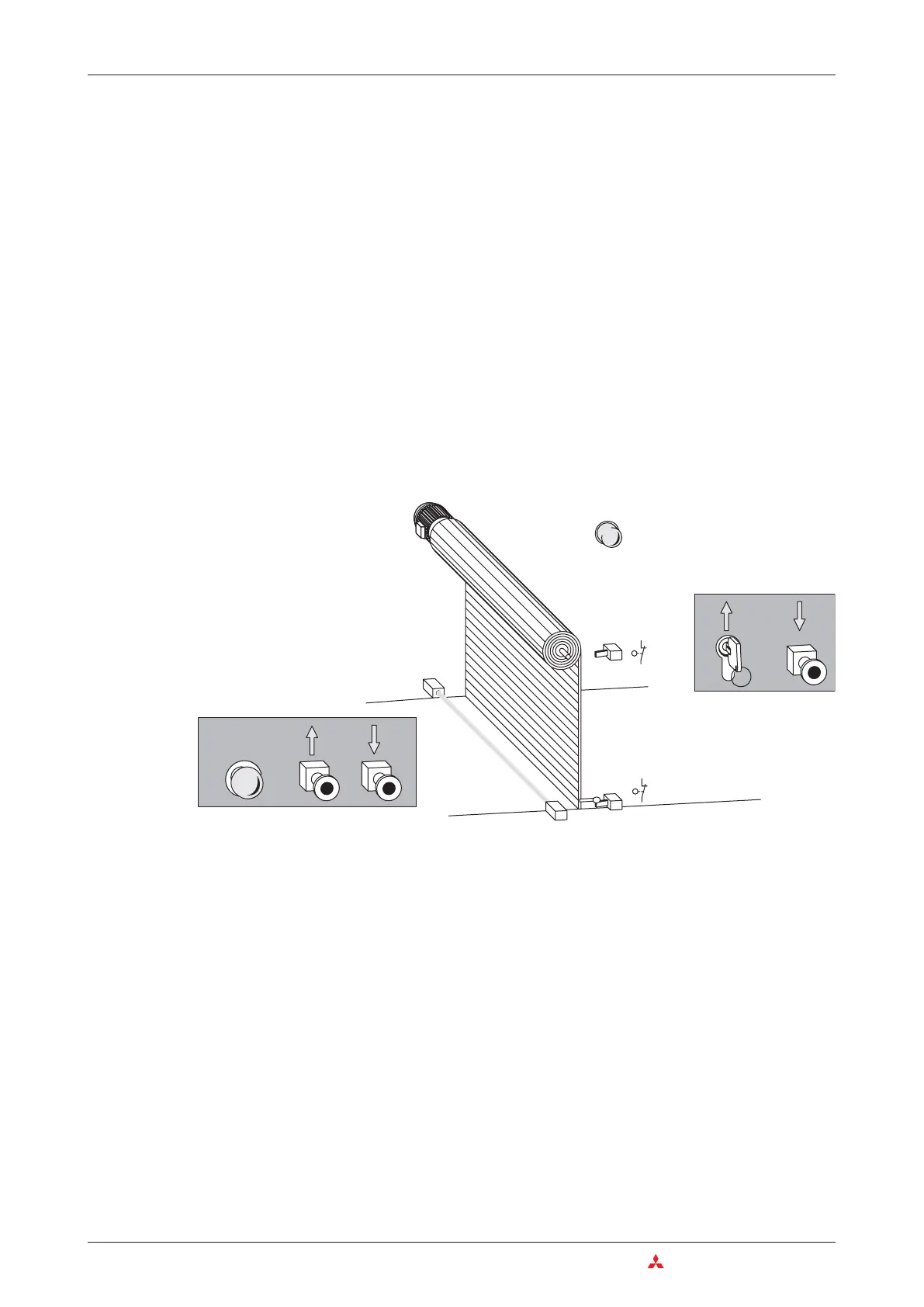

4.9.1 A rolling shutter gate

The first step is to have a clear concept of what you want to do. This means that you need to

take a “bottom-up” approach and write a clear description of what it is you want the PLC to do.

Task description

We want to implement a control system for a warehouse’s rolling shutter gate that will enable

easy operation from both outside and inside. Safety facilities must also be integrated in the

system.

쎲

Operation

–

It must be possible to open the gate from outside with the key-operated switch S1 and to

close it with pushbutton S5. Inside the hall it should be possible to open the gate with

pushbutton S2 and to close it with S4.

–

An additional time switch must close the gate automatically if it is open for longer than

20 s.

–

The states “gate in motion” and “gate in undefined position” must be indicated by a

blinking warning lamp.

쎲

Safety facilities

–

A stop button (S0) must be installed that can halt the motion of the gate immediately at any

time, stopping the gate in its current position. This Stop switch is not an Emergency OFF

function, however! The switch signal is only processed by the PLC and does not switch any

external power connections.

4–34 MITSUBISHI ELECTRIC

Programming PLC Applications An Introduction to Programming

STOP

S1

WarninglampH1

S5

S3

S6

S7

S0 S2 S4

Loading...

Loading...