You can also specify the timer setpoint value with a decimal value stored in a data register. See

section 5.7.1 for details.

Retentive timers

In addition to the normal timers described above the controllers of the MELSEC System Q also

have retentive timers that retain their current time counter value even if the device controlling

them is switched off.

The current timer counter value is stored in a memory that is retained even in the event of a

power failure.

The device identifier for retentive timer is "ST". Similar to "normal" timers, retentive timers can

be programmed as low speed or high speed timers.

NOTE When shipped, 2048 (2k) normal timers are set in the parameters of an PLC CPU and no re-

tentive timers. In order to use retentive timers, the number of these timers must be set in the

PLC parameters.

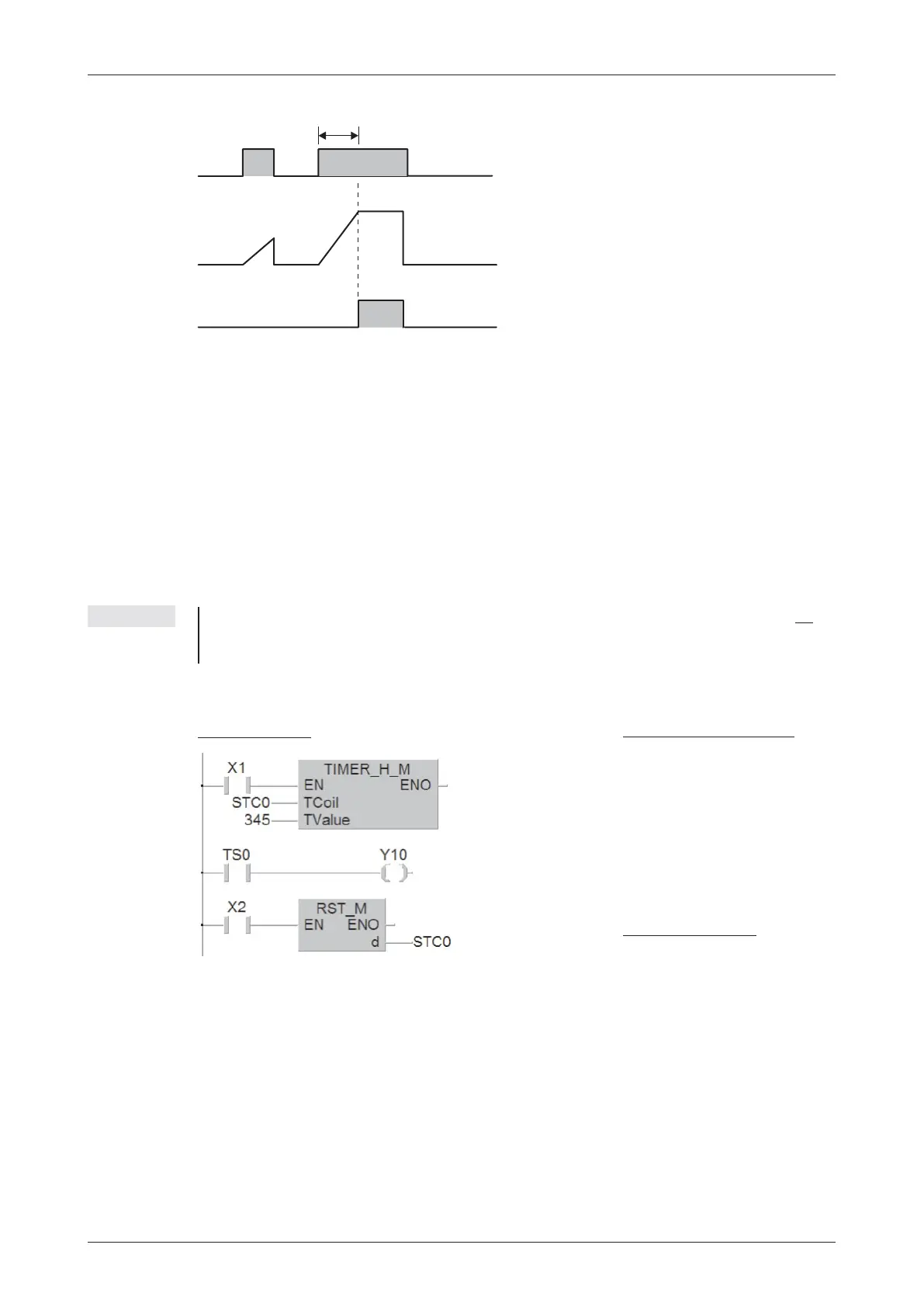

Example of a program using a retentive timer as high speed timer:

Timer T0 is started when input X1 is switched on. The setpoint value is 345 x 10ms = 3.45s.

When the setpoint value is reached T0 switches output Y10 on. Input X2 resets the timer and

switches its output off.

MELSEC System Q Beginners Manual 5 – 7

Devices in Detail Timers

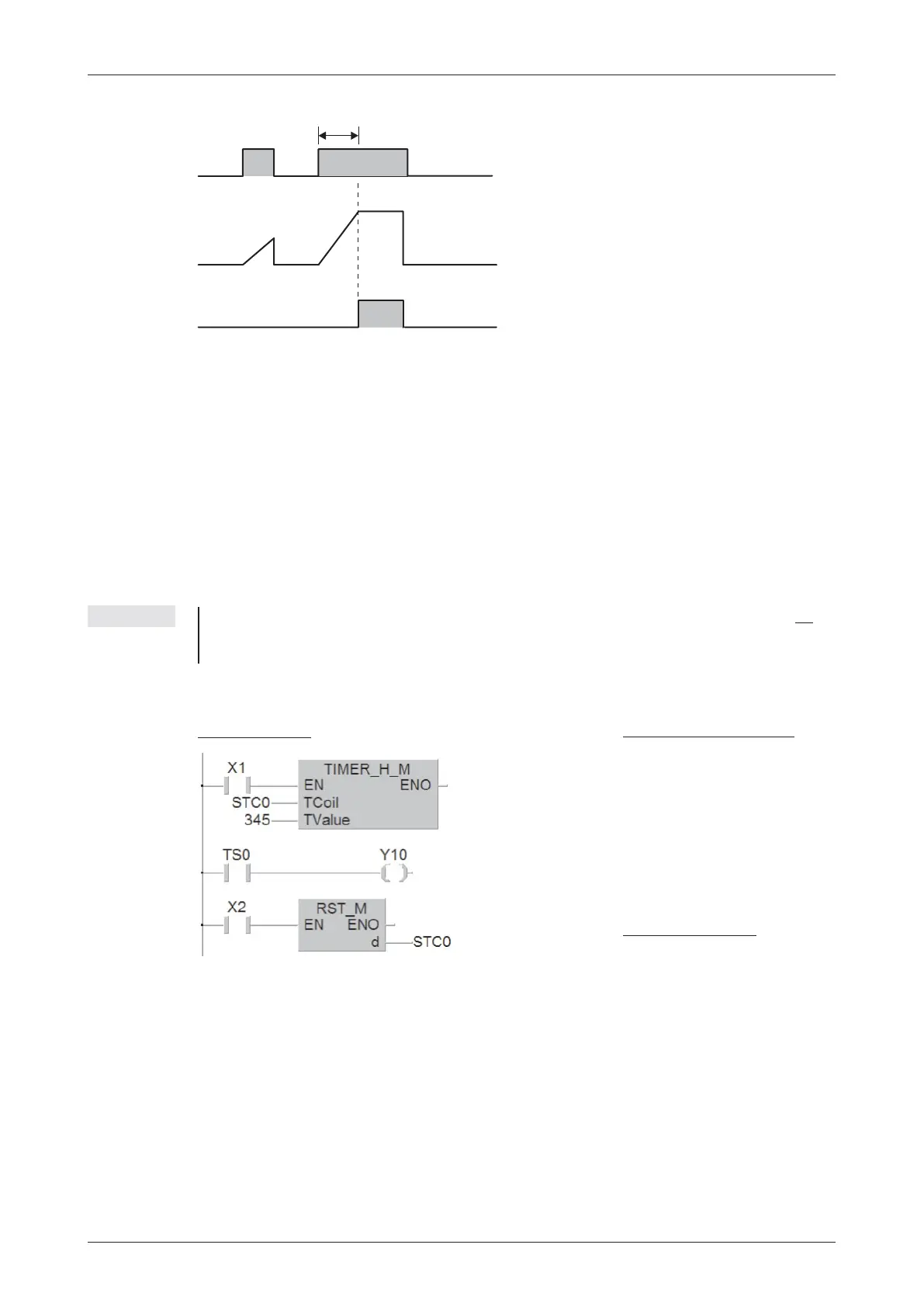

The timer continues to count the internal

100ms pulses as long as X0 remains on.

When the setpoint value is reached the

output of T1 is switched on.

If input X0 or the power supply of the PLC

are switched off the timer is reset and its

output is also switched off.

Ladder Diagram

MELSEC Instruction List

LD X1

OUTH ST0

K345

LD ST0

OUT Y10

LD X2

RST ST0

IEC

Instruction List

LD X1

TIMER_H_M STC0, 345

LD STS0

OUT Y10

LD X2

RSTC0

X0

T1

Y10

12,3 s

Loading...

Loading...