*

It is not possible to program the instructions FCALL, ECALL and EFCALL with the GX IEC Developer.

6–6 MITSUBISHI ELECTRIC

Applied Instructions Reference More Advanced Programming

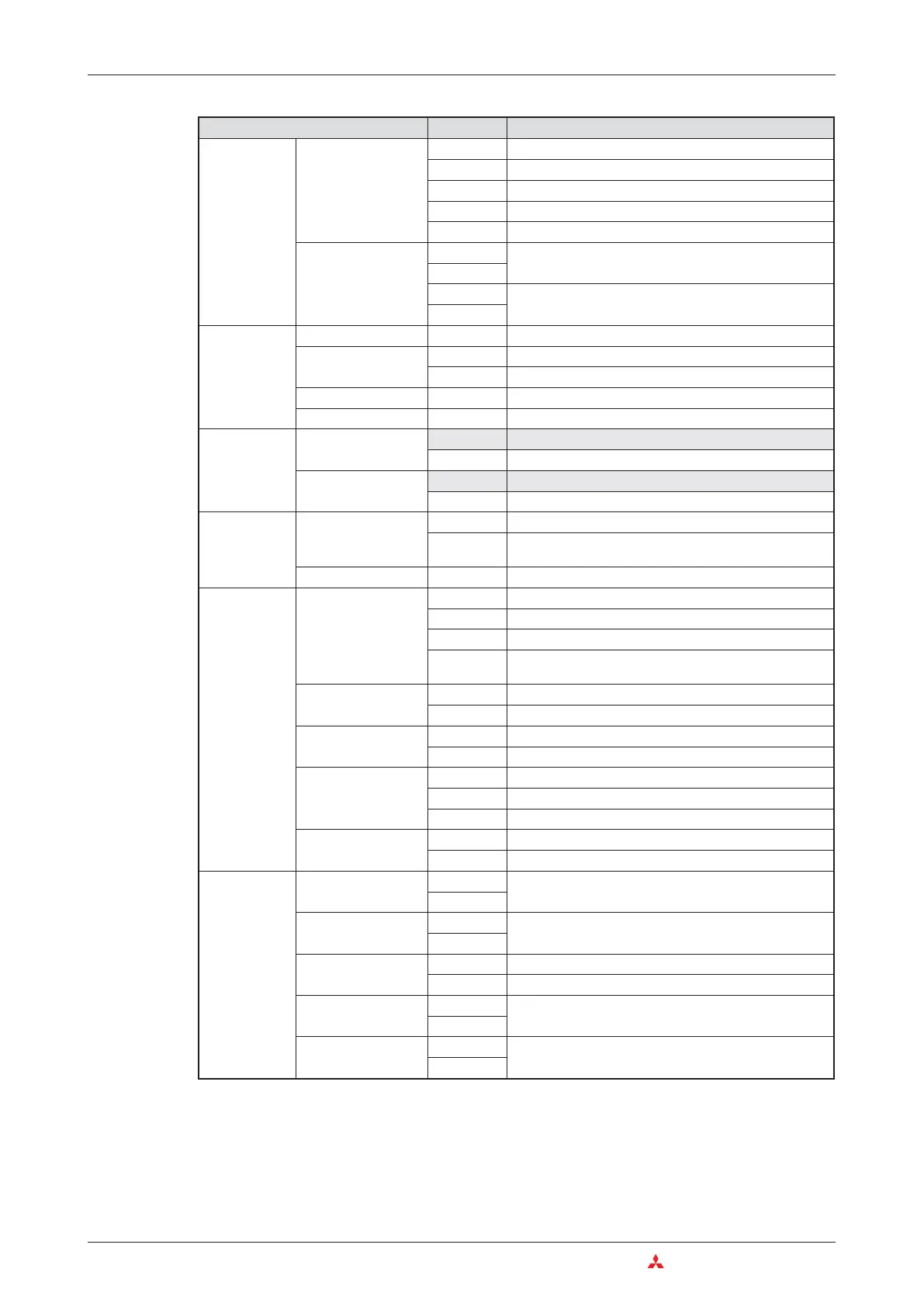

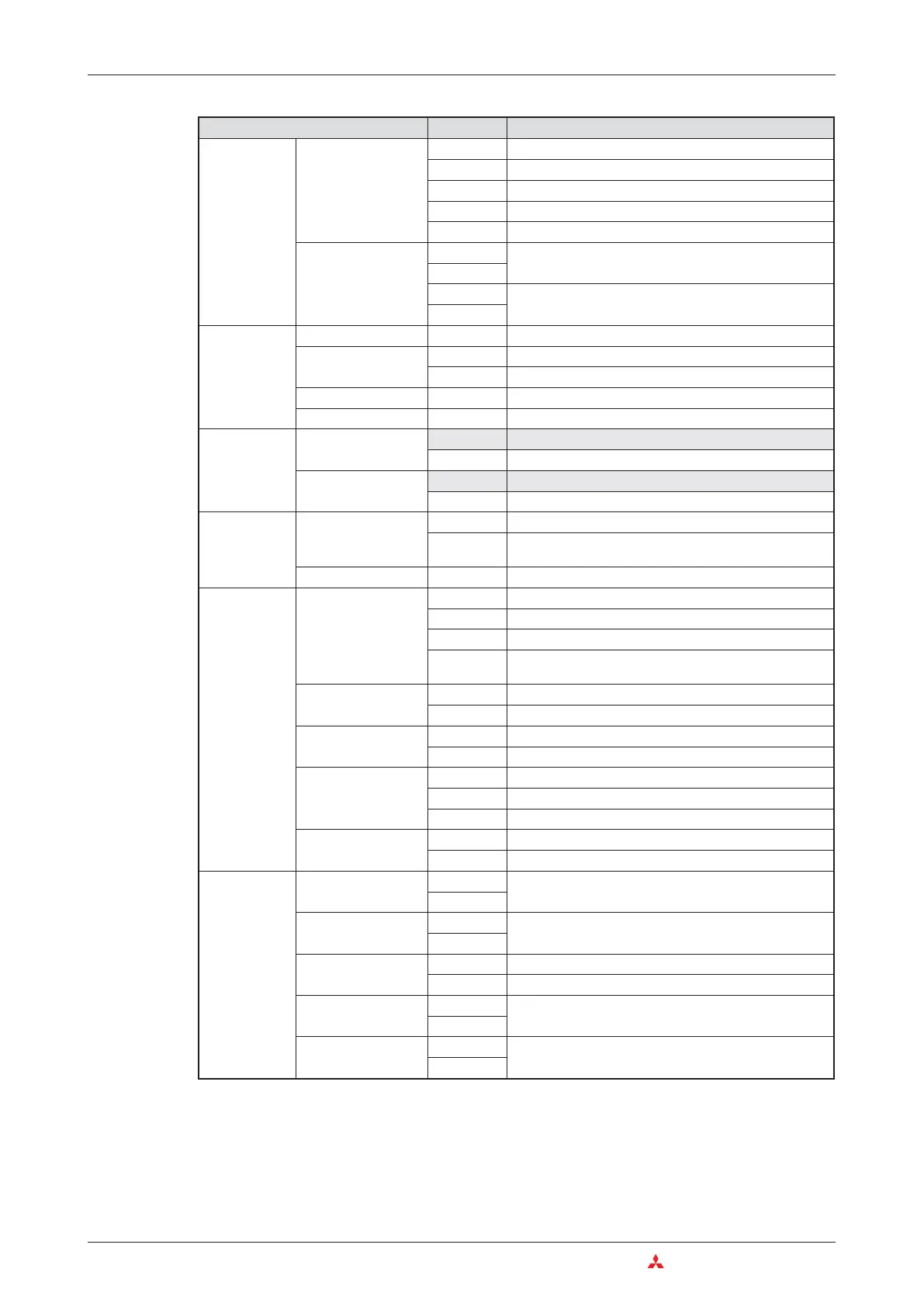

Category Instruction Function

Structured

program

instructions

Subroutine programs

CALL

Subroutine program call

RET

End of subroutine

FCALL*

Reset outputs in subroutines

ECALL*

Calling a subroutine program in a program file

EFCALL*

Reset outputs in subroutine programs in program files

Index qualification

IX

Index qualification of an entire program parts

IXEND

IXDEV

Store indexed device numbers in an index qualification

list

IXSET

Data table

operation

instructions

Write data

FIFW

Write data to a data table

Read data

FIFR

Read data entered first from data table

FPOP

Read data entered last from data table

Delete data

FDEL

Delete specified data blocks from data table

Insert data

FINS

Insert specified data blocks in data table

Buffer memory

access instruc

-

tions

Read

FROM

Read 16-bit data from special function module

DFRO

Read 32-bit data from special function module

Write

TO

Write 16-bit data to special function module

DTO

Write 32-bit data to special function module

Display

instructions

ASCII character

output

PR

