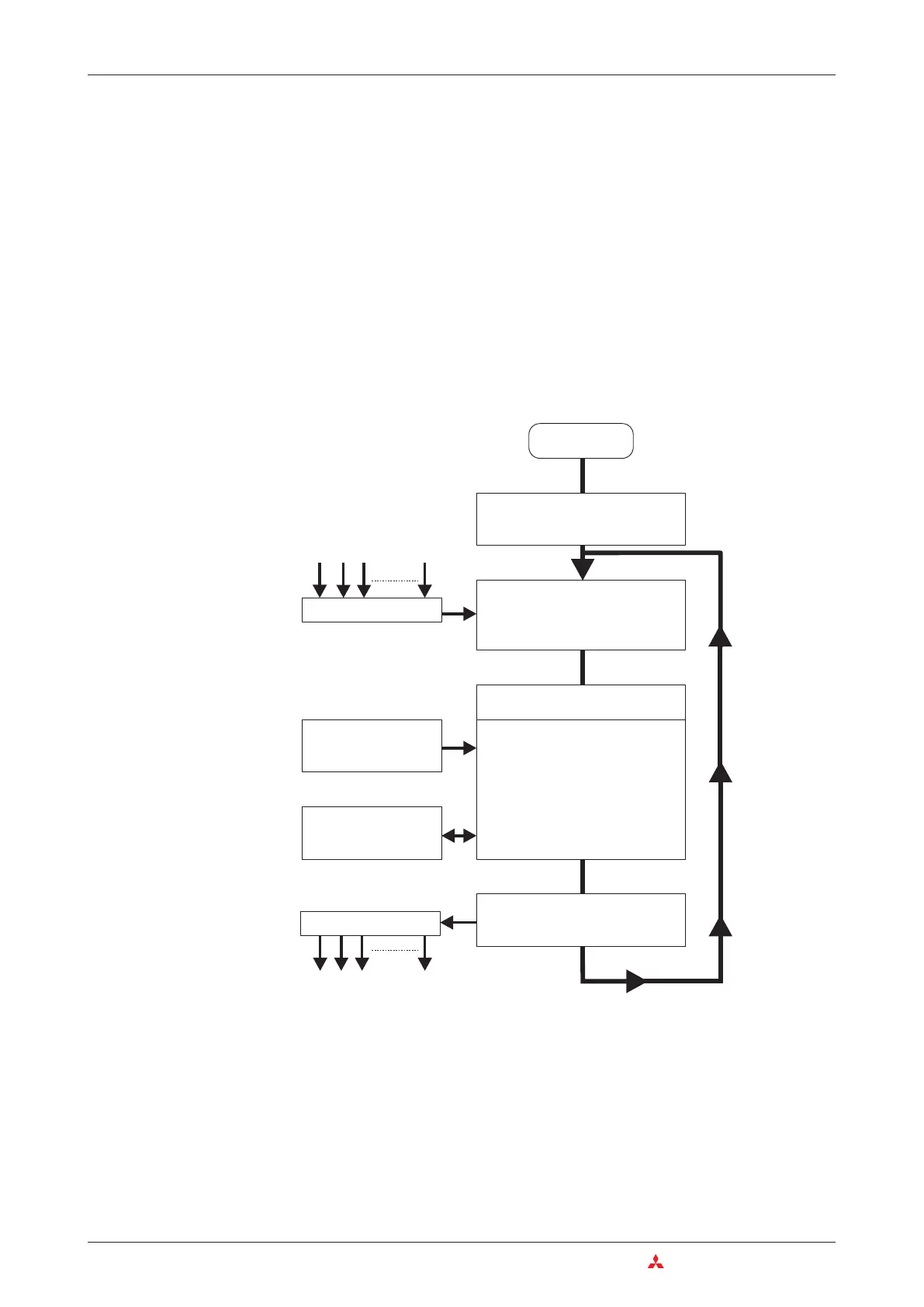

2.2 How PLCs Process Programs

A PLC performs its tasks by executing a program that is usually developed outside the control

-

ler and then transferred to the controller’s program memory. Before you start programming it is

useful to have a basic understanding of how PLCs process these programs.

A PLC program consists of a sequence of instructions that control the functions of the control

-

ler. The PLC executes these control instructions sequentially, i.e. one after another.The entire

program sequence is cyclical, which means that it is repeated in a continuous loop. The time

required for one program repetition is referred to as the program cycle time or period.

Process image processing

The program in the PLC is not executed directly on the inputs and outputs, but on a “process

image” of the inputs and outputs:

Input process image

At the beginning of each program cycle the system polls the signal states of the inputs and

stores them in a buffer, creating a “process image” of the inputs.

2–2 MITSUBISHI ELECTRIC

How PLCs Process Programs Programmable Logic Controllers

....

....

....

Switch on PLC

Delete output memory

Input terminals

Process image

of inputs

PLC program

Process image

of outputs

Output terminals

Transfer process image

to outputs

Instruction 1

Instruction 2

Instruction 3

Instruction n

Poll inputs and signal states

and save them in the process

image of the inputs

Input signals

Output signals

Loading...

Loading...