This document and the information contained herein, is the exclusive property of MODE. And represents a nonpublic,

confidential and proprietary trade secret that may not be reproduced, disclosed to third parties, or otherwise employed in

any manner. whatsoever without the express written consent of MODE. Copyright © (2016) MODE. Allrights reserved.

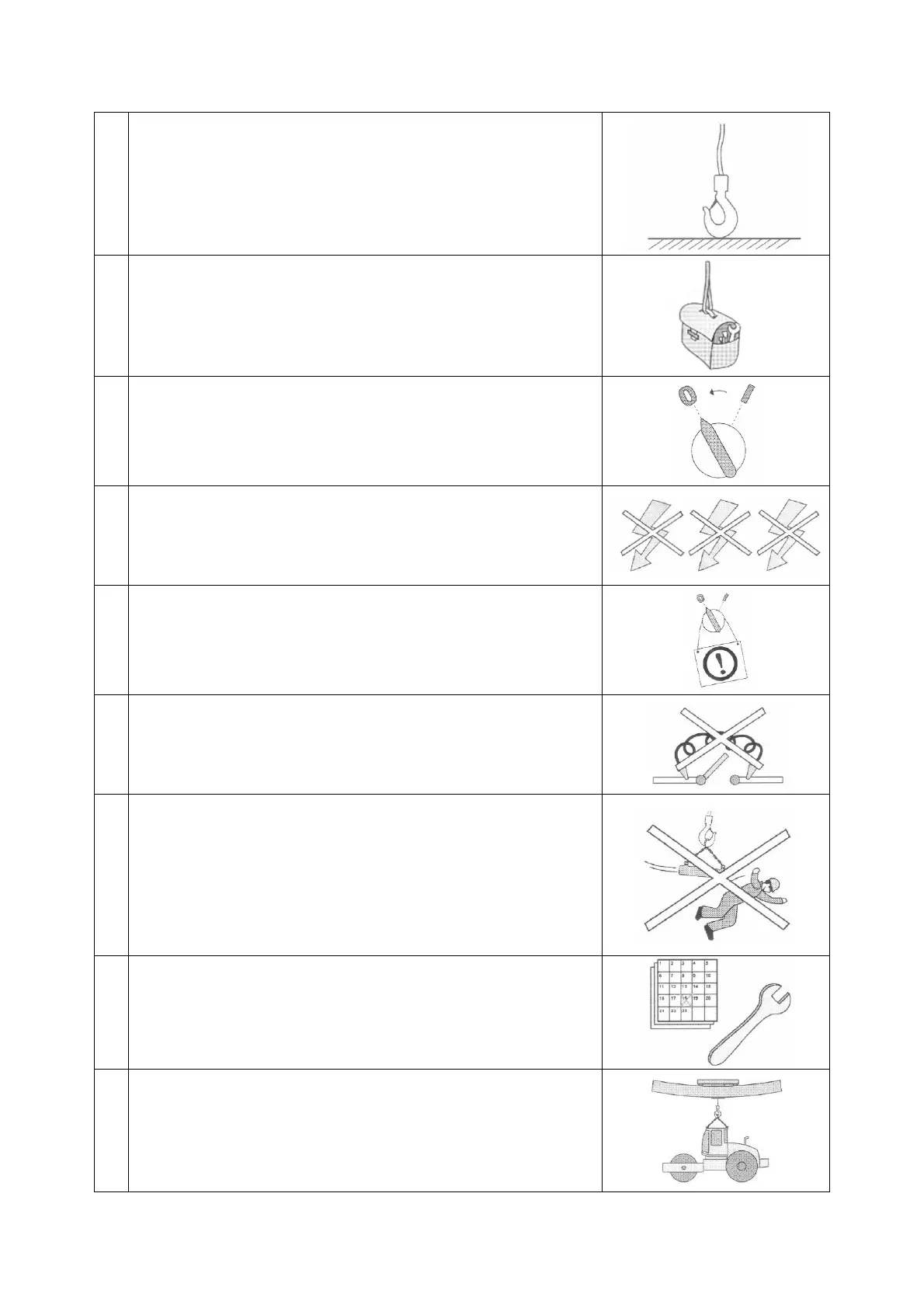

Ensure that there is no load on the lifting device

Before starting maintenance there should be no load on the hook or

lifting device.

Park the hook on the ground if there is any chance that the hoisting

brake will be opened during maintenance. A raised empty hook will

fall to the ground if the hoisting brake is opened.

Use hand lines for lifting and lowering tools

Hand lines, securely attached to the building structure, should be

used for lifting or lowering materials and tools. Use proper safety

equipment to prevent objects from falling when working in high

places.

Turn controllers off

All cor1trollers must be placed in the off position before starting

maintenance.

Verify that power is completely disconnected

Measure between the phases and between each phase and ground

to ensure that power is completely disconnected from the product.

Lockout-Tagout

The equipment power source must be locked out and tagged out

when necessary, in accordance with local regulations. See chapter

“Lockout-Tagout Procedure”

Safety devices must be restored to operational status

Ensure that any safety devices which have been bypassed

for-testing purposes have been restored to full operational status

before allowing the product to be used for normal operation.

Minimize the risks of moving machinery

Secure the area so that personnel are not at risk from the

movements of machines, automatic doors or adjacent cranes at the

installation site.

Ensure that machinery and equipment cannot start up accidentally

and cannot move during installation and servicing.

Be prepared in case equipment moves in the wrong direction during

testing.

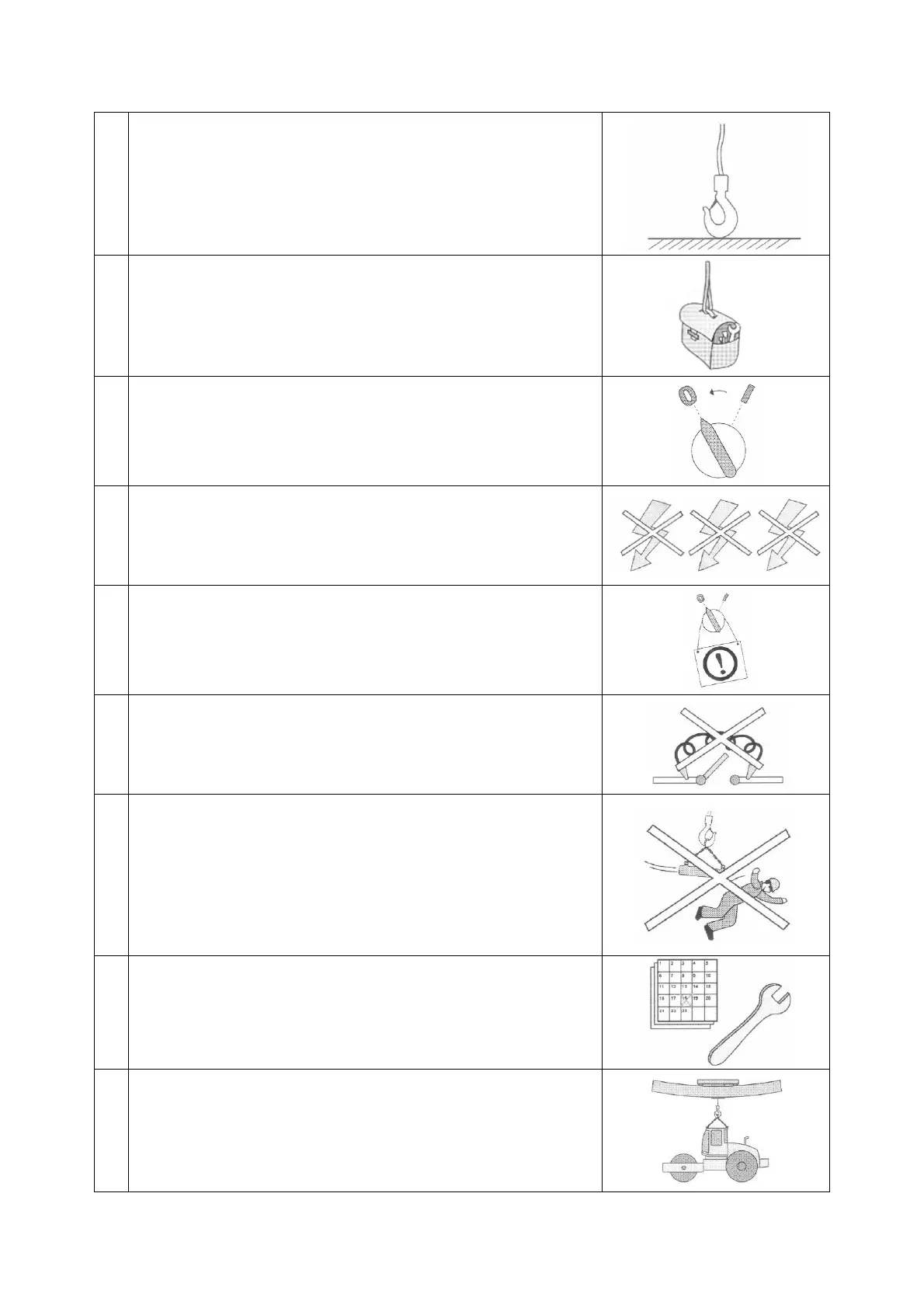

Perform regular inspections and preventive maintenance

To ensure ongoing safe and efficient operation of the product, carry

out regular inspections and preventive maintenance in compliance

with the instructions. Keep a record of all inspections and servicing.

If in doubt, contact the supplier of the product.

Returning the product to operation after overload or collision

After an overload or collision incident, the appropriate inspection

and repair operations must be discussed with the supplier of the

product.

Loading...

Loading...