Output of an ASCII character string to a peripheral device

PRC

Output of a comment (in ASCII code) to a peripheral

device

Clear display

LEDR

Reset annunciators and LED display

Failure

diagnosis and

debugging

Failure check

CHKST

Start instruction for the CHK instruction

CHK

Failure check

CHKCIR

Generate check circuits for the CHK instruction

CHKEND

End instruction for a program part with generated check

circuits

Store device status

SLT

Set status latch (Store device status)

SLTR

Reset status latch (clear device status)

Sampling trace

STRA

Set sampling trace

STRAR

Reset sampling trace

Program trace

PTRA

Set program trace

PTRAR

Reset program trace

PTRAEXE

Execute program trace

Trace

TRACE

Set trace

TRACER

Clear data stored by the trace instruction

Character

string process

-

ing instructions

Binary ->

Decimal (ASCII)

BINDA

Convert 16-/32-bit binary data into decimal values in

ASCII code

DBINDA

Binary ->

Hexadecimal (ASCII)

BINHA

Convert 16-/32-bit binary data into hexadecimal values in

ASCII code

DBINHA

BCD -> ASCII

BCDDA

Convert 4-digit BCD data into ASCII-Code

DBCDDA

Convert 8-digit BCD data into ASCII-Code

Decimal (ASCII) ->

Binary

DABIN

Convert decimal ASCII into 16-/32-bit binary data

DDABIN

Hexadecimal (ASCII)

-> Binary

HABIN

Convert decimal ASCII into 16-/32-bit binary data

DHABIN

Loading...

Loading...