4.7.9 Generating pulses

*

PLC and PLF instructions can be used to set outputs (Y) and relays (M).

These instructions effectively convert a static signal into a brief pulse, the duration of which

depends on the length of the program cycle. If you use PLS instead of an OUT instruction the

signal state of the specified device will only be set to “1” for a single program cycle, specifically

during the cycle in which the signal state of the device before the PLS instruction in the circuit

switches from “0” to “1” (rising edge pulse).

The PLF instruction responds to a falling edge pulse and sets the specified device to “1” for a

single program cycle, during the cycle in which the signal state of the device before the PLF

instruction in the circuit switches from “1” to “0” (falling edge pulse).

4–28 MITSUBISHI ELECTRIC

The Basic Instruction Set An Introduction to Programming

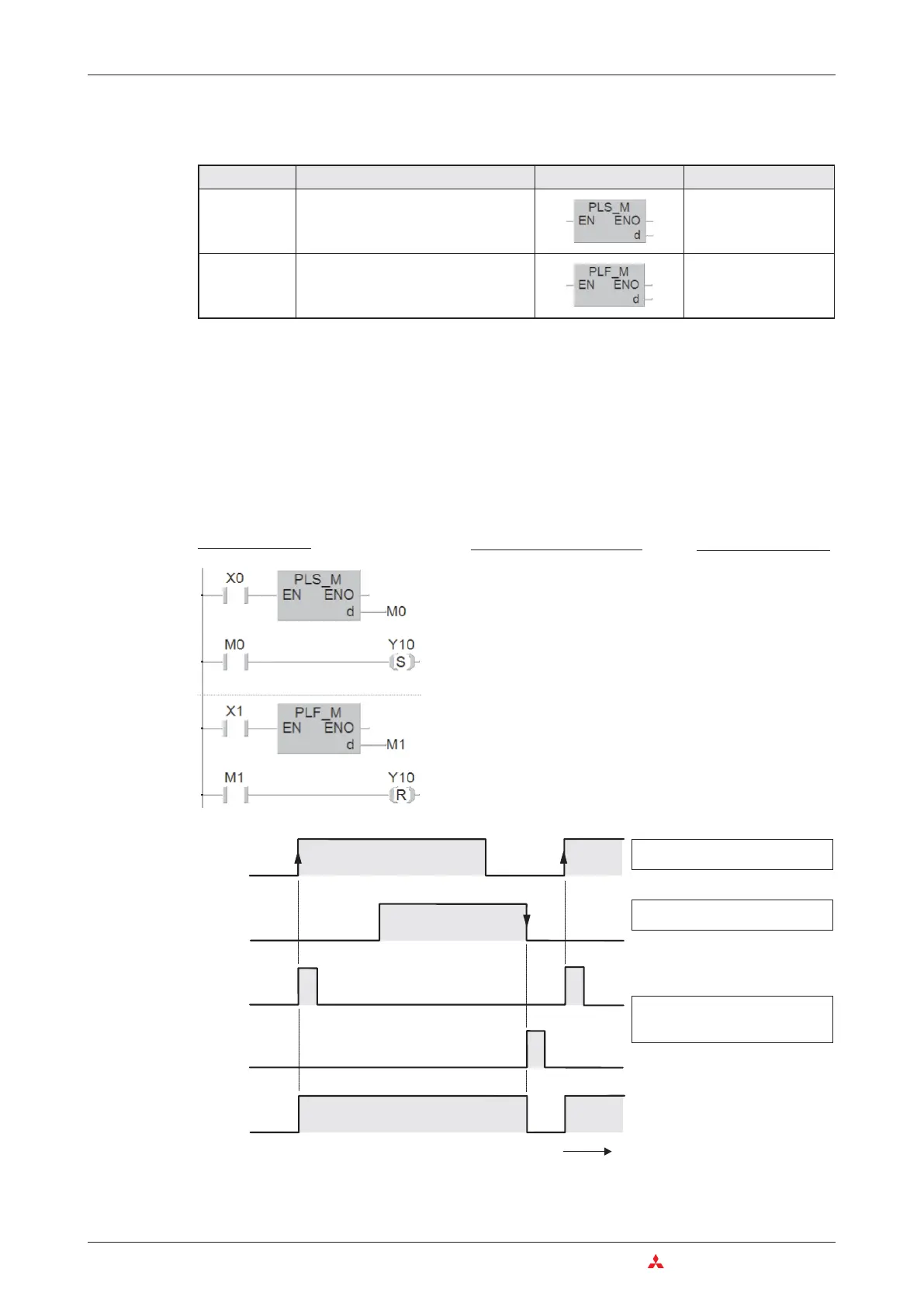

Instruction Function Ladder Diagram IEC Instruction List

PLS

Pulse, sets an device* for the duration of

a single program cycle on the rising edge

of the switching pulse of the input condi

-

tion / device

PLS_M

PLF

Pulse Falling, sets a device* for the dura

-

tion of a single program cycle on the fall

-

ing edge of the switching pulse of the

input condition / device

PLF_M

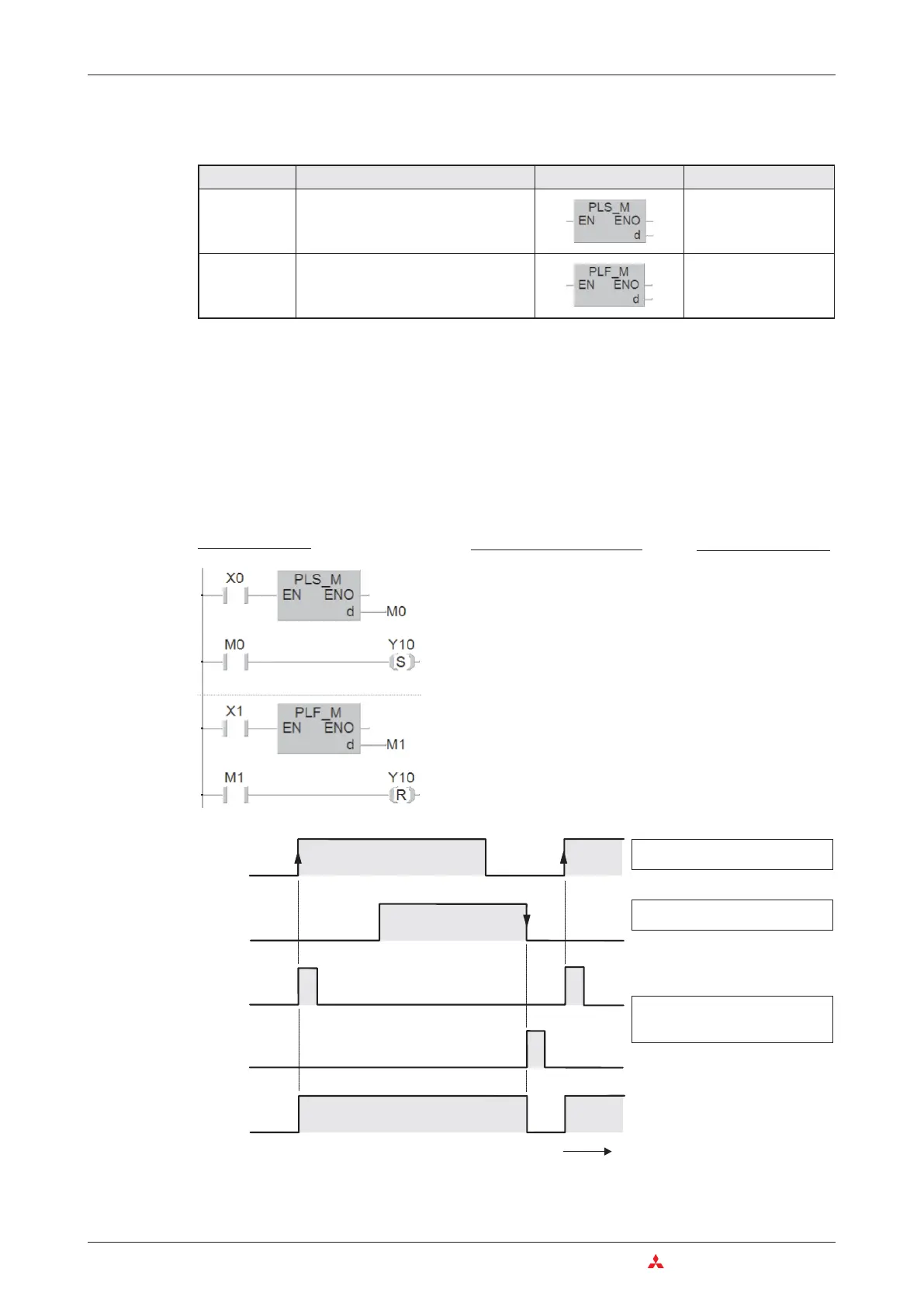

Ladder Diagram

MELSEC Instruction List

LD X0

PLS M0

LD M0

SET Y10

LD X1

PLF M1

LD M1

RST Y10

IEC Instruction List

LD X0

PLS_M M0

LD M0

SY10

LD X1

PLF_M M1

LD M1

RY10

M1

X1

M0

Y10

X0

t

The rising edge of the device X0

signal triggers the function.

Relays M0 and M1 are only

switched on for the duration of a

single program cycle.

In the case of device X1 the falling

edge of the signal is the trigger.

Loading...

Loading...