4.7.3 Using switches and sensors

Before we continue with the description of the rest of the instructions we should first describe

how signals from switches, sensors and so on can be used in your programs.

PLC programs need to be able respond to signals from switches, buttons and sensors to per

-

form the correct functions. It is important to understand that program instructions can only poll

the binary signal state

of the specified input – irrespective of the type of input and how it is

controlled.

Usually, switches with make contacts are used. Sometimes, however, break contacts are used

for safety reasons – for example for switching off drives (see section 4.8).

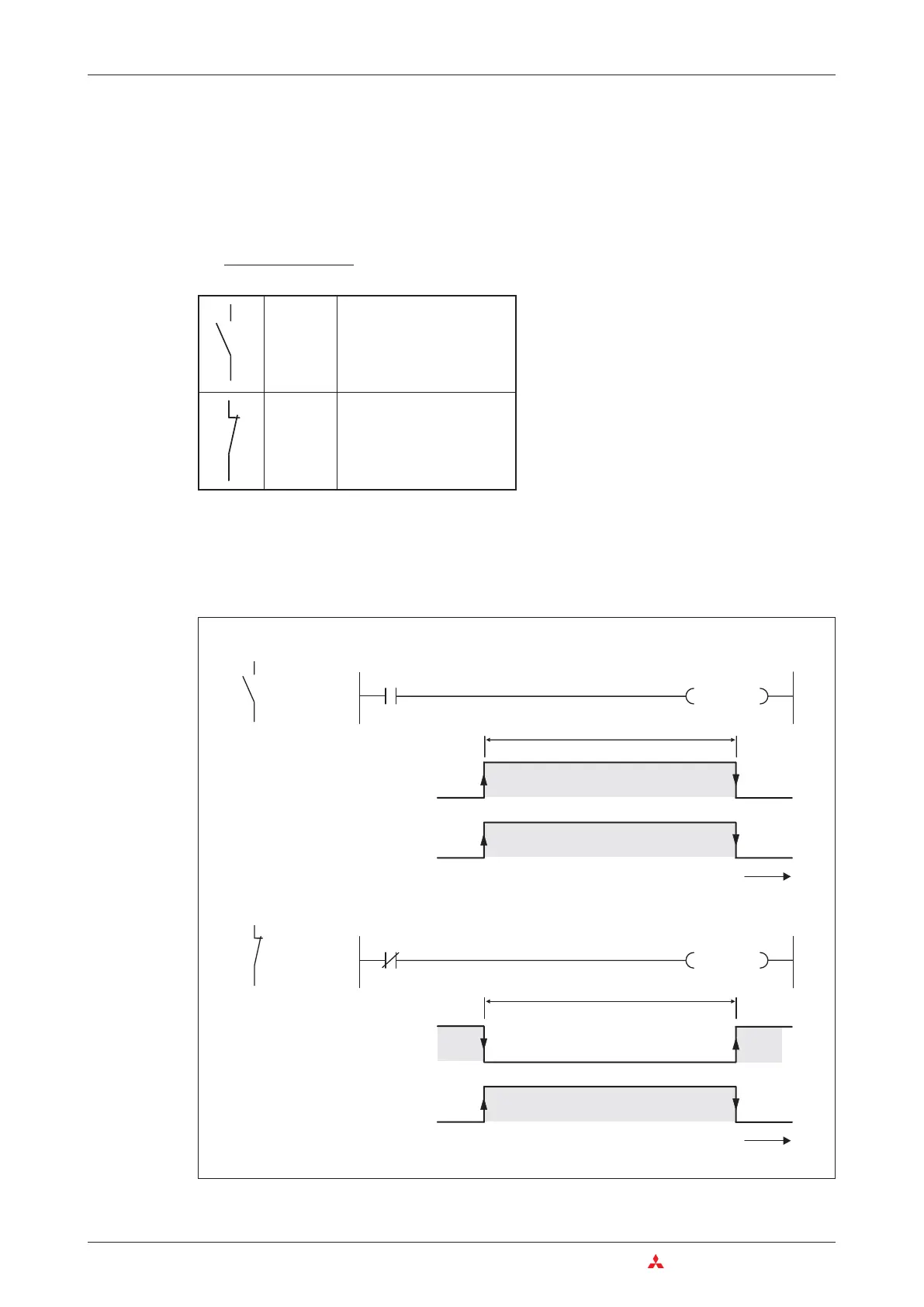

The illustration below shows two program sequences in which the result is exactly the same,

even though different switch types are used: When the switch is operated the output is set

(switched on).

4–16 MITSUBISHI ELECTRIC

The Basic Instruction Set An Introduction to Programming

Normally

open con

-

tact (make

contact)

When a make normally open

contact is operated the input

is set (ON, signal state “1”)

Normally

closed

contact

(break

contact)

When a normally closed con

-

tact is operated the input is

reset (OFF, signal state “0”)

As you can imagine, this means that when

you are writing your program you need to be

aware whether the element connected to the

input of your PLC is a make or a break device.

An input connected to a make device must be

treated differently to an input connected to a

break device. The following example illustra

-

tes this.

Y010

X000

24 V

X0

Y10

X0

OFF

ON

OFF

ON

t

Y010

X000

24 V

X0

Y10

X0

OFF

ON

OFF

ON

t

Switch operated

Switch operated

Loading...

Loading